In the brewing industry, high operating temperatures and fibrous hop sludge can play havoc with pump equipment if it’s not specified correctly. When Scottish craft brewers Brewdog were looking for a reliable and robust pump solution, it decided to work with water systems specialist Filpumps and pump maker Xylem.

For the brewery team in Ellon, Aberdeen, there were seemingly two key issues with the existing pump system, resulting in increased costs and downtime needing a quick resolution. In the first instance, the fibrous quality of hop sludge was threatening to cause build-ups and blockages at the base of the conventional, flat-bottomed, packaged pump station – causing delays to the brewing cycle with plant downtime and expensive tankering costs. Secondly, where the effects of high temperature on pumps and float switches had not been considered during the specification of the existing system, there was a real risk to its efficient and effective operation.

The pump and why it was chosen

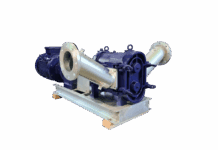

With this in mind, Xylem, working in partnership with local distributor Filpumps, recommended the use of its “warm liquid” N-impeller pump range. Alan Black, Field Sales Engineer at Xylem said: “Our close working relationship with the team at Filpumps meant that we could find the very best solution for Brewdog. Mark Elrick and Paul Brennan played a key role in specifying the “Flygt Experior” pump station, featuring the Flygt N 3153 warm liquid pump and a control panel complete with SmartRun VSD pump controller and Telemetry.

The Flygt N 3153’s high temperature feature, along with the self-cleaning technology of the N-impeller design, made it seemingly the perfect solution for the transfer of the problematic trade effluent at the end of the brewing cycle. Featuring “reverse run” & “sump clean/snore” settings, the innovative self-cleaning SmartRun controller helps to maintain the high-efficiency of the pump, says Xylem, while keeping the production processes moving. All-in-all this helps customers to reduce energy costs and cut the number of unplanned service calls.

The pump is equipped with a Class H motor stator with a design temperature of 180ºC max, compared to traditional Class F designs of 155ºC. Motor losses are also concentrated at the surface of the stator rather than the rotor, making it easier to transfer the heat into the pumped media.

In addition to the pump protection features, the Experior SmartRun package provides the full benefits of variable speed pumping and is designed to achieve energy savings and maximum cleaning within pumping stations. Flygt SmartRun offers variable speed controls; making it the perfect match for Flygt N-pumps while delivering reduced total expenditure for the end user.

The results

Offering the tough and hardy engineering solution that Brewdog was looking for, the team was so impressed by the success of the Flygt pumps, that Xylem and Filpumps were later invited to advise on the phase 3 expansion, resulting in a further order for a Flygt TOPS packaged pump station, Flygt Experior pumps and SmartRun technology.

Alan Black, concluded by saying: “The Brewdog team are renowned for their no nonsense approach, so we were really pleased to be invited back for phase 3 of the brewery expansion and it is testament to the team’s knowledge and understanding of this kind of application and the success of our products. As the Brewdog business continues to expand, we hope that Xylem and Filpumps will continue to be their pump partner of choice.”

With the success of this project worthy of a celebratory drink or two, Xylem in conjunction with Filpumps hopes to continue the partnership in the future.