The delivery of two Kompogas digesters for a biogas plant in Chongqing appears to mark the successful entry of Zurich-based Hitachi Zosen Inova – and its dry anaerobic digestion process – into the Chinese market.

Located in Sichuan Province and covering an area of 82,400km2, with a population of just under 30 million, Chongqing is said to be the largest city in the world. The Swiss firm has signed a contract to deliver two PF1800 Kompogas® steel digesters to German firm Bio Energy Technology (GBE) for a biogas plant project in the city.

For HZI and its local partner GBE, the plant in Chongqing is their first joint project. “In China, the composition of mixed city waste is often unpredictable, which calls for a certain degree of solid technological experience in this field,” said Markus Dicke, CEO of German Bio Energy Technology. Kompogas technology is the only one which is proven to fit this requirement, he said, promising optimal biogas production. The decision to choose HZI was taken at an early stage, he added.

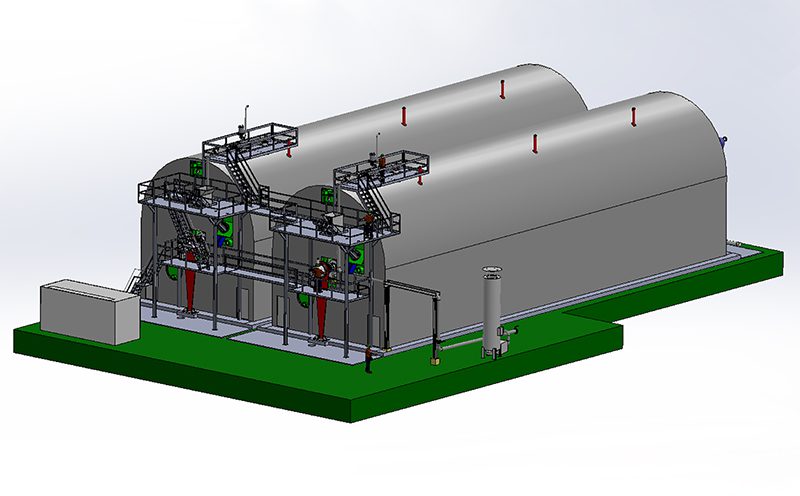

The biogas plant will be constructed at a local waste disposal site, where the deliveries of household waste will first be sorted. The two digesters will then process up to 200 tonnes of the separated organic fraction every day, producing around 6.7 million Nm3/a of biogas and compost.

As a COP21 member country, China has made considerable efforts and investments in the area of sustainable environmental and waste management in recent years, and has also been turning its focus recently to the recovery of energy from organic waste. “For us as an international company, this project is a key milestone in establishing a foothold in the highly competitive Chinese market. We are also proud of the contribution we are thus making to sustainable waste management in China,” said Andres Kronenberg of HZI.

With regard to China’s environmental objectives, HZI is also making an important contribution in the area of thermal waste treatment. In collaboration with its local licensees and clients, the company has recently been able to install its proven reciprocating grates in major thermal EfW plants, including three grates for the project in Changshu, a grate for the expansion of an existing facility in Yiwu, and a further grate system earlier this year in Jieyang.

Kompogas digesters are available in either concrete or steel construction in multiple sizes. Both series are equipped with the same robust agitator components and can be deployed for all input materials (bio-waste, green waste, organic elements from the general waste collection). The feed and discharge technology is adapted to the specific requirements of the respective input material. Two, three or more digester modules can be combined to form larger plants.