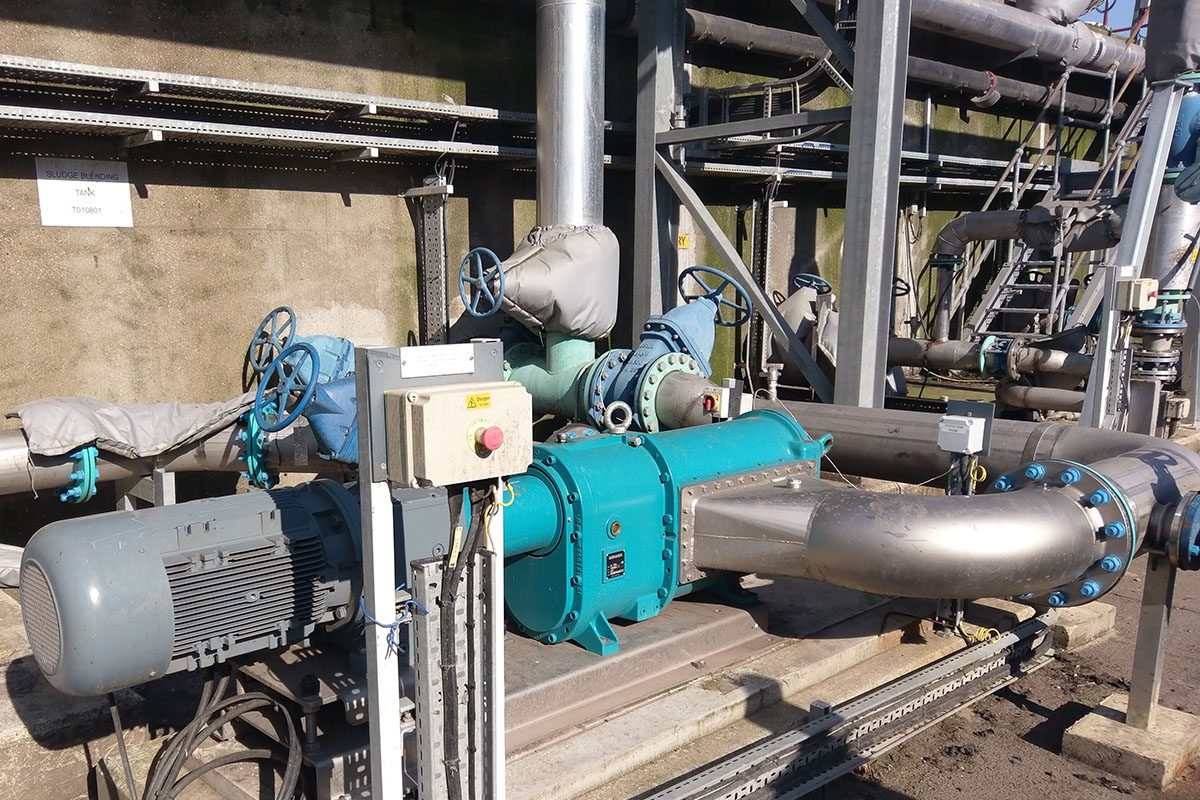

A new Borger pump at Cliff Quay Wastewater Treatment Works is said to be significantly improving the blend of liquified sludge and cake for Anglian Water’s anaerobic digestion (AD/biogas) process.

Working closely alongside Anglian Water and engineering firm Panks, Borger has also helped meet the challenge of mixing the contents of a rectangular tank that was proving too difficult for existing equipment.

Jon Hooper, Cliff Quay Treatment Manager for Anglian Water, said: “As well as bringing about a better, more consistent product to feed the AD process, Borger and Panks have effectively helped us solve a problem without needing to install a new tank”.

He added: “Mixing sludge in a rectangular tank is always a difficult task, but a paddle mixer at the deep end had difficulty coping with the solids, while the vortex pump at the shallow end of the tank (20m by 10m, 550m3) kept air-locking”.

To put the Borger EL rotary lobe pump to the test – and ensure that a new set-up would work for Anglian Water – Panks first tried pumping through the existing pipework, but there was too much pressure at the jet end”.

Chris Bone, Contracts Manager at Panks, explained: “We then tried with some temporary pipework in a different configuration and this mixed the tank much, much better.

“Despite the considerable limitations of a rectangular tank, there was no doubting the capability of the Borger pump, so together with Anglian Water, we agreed to install additional stainless-steel pipework with three injection points at strategic locations”.

Now, with cake that comes in at 17% solids, with the surplus activated sludge (SAS) at approximately 3% to 4%, Anglian Water are able to achieve the optimum level of 8% solids – without the previous air-locking and burn-out issues.

Anglian Water’s Jon Hooper added: “The mix of cake and liquified sludge is quite gritty, but since the installation by Panks of the new Borger pump, we’ve successfully improved the blend – which is quite an achievement with it running 24/7 and dealing with such high volumes – around 35 tonnes per day”.