Greg Brown of Flogas looks at how propane enrichment is used for injecting biogas into the gas grid – and explains why it’s an opportunity that more anaerobic digestion plants should be maximising.

Anaerobic digestion (AD) plants have long been using biogas generated from processing organic waste as a source of on-site renewable energy. However, taking the waste-to-energy concept one step further by turning this biogas into grid-ready biomethane is a fairly recent phenomenon, with the UK’s first biomethane-to-grid plants launching in 2012. Fast-forward to today, and grid injection is rapidly growing in popularity. The environmental and financial benefits associated with gas-to-grid, combined with effective, cost-efficient methods of propane enrichment are major drivers behind this surge.

So, what exactly is propane enrichment for biomethane, how does it work, and why do AD plant operators need to know about it?

The rewards

It pays to fully understand the commercial gains driving the rise of biomethane-to-grid plants. The environmental advantages of taking organic matter (whether food waste, sewage or purpose-grown crops) and turning it into energy that can be transported on a national scale are clear, especially to those already in the AD business.

Biomethane injected into the grid and subsequently used for heating and cooking across the country is eligible for regular payments under the government’s non-domestic Renewable Heat Incentive (RHI) scheme. This provides an attractive income stream for AD companies, so it’s easy to see why increasing numbers of purpose-built gas-to-grid plants are cropping up.

The science

However, while biomethane in its raw state can be used directly as a renewable fuel source (in combined heat and power engines, for example), it cannot be introduced straight into the national gas network – and therefore doesn’t qualify for RHI payments. This is because generally, the natural gas in the UK’s grid only contains around 90% methane, and has a varying calorific value (typically around 39.5 MJ/m3). Comparatively, the biogas produced during AD has a lower calorific value of around 36.5 MJ/m3.

This means it needs to be upgraded and enriched before it is suitable for the grid – and that’s where propane enrichment comes in. In short, this involves ‘spiking’ the biogas with propane (a form

of LPG, or liquefied petroleum gas), which has a higher energy content. This process ensures it has an energy profile that matches that of the natural gas used in the grid.

The results

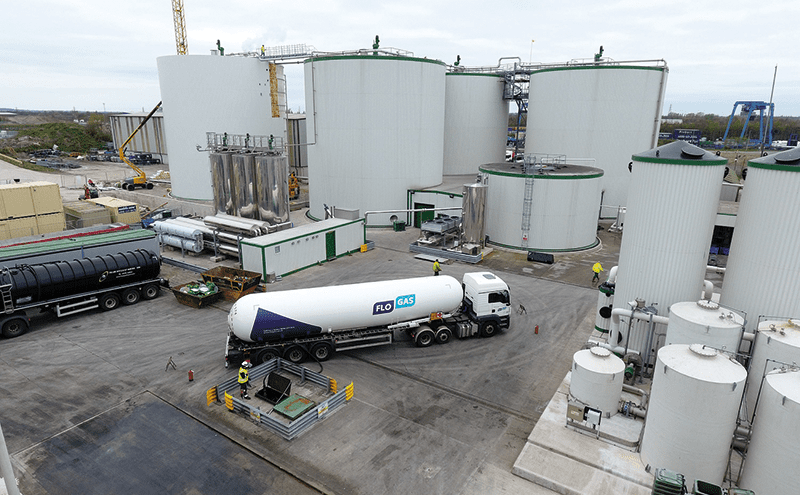

A working example of a site injecting biomethane into the grid in this way is food waste management company ReFood’s AD plant in Widnes, Cheshire, where we installed a specialist Flogas propane enrichment system in 2014. The plant is now generating enough biomethane to heat 10,000 homes a year, as well as benefitting from RHI payments in the process.

ReFood, which operates AD plants across Europe, opened its first UK plant in Doncaster, South Yorkshire in 2011 to generate grid-ready electricity. The company’s Widnes AD plant is its first purpose-built gas-to-grid site in the UK.

The site has three digesters, and a fourth one is currently under construction at the time of writing. The plant runs on feedstock made up of food waste from local shops, restaurants, prisons, schools and dairies – and throughout 2016, it delivered average monthly biomethane volumes of 782,000m3. Once the fourth digester has been commissioned, the plant will have the capacity to treat up to 160,000 tonnes of waste per year.

The process

So how do AD plants like ReFood’s Widnes site go about getting the right advice and equipment to facilitate propane enrichment? Nowadays there are expert energy providers that specialise in propane enrichment for AD applications, and can guide plant operators through every step of the process – from an initial consultation and site survey, through to system design, installation and regular propane provision. At Flogas, this is an area we have been specialising in since the first biomethane plants in the UK began operating several years ago. In fact, ReFood approached us for a bespoke solution after hearing about us through specialist trade shows.

The service and equipment available is different for every customer (depending on the unique challenges and requirements of the site in question). That’s why the system in place at ReFood’s Widnes plant was completely tailor-made to meet the site’s needs. Specified, designed and installed by our project management experts, it consists of a 22-tonne underground propane storage tank and a bespoke liquid propane injection kit. As a key partner, we also supply the plant with regular propane deliveries – and when the tank reaches an agreed level, an order is automatically generated by its in-built telemetry unit. The idea of this is to make the whole process as seamless as possible, and provide ReFood with valuable peace of mind.

The bottom line

One non-trivial consideration for plant operators investigating biomethane-to-grid is finding a propane supplier they can really rely on. It may sound obvious, but effective propane enrichment comes down to having a consistent, dependable supply of propane – without that, the commercials would never stack up. Establishing a strong relationship with your chosen supplier helps build trust and secures a direct line to the right technical expertise should you need it.