To help achieve its carbon reduction target, Yorkshire Water says it has partnered with advanced materials manufacturer, Haydale, to trial a ceramic surface treatment designed to enhance and protect the water company’s concrete asset base most at risk from decay.

Traditionally, once a concrete structure reaches the end of its asset life, it would be demolished and rebuilt. However, using a ceramic surface treatment reinvigorates existing assets and expands the life of new structures beyond what is currently possible. Early indications also show there is a carbon reduction of 43% compared to some traditional concrete solutions.

Of the trial, Jonathan LeMoine, senior project manager at Yorkshire Water, said: “In early 2021 we will be using one of our capital partners to apply the material to a number of our chemical bunds. The results will be immediately apparent and will pave the way for a larger programme of works protecting our assets.”

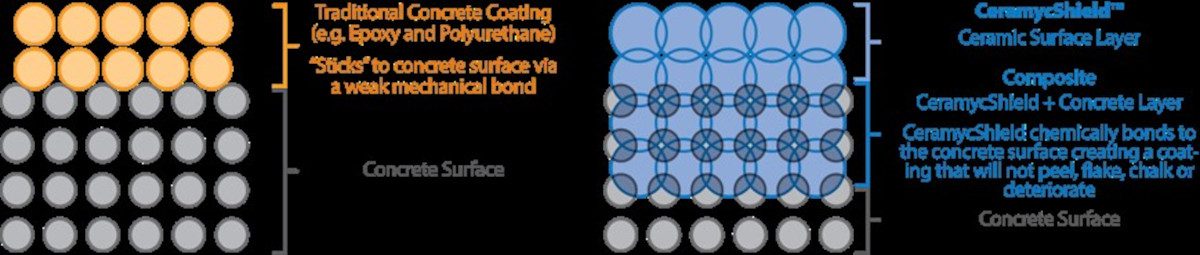

Haydale’s treatment uses alumina and zirconia silicates to renew and preserve concrete surfaces. The dense ceramic polymer wraps around and atomically bonds to all elements in the concrete, shielding the surface from the environment. It is not affected by wet/dry or freeze/thaw cycles, and does not peel, flake, chalk, or delaminate. It offers asset preservation and reduces concrete corrosion; stabilising the surface chemistry of concrete, stopping carbonation and environmental exposure-driven erosion.

Jonathan continued: “We often invest in trialing new technologies and techniques to pave the way for lower emissions in our CAPEX and OPEX solutions. We’re excited to see the results from this trial, and hope that it will provide a low carbon alternative to demolishing and rebuilding”.