Barry Hopton, Municipal Business Manager at atg UV Technology, a firm specialising in UV water treatment systems, says UV disinfection is reducing the water supply industry’s dependence on chlorine. He expands on the topic in this article

Since the introduction of the UK’s first public drinking water supplies in Victorian times, the preferred disinfectant has been chlorine, and its ability to provide a long-lasting residual to protect water in the distribution system means that it will remain an important factor in disinfection strategies in the UK.

However, there is increasing concern over its use as a primary disinfectant. Chlorine does have a number of drawbacks, not least of which is that liquefied chlorine gas is a very hazardous chemical. It is an expensive chemical with questions of sustainability, and some of its chemical reactions also raise questions.

Chlorine reacts with natural organic matter in water to form carcinogenic tri-halomethanes and discharging chlorinated water into the environment has clear implications. There are also concerns amongst consumers about taste and odour.

In parts of the Netherlands, drinking water is being supplied with no residual but, to do this successfully depends on the design and conditions in the distribution system. The UK’s drinking water infrastructure means that, for the foreseeable future, the industry will continue with residual chlorination to provide about 0.1mg/l of free chlorine at the consumer’s tap, but is also focused on reducing chlorine dosing elsewhere in the treatment process.

Ozone is an effective, but costly, alternative to pre-chlorination, and ultraviolet (UV) irradiation is gaining acceptance as a less expensive primary disinfectant.

With good reason, the water supply industry is very conservative, and the familiarity of chemical disinfection by chlorine or ozone, easily monitored by redox potential, is somehow reassuring.

However more and more water companies are discovering that UV as a primary disinfection strategy reduces the environmental, health and safety risks associated with large scale chlorination or ozonation and gives significant savings in both capital equipment expenditure and operational costs.

The efficacy of UV disinfection is dependent on the dose of radiation required to achieve a given log reduction in the microbiological load – the Reduction Equivalent Dose (RED) – and the ability of the UV equipment to deliver that dose consistently.

To achieve this, the applied dose has to be higher than the RED because some of the applied radiation is absorbed by the colour and turbidity in the water. How much is determined by the UV transmissivity of the water. The critical factor is how the applied UV dose is delivered and controlled, and that depends on the design of the UV reactor.

The German Deutsche Verein des Gas- und Wasserfaches (DVGW) validation protocol requires a reactor to deliver a minimum RED of 40mJ/cm2, and this is independent of the target microorganisms. In the United States, where UV disinfection has been used for water supply for more than a decade, the EPA takes a rather more rigorous view on validation.

Their Disinfection Guidance Manual, which has also been adopted by the UK’s Drinking Water Inspectorate, requires validation by independent 3rd party bioassay. This uses the log inactivation of specific challenge microorganisms passing through a UV reactor, in combination with known UV253.7nm dose-response relationships, to determine a corresponding RED.

The control system has to maintain this RED over the full range of works flows and UV transmissivities by monitoring UV intensity in each reactor and automatically adjusting the dose.

The first UV systems in the UK were, not surprisingly, installed on good quality borehole sources with high UV transmissivity and fairly constant flows. With experience, and growing confidence, the technology is increasingly replacing traditional chemical systems on surface water sources.

The growth has been impressive. The number of atg UV Technology systems delivered throughout AMP6 has topped 180, including plants for Affinity Water, Portsmouth Water, South East Water, Southern Water, Sutton & East Surrey Water and Thames Water, with more under construction.

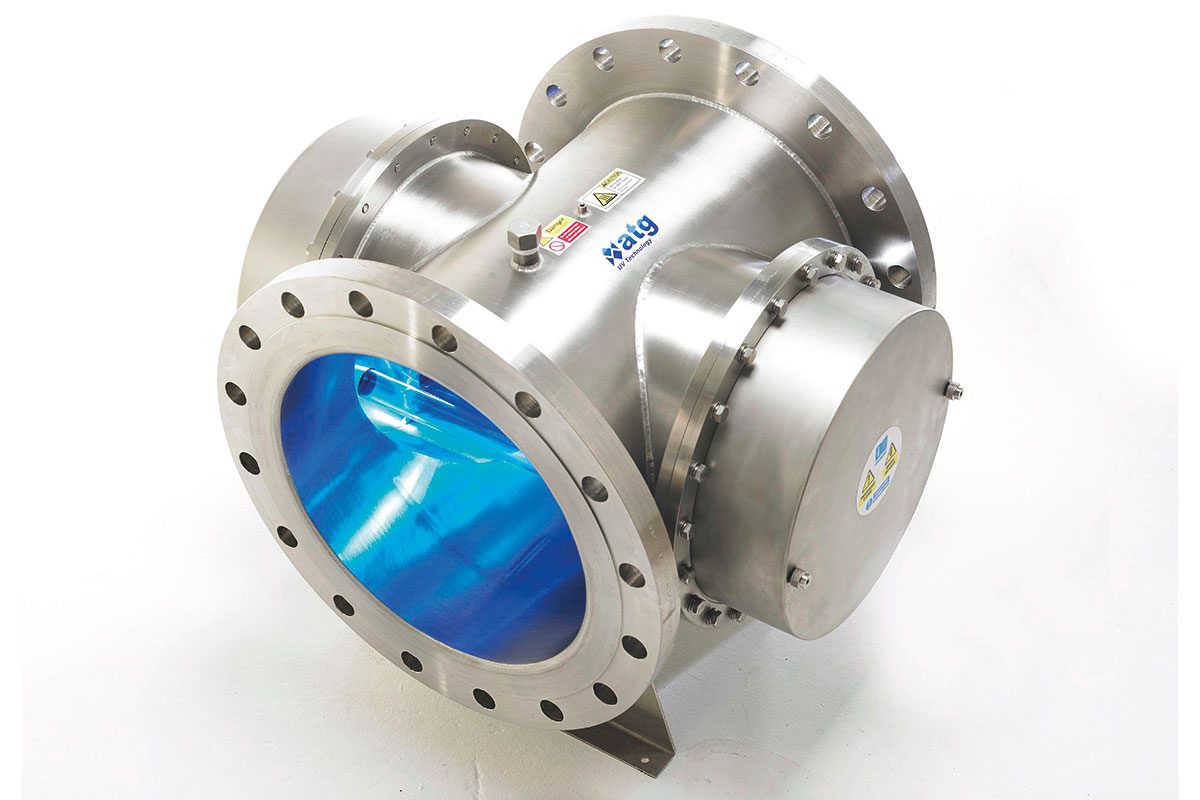

Part of atg UV’s success is due to nearly 40 years of experience covering industries from oil and gas to food and beverage and pharmaceuticals, and also that the atg UVLW reactor is one of only a few available products capable of treating water with UV transmittance as low as 49%.

So the future looks good for UV disinfection but manufacturers are far from complacent. New developments include high output, ultra-efficient 800 Watt Amalgam UV lamps like atg UV’s 800 Watt UVLX series.

These offer a range of benefits including guaranteed lamp life of 16,000 hours, optimized UV reactor design for reduced headloss and a low installation footprint. The ultra-high output of the 800 Watt Amalgam UV lamps reduces the number of lamps, quartz and seals by over 66% by comparison to traditional 330 watt systems, giving significant capital and operating cost savings.