While the principal element of Building Information Modelling (BIM) is associated with the built environment, and more specifically deemed the role of specifiers and architects, the benefits for the water industry are also great. Jamie Mills, Systems Engineer at Xylem and member of the BIM4Water Steering Group explores the relevance of BIM for the water industry and the lessons that can be learned from other sectors.

Building a new commercial office space may seem far removed from the building of a new water industry asset, but there are similarities. The water industry has embraced BIM into its day to day operations, but there are some key differences in terms of understanding the methodology. Although the strict definition of BIM relates to building information modelling, we like to see it more as better information management; enabling more efficient design processes, construction and operation.

The principle methods of BIM have worked well in architecture, construction and building services for many years, so it is only logical that this now extends to other aspects of the built environment. In fact, following the UK Government’s mandate for BIM Level 2 on centrally procured construction projects, the method has gained considerable recognition amongst other industries. Globally, there will be ever growing interest in the methods of BIM with the forthcoming release of ISO19650 which will describe the organisation of construction work using building information modelling.

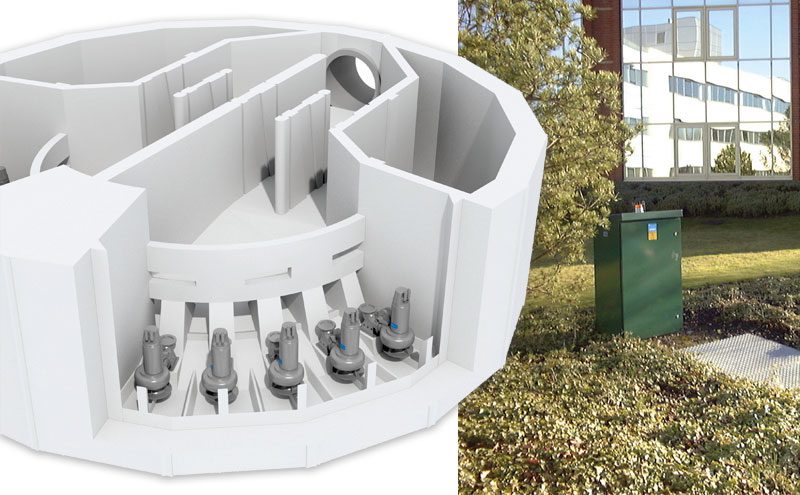

A typical water asset such as a pumping station is in fact an incredibly complex system that requires the skillset of a number of cross-industry specialists. Of course, pumping stations are intrinsically different to a building, not least from the perspective that pump sumps are below ground and buildings traditionally above it and inhabited. While the principles of BIM remain the same, it presents a number of potential questions and/or issues, all of which are being debated through BIM4Water – a dedicated group of individuals from across the water industry, who have come together to devise a mutually agreeable strategy to help facilitate BIM within the sector.

Outlining the delivery process

The construction and delivery of a water asset using BIM level 2 requires clear definition of the owner operator requirements. A project brief and Exchange Information Requirements (EIR) provide specific technical details about information drops, data environment structure, timescales and methods of data transfer. These describe the architecture of the Asset Information Model (AIM).

Once the project is complete, the information from the Project Information Model is handed over to the client in order to update the AIM. Using these structured methods removes any ambiguity from the delivery process and provides formal constraints for the design team to work within – helping to reduce any errors at handover. Parties work within project containers which contribute towards a Common Data Environment (CDE). This consists of a graphical information model and a non-graphical asset database. The key benefit of container based working, is the ability for teams to work together and within specific volumes. For example, civil, mechanical and electrical engineers are able to collaborate, avoiding the collision of services within installations.

The non-graphical asset database captures all documentation including constituent product technical details and a naming convention provides a reference for these within the CDE. These technical details are captured within Product Data Sheets which are supplied by manufacturers. For example, pumps are referenced in a particular manner which indicates their type, location and what specific project they are installed on. Conventional information about performance and maintenance is also given. The main benefit here is the ability for specification teams to contrast and compare products and systems with other similar solutions. For example, it would enable the itemisation of spare parts within a whole life cost analysis resulting in a more accurate prediction.

Benefits

The combined process of designing in a graphical model alongside a geographical information system and non-graphical asset database supports augmented reality, and the ability to build off-site, both of which improve safer practices of work in construction and facility management.

One example of this is the construction of packaged pump stations and wastewater treatment plants whereby manufacture, assembly and testing is completed away from site and the asset is set into a location using a single crane visit. This dramatically reduces the construction team’s time on site and their exposure to risk.

The methods also allow physical modelling of hydraulic structures and pumping stations to become more efficient. The 3-dimensional design will allow direct import into computational fluid dynamic analysis, without lengthy redraws from traditional 2-dimensional files. Further technologies are also becoming available such as additive manufacture for rapid prototyping, or 3-dimensional printing – this enables design teams to physically review the models before sign-off into construction.

Going forward

In the beginning, many may have been reluctant to embrace change within the design, construction and installation of water industry assets using the methods set out by BIM. However, as the benefits become clear, our industry is responding, which in turn is driving efficiencies across the supply chain. This is ultimately the goal of BIM, and we must now ensure its legacy, which will mean the continued sharing of knowledge and product data, resulting in better customer service.