In an apparent industry first, a new facility will use organic waste to provide the heat and power required for the production of corrugated sheet board. The project has been undertaken by CorrBoard Bioenergy (CB Bio), a joint venture between packaging and display trade specialist Swanline Group and paper-based packaging producer McLaren Packaging, and has required a £5.5M investment.

The investment will facilitate the manufacture of carbon neutral corrugated material for use at Swanline and McLaren’s respective manufacturing plants in Staffordshire and Port Glasgow.

Some of the waste needed for the 6,400Mw / annum energy plant will be sourced from Swanline and McLaren’s packaging users who require compliant food waste disposal; thus providing a robust circular economy solution. Remarkably, the by-product from the plant is a quality fertiliser, pasteurised and certified to PAS 110, suitable for spreading on local farmland to aid crop growing.

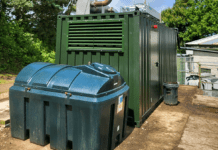

CB Bio is located adjacent to CorrBoard UK, the consortium-owned independent corrugated producer based in Scunthorpe of which Swanline and McLaren are part owners. Although autonomous neighbouring businesses, this innovative facility effectively makes CorrBoard UK’s production carbon neutral, providing an advantage to its customers and partners.

The concept for the CB Bio plant evolved after a chance meeting five years ago between Nick Kirby of Swanline and Robert Greenow of BioG-UK, an established operator of renewable energy facilities that use anaerobic digestion to generate energy. Once feasibility for the plant was proven, Greenow then designed the scheme and agreed to become the operational partner. BioG-UK also provides a network for collection of organic waste; the fuel for such a plant.

The plant has the capacity to divert 25,000 tonnes of biological waste from landfill to provide more than twice CorrBoard UK’s energy consumption, or enough electricity and heat to sustain 1,500 homes. The plant is modular in construction and therefore output capacity can be increased in future.

Additionally, both Swanline and McLaren expect CB Bio to substantially offset their own carbon footprints from the excess energy not consumed by CorrBoard UK but fed to the National Grid and allocated back to them in carbon credits.

Nick Kirby, CEO of Swanline Group said: “CB Bio is a bold statement to our customers who genuinely want to procure corrugated packaging with strong ecological credentials.”