Food waste processing expert Gemidan, whose innovative ECOGI technology processes food waste into a high-quality pulp-based substrate for conversion into renewable energy (using AD/biogas), has opened its second pre-treatment facility.

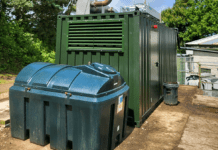

With a processing capacity of 50,000 tonnes, the new facility in Frederikshavn, Denmark (adjacent to a thermal energy-from-waste plant), produces a substrate for AD biogas plants that in terms of plastic contamination is at least three times freer from plastic than already very stringent Danish regulations require.

Rune Nyhuss, Director of Gemidan Group, commented: “The benefits to the world biogas industry of this ‘ultra-pure’ pre-treatment technology are huge. As any AD operator will tell you, grit from feedstock is an ongoing burden to performance, maintenance and efficiency – with downtime a major headache. At Gemidan we have been perfecting our ECOGI technology for over 5 years – and this new facility in Frederikshavn will have far-reaching bottom-line gains, as well as conserving water and preventing plastics from polluting farmland”.

Nyhuss went on to explain that more than half of the water required for ECOGI to process food waste is from 5,500m3 of harvested rainwater, which will be stored in a lagoon and treated by special separators to remove any grit or sand.

He added: “Feedstock for the new facility will come from source-separated household, industry and local business food waste. Inevitably, there will be plastics, glass and metals to contend with, but intensive independent testing during the 5-year development of ECOGI has proved that we achieve a substrate that is near 100%-free (99.96% to be precise) from non-organic physical contamination. Together with the ongoing success of our first plant in Holsted, Denmark, this is a major breakthrough”.