German stainless steel products supplier Erich Stallkamp will be exhibiting a number of tank products aimed at the wastewater industry at the forthcoming IFAT show (Munich, 14-18 May).

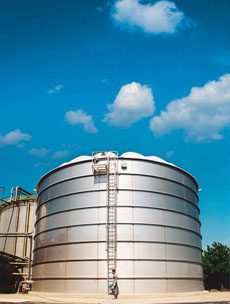

A press release from the firm suggests its claim to have “the necessary know-how” is proven by various projects from the last 25 years. In one application, an extensive wastewater treatment plant with two steel tanks (Ø15.52m, h=8.78m) was designed and installed in Bavaria as a wastewater collection tank. In another application, a corrugated steel tank (Ø2.75m, h=8.78m) was provided to serve as an equalising tank for the paper industry.

The firm has also provided large wastewater pre-treatment plants for the food industry, giving the example of a plant in North Rhine-Westphalia, which deployed a stainless steel tank (Ø16.29m, h=10.03m) with self-supporting ribbed dome roof and various add-on parts.

Special designs

Bespoke and specialty designs are also seemingly within the firm’s range. In Herzebrock, for example, a sewage treatment plant with several clarifiers (Ø outside 24.00m, Ø inside 3.88m, h=4.18m) was developed, which is controlled by means of overflow heights. In another design, funnel-shaped secondary clarifiers (Ø top 7.65m, Ø bottom 1.40m, h=5.00m) have been implemented, with a toothed gutter. This was for a private brewery, and has seemingly provided a great deal of stability and longevity.

Currently, a wastewater project with three stainless steel tanks for an automobile manufacturer in Ingolstadt is being implemented. One of the tanks is a sludge storage tank for flocculated sludge (180 m³), which is equipped with many attachments and agitator technology. In addition, two clean water tanks (each 120 m³) are supplied. All three tanks are constructed with a self-supporting stainless steel roof.

Why stainless steel?

The firm says the decision to use stainless steel is always worthwhile, since “the follow-up costs for maintenance and repair are reduced to a minimum.” Stainless steel owes its resistance to corrosion to a simple chemical reaction: due to its chromium content, an ultra-thin chemically resistant passive layer forms on the surface in conjunction with oxygen in the air or water. If the passive layer is damaged by external influences, it will form a new layer from the matrix of the stainless steel. Unlike other materials or material combinations, stainless steel can be completely and easily recycled after use.

In addition to high-quality stainless steel tanks, Stallkamp also offers the associated pump and agitator technology. For special use in waste and clarification tanks, a full stainless steel mixer is recommended, which is designed for stirring liquids with a variable pH value, generally from pH 5.3 to pH 8.1 at room temperature of 20°C. The Stallkamp portfolio also includes separation technology, which is produced for a wide variety of applications and dry matter contents.