David Bowers of ABB Measurement & Analytics makes the case for using thermal mass flowmeters to measure biogas flows.

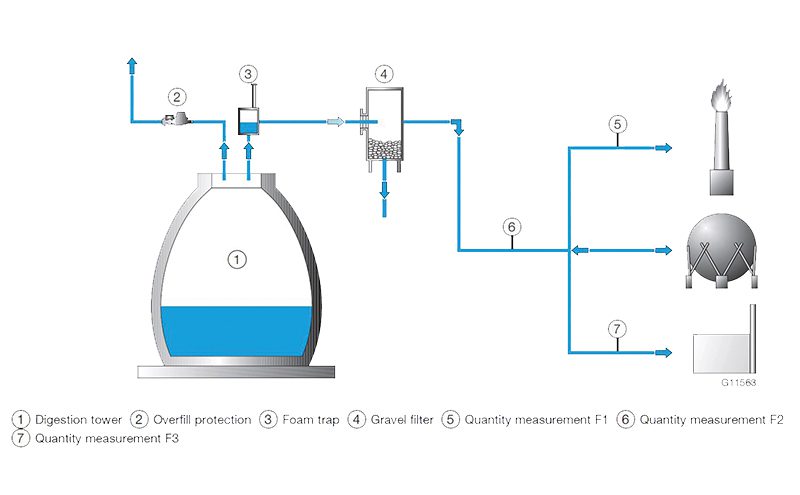

Utility companies and sewage treatment works use anaerobic digestion as part of the process to treat biodegradable waste and sewage sludge. This produces biogas, a mixture of methane, carbon dioxide and traces of other contaminant gases.

Methane, hydrogen and carbon monoxide can be combusted to produce energy, either through burning in boilers or passing them through a combined heat and power system. Often the electricity and waste heat generated from these processes are used to warm the digesters or to heat buildings, with excess being sold to suppliers or fed back into the local grid, providing an additional revenue stream.

During anaerobic digestion, microorganisms break down the organic matter contained in the sludge and convert it into biogas which can be used for electricity, heat and biofuel production.

Accurate measurement of biogas allows the efficiency of the process to be calculated. It is particularly important to strike the right balance, as adding excessive biomass may render it inactive, requiring a cost-intensive restart. Too little biomass means less electricity and heat are generated.

However, there are certain difficulties to overcome when measuring biogas. In many cases, variations in the quantity and pressure of the biogas produced can be caused by factors such as the time of year, temperature changes during the digestion process and the amount of sewage sludge entering the treatment works. This can make it difficult for flowmeter technologies that measure volume flow and rely on pressure and temperature compensation to obtain an accurate mass flow measurement.

These problems can be overcome by using thermal mass flowmeters. Capable of measuring mass flow directly, they can provide a mass flow rate in kg/h without any additional measurements or calculations.

How do they work?

Thermal mass flowmeters for biogas applications work on the hot film anemometer, or thermal dispersion principle.

A heated platinum resistor is maintained at a constant over-temperature in relation to an unheated platinum sensor that is the same temperature as the gas flow. One of these resistors assumes the temperature of the flowing gas, whereas the other resistor is electrically heated and, at the same time, cooled by the gas flow. A control circuit applies heat to the resistor so that a constant temperature difference exists between the resistors. With a known and constant gas composition, the mass flow can be determined based on the relationship between the heater current and flow rate with no need for additional pressure and temperature compensation.

With no moving parts, thermal mass flowmeters are ideal for handling the wet and dirty conditions characteristic of biogas, which also contains high levels of particulates that can block most flowmeters. By eliminating the problem of clogging, the need for maintenance is minimised.

As well as being suitable to measure low flow rate, thermal mass flow meters are well to monitoring the anaerobic digestion process due to their low pressure loss. Because thermal mass flowmeters take measurements using two small probes on the end of an insert, they form only a minor obstruction in the surrounding flow. This means that correctly sized thermal mass flowmeters offer an extremely small pressure drop of between one and two millibars, which is important in this application where the gas pressure can drop to very low levels.

With a turndown of 100:1 they can also offer highly accurate measurement at particularly low and variable loads, with the resulting data available to be used to help optimise the efficiency of the anaerobic digestion process.

Installation tips for top thermal mass metering performance

To optimise measurement performance in anaerobic digestion processes, it is important to ensure thermal mass flow meters are installed correctly. Installation should be behind a foam trap and gravel filter to maximise measurement accuracy and reduce contact with condensate. Installing the meter in a 90° position can also afford protection against measurement interference caused by condensate. Further interference can also be avoided by fitting a water trap to capture water and moisture build up.

With their operational benefits, plus a low cost of ownership through the elimination of peripheral temperature and pressure equipment and the reduced need for maintenance, thermal mass flowmeters offer an ideal solution for biogas measurement applications.