One of the most significant recent developments in level measurement for containers and tanks is the emergence of a new class of seemingly affordable and high performance radar level sensors. VEGA Controls provides some background on this development and the firm’s Matt Westgate answers questions on issues such as the signficance of MCERTS certification for this class of sensor.

According to recently published figures from the Environment Agency, water companies discharged raw sewage into rivers in England more than 400,000 times in 2020. It’s reasons like these that make the reliable and accurate monitoring of all discharges into the environment so important. And why the EA places so much emphasis on schemes like MCERTS, because they ensure this monitoring is done correctly, regularly inspected and properly verified.

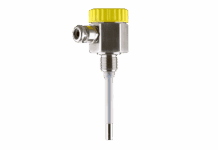

To make this more accessible to all water-industry users, VEGA has introduced a first for its 80 GHz compact radar: MCERTS Class 1 approval. VEGA has developed its own FMCW level radar chip to make the low-cost, high-performance yet compact level radar sensors available at an affordable price point.

But why use radar for applications as ‘simple’ as water level? It offers measurement unaffected by challenges such as changes in ambient temperature, and the build-up of condensation on the sensor. It is also an inherently more accurate all-conditions technology.

For example, legacy technologies – based on ultrasonic level sensing – require protection from solar gain/air temperature, as any undetected air temperature variations will cause a measurement error. This could mean that multiple sunshades, additional external temperature sensors or even dual measuring heads are needed to achieve the equivalent accuracy to a radar.

In a unique first for an MCERTS open channel flow measurement system, there is now the option to use the radars as a ‘standalone’ 2-wire loop powered radar transmitter. With no need for a local controller, making it ideal to use with telemetry systems, the 80GHz compact radar removes the cost, complexity and power needs for installing a remote controller/transmitter box.

A choice of digital communication using HART or current output also adds to the application versatility and accuracy – with local controllers optionally used for additional local display, datalogging, relay and pulse outputs for level alarms, for flow and triggering volume based samplers. Another unique capability is the single or twin channel measurement, which could be used to measure both flow through a structure and storm water spill level, for example.

Bluetooth set up and retrieval of measurement without the need for a local display can be done via an App making it safer and more convenient to use.

MCERTS: why is it so important for radar level sensors?

We believe this is an exciting ‘coming of age’ for radar in the water industry, showing that it’s got the credibility of class one certification. The performance and instrument cost also has the commercial benefits often associated with ultrasonic level systems.

We really feel we can outperform ultrasonic level systems head-to-head, proving its superior accuracy and resilience across a range of applications, which would include EDM related measurements, as well as more conventional open channel flow inlet and discharge measurement.

Another big first for us is the unique MCERTS certification that enables just the sensor to be the transmitter of the flow data, which means no extra controller or box on the wall is needed, saving time, cost and complexity and offering a much better solution for telemetry data loggers and the like.

Why is it so interesting for radar technology?

Maintaining an accurate level measurement in direct sunlight and varying ambient temperatures is incredibly important when it comes to EDM and open channel flow measurements.

Accuracy fluctuations occur when technologies affected by ‘solar gain’ or undetected temperature gradients in the air above the surface cause errors in the level measurement, which are then exponentially calculated through flow curves associated with flow structures.

There has also been the argument that the flow structures themselves have inherently low accuracy, therefore the ultrasonic based level and flow measurement does not show up its fallibility. However we believe you should get the best data you can, to minimise errors and maximise data accuracy and therefore exploit its value.

What applications do you see it being most useful for?

As a non-contact technology it is extremely flexible in how and where it can be applied, a level sensor that fits in the palm of your hand, has no dead-band and can measure up to 15m really covers a vast array of applications.

The radars have a number of ATEX approval options to choose from, so there really are no restrictions as to where it can be mounted. We feel that radar can play the key role in both underground assets and normal open channel flow measurements both in and out of treatment works, but of course the flexibility and capability of radar doesn’t stop there, it extends to sludge tanks and hoppers, digester level monitoring, chemical tanks and dosing systems, gravity blet thickeners, as well as clean water distribution.

We see the MCERTS certification being a foundation stone in that wall of applications and the final stamp of approval confirming its accuracy.

Isn’t radar more expensive and complicated to set up?

Actually this is a popular misconception. I have been working with and applying radar level sensors for the last 13 years, and it is great to see that the resilience and accuracy of this technology can now be enjoyed by the water industry at such an affordable price and compact design. The robust nature of radar technology means there is typically less that can go wrong and less scope for problems. They are easy to install, need less engineering input, are really quick to setup and don’t need a regular maintenance regime to ensure they are working correctly.

With regards to setup, we have the award-winning VEGA TOOLS app using Bluetooth communication, which is provided with all our new radars and controllers as standard. This offers quick, simple and safe connection to the instruments via an intuitive app with application-based setup. For example, when you need to verify the instruments current level reading, the app is the perfect platform for carrying out this task, especially on instruments with no in-head display or local controller/flow computer or where the location is difficult to access.

We see this as particularly useful in relation to EDM UMON3 measurement points, as the current draft product standards state that the sensor status, in relation to the spill point, must be accessible and verifiable by an MCERTS inspector or Environment Agency officer. The document states that viewing the level doesn’t have to be by a physical display but may also be viewed via an app.

Feedback from the engineers and operators in the field is that the app is easy to use, intuitive and most of all, timesaving. We feel that getting a better and more accurate setup first time around is crucial for data quality and saving time and money.

Why should organisations consider this technology change?

With the continuing development of radar chip technology and the lowering cost, we see radar sensors becoming the standard level sensing technology in the water sector in years to come.

When you combine that with performance gains, even marginal ones, lower engineering costs to install and easier set up, multiply that by hundreds of sites in the water network, it all adds up to a big potential operational and cost saving, and there are reductions in CO2 though reduced site visits, and materials.