The firm providing services to wastewater networks says its adoption of ‘spinning laser’ technology is helping to revolutionise its pipe profiling capabilities.

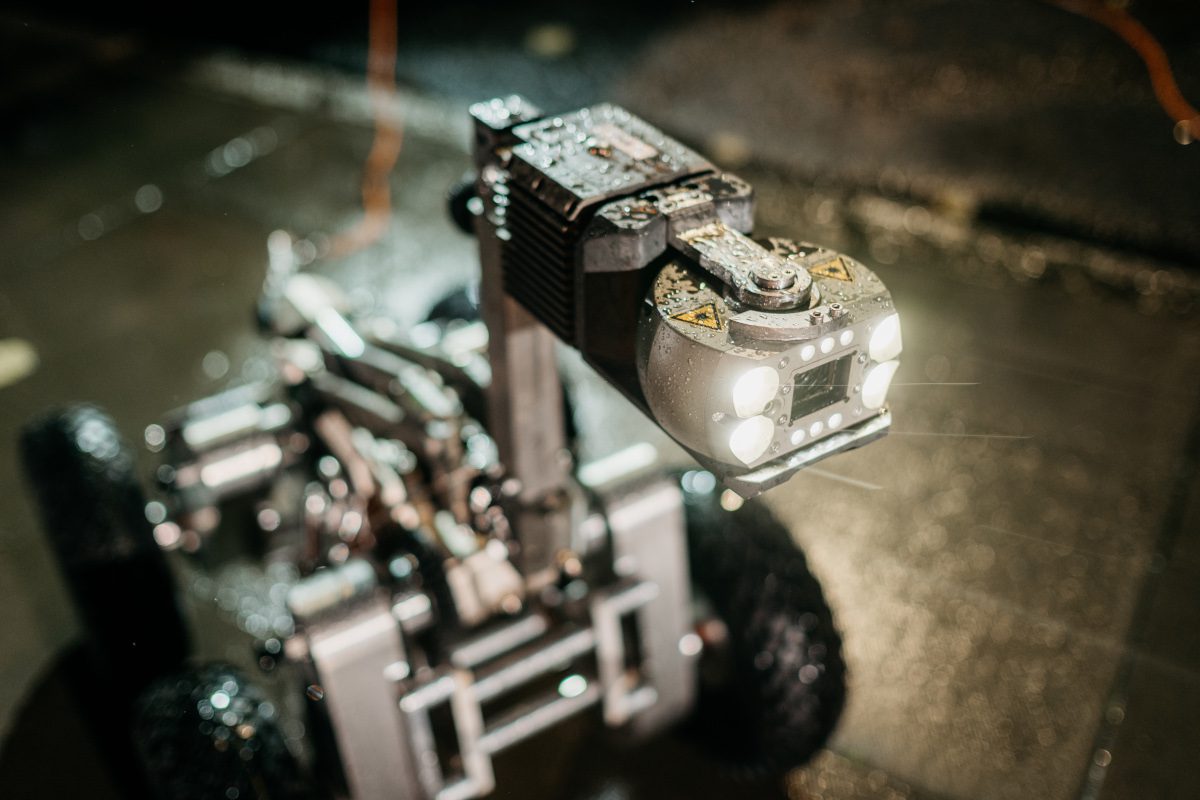

Available from IWJS, a part of M Group Services, the Rausch Mainline CCTV HD camera delivers high-quality digital images of pipes, with a twin-laser profiling system capable of scanning pipe diameters of up to 2.4m. The system accurately measures displacements, deformities, diameter changes and pipe wear, as well as measuring holes in broken pipework to help identify voids which can lead to huge collapses.

Designed and built in Germany, the system has the traction to climb over debris and displacements and, with an added egg-shape sewer kit, stabilisers and additional light packs, is able to manoeuvre easily to deliver high definition footage to IWJS operational teams.

Leah Nicol, IWJS Asset Data Delivery Manager comments: “This is a truly innovative technology that is allowing our engineers to accurately identify specific sections of pipe that are most at risk of failure, ensuring that targeted rehabilitation measures can be carried out before problems arise. The data provided, combined with digital and laser profiled manhole data, is enabling our teams to produce 3D models of the network and monitor defect deterioration with millimetre accuracy.”

How it works

The spinning laser pipe profiling technology is based on a three-in-one system, with two integrated laser diodes positioned either side of a conventional CCTV camera lens to perform CCTV pipe inspection, laser profiling (precise measurement of diameter, deflection and deformation of pipe) and crack and joint measurement. The laser diodes project laser dots onto the inner pipe wall, whilst the camera head rotates to measure the diameter, and all changes thereof, via triangular calculations. Working in conjunction with pipeline observation system management (POSM) software, the solution provides comprehensive scans that generate easy to use reports to profile the pipe.

Christopher Stewart, Managing Director at IWJS, comments: “We are delighted with our investment in this revolutionary CCTV pipeline technology. Innovation plays an instrumental role in our operational approach and the introduction of this technology will deliver clearer, pinpoint accurate surveys, detailed calculation of every CIPP liner, and 3D views of the design process, providing our clients with new levels of clarity on true pipe condition and understanding of their asset.”