Firm says groundwater poisoning BTEX’s degraded in less than a month, lighter PAHs in under half a year and heavier PAHs and remaining aliphatic hydrocarbons in less than one year

Finnish environmental solutions firm Eko Harden Technologies Oy has announced (4 October) that completion of a year-long controlled test of contaminated creosote soil in Canada using its EKOGRID technology allows it to proceed with the development of a breakthrough in-situ solution for the environment.

Railroads authorities, oil and gas producers and timber firms can now use EKOGRID to eliminate the creosote health risk from soils previously considered untreatable and unreachable by current oxidation or bioremediation methods in the market.

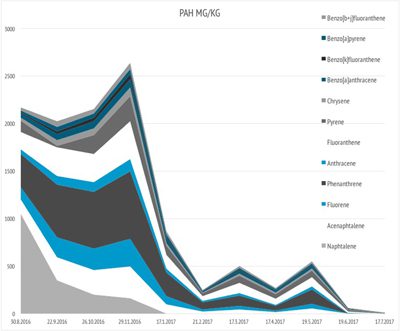

The completed test complements the firm’s earlier results recorded from measurements of contaminated soil samples from a number of customer projects. The results of the latest test speak volumes, says Eko Harden Technologies … groundwater poisoning BTEX’s were degraded in less than a month, lighter PAHs in under half a year and heavier PAHs and remaining aliphatic hydrocarbons in less than one year. Overall, the decomposition rate of the samples was about 1,500 mg of organic contaminant /kg soil /month.

“Creosotes today represent one of the hardest chemicals in the soils for remediation,” says Erkki Lindberg, CTO of Eko Harden Technologies. “EKOGRID technology is the missing link for cracking PAH compounds into more easily degradable forms and providing oxygen for soil microbes to finish the degradation process. This is a breakthrough on processes previously considered impossible in situ and the technology is now ready to be applied in any creosote contaminated environment.”

Creosotes are a category of chemicals formed by the distillation of various tars and by pyrolysis of organic material such as wood or fossil fuel. A mixture of hundreds of chemicals, they have widespread applications by various industries and are a major contaminant of soil, groundwater and sediments.

The major chemicals in coal tar creosote are polycyclic aromatic hydrocarbons (PAHs), phenol and creosols. Creosote is a thick and oily liquid and is easily set on fire. Its colour is usually amber to black and is the most common product used to preserve wood. Creosote has also been used as a pesticide.

Creosote can be released into soil and water and can then move through the soil to groundwater found underground in porous structures and spaces in soil, sand, and rock. After creosote gets into groundwater, it may take many years to break down. The chemicals in creosote can enter the air and can also build up in plants and in snails, shellfish and oysters, for example.

EKOGRID electro kinetic oxidation technology, says the firm, produces “a controlled low voltage electric field in a polluted area to amplify the remediation power of nature”. The patented technology has proven to be an ecological, sustainable and cost-efficient way for remediating the environment already in ten countries across five continents, according to Eko Harden Technologies.