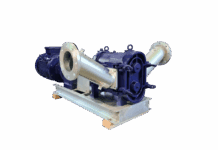

At an amine recycling plant, a Borger rotary lobe pump has been introduced to add sulphuric acid to an important neutralising process.

The new pump has replaced a screw pump that had reoccurring problems with its sealing system.

A sodium sulphate solution (created by the reaction between caustic soda and the sulphuric acid contained in the amine sulphate) is pumped to one of two storage tanks – with sulphuric acid mixed in on the suction side until the solution reaches a pH value of 7.

With air quality control requirements of high importance, the plant specified that the Borger rotary lobe pump be set to 8 bar. If the pressure drops below 5 bar, a pressure switch turns off the system. The medium pressure is restricted to a maximum of 3 bar by a pressure transducer, which ensures a minimum barrier pressure of 2 bar above feeding pressure.