German tank maker Stalkamp has recently supplied a very large, stainless steel tank, intended to house glycerin, for fermentation purposes.

The facility, in Hammel near Aarhus (Denmark), is using the 4.500m³ tank to store glycerin with a pH value between 3.5 and 8. This is a waste product from the production of biodiesel.

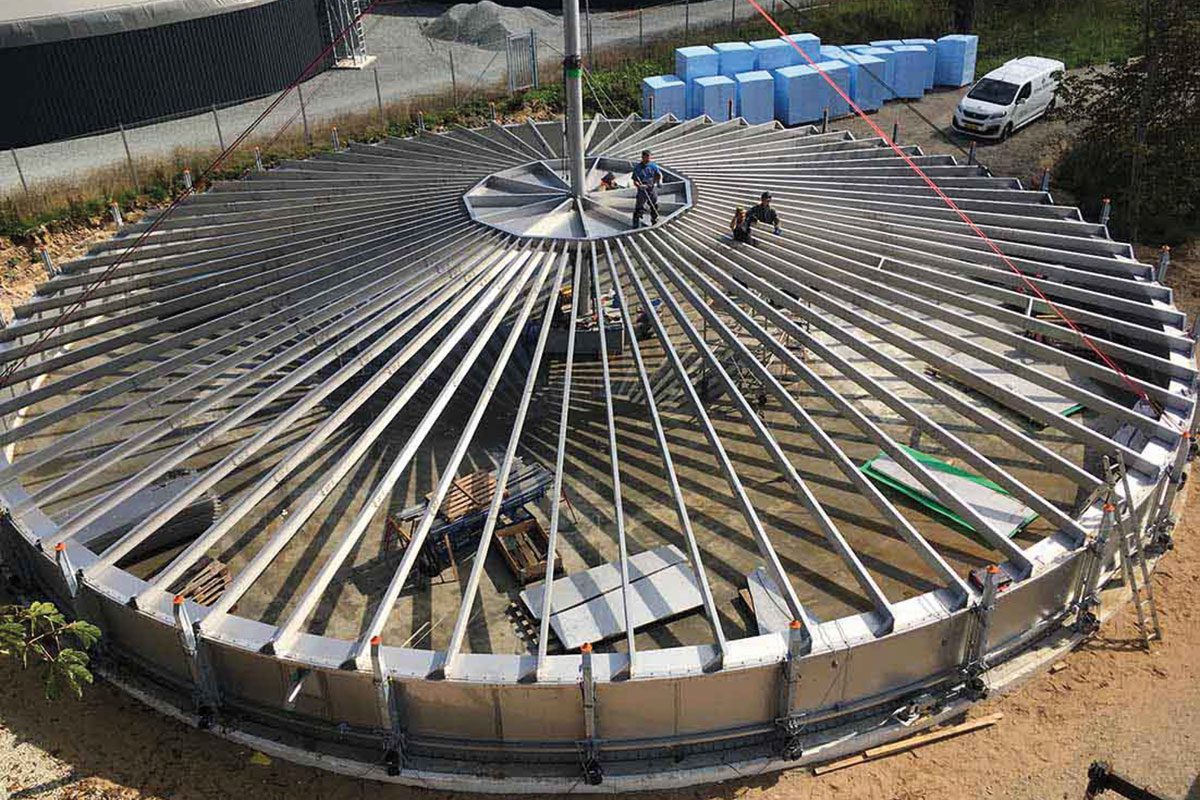

The project is part of an existing biogas plant generating two megawatts of power. The diameter of the new tank is 25m with a height of almost 9m. It is constructed with stainless steel shell plates in a segment-like design. At a height of almost 9m, seven rings of shell plates are necessary.

The digester is covered with a stainless steel roof pillared by a central support. It is composed of an inner and outer screwed element, with the outer ring attached to the top of the tank. There is an incline of 10°. The roof is designed for insulation and cladding, and has two inspection openings.

Equipped with a heating system and full insulation it has the basic accessories of a digester, in addition to two gas-tight wall bushings, two working platforms with ladders and three powerful submersible motor agitators in stainless steel.

The enormous size of the tank presented certain constraints at the construction phase. After the assembly of the first ring including the roof, the whole digester was elevated by an electrically-powered lifting system.

37 pillars were used to lift up the first ring and another four we needed to lift up the central support as well. Then the second ring was assembled and the tank was lifted several times until the seventh ring was constructed.