GEA’s centrifuge technology for dewatering sludge is playing a key role in helping waste company Biffa’s recycling plants reduce plastic pollution and CO2 emissions in the UK.

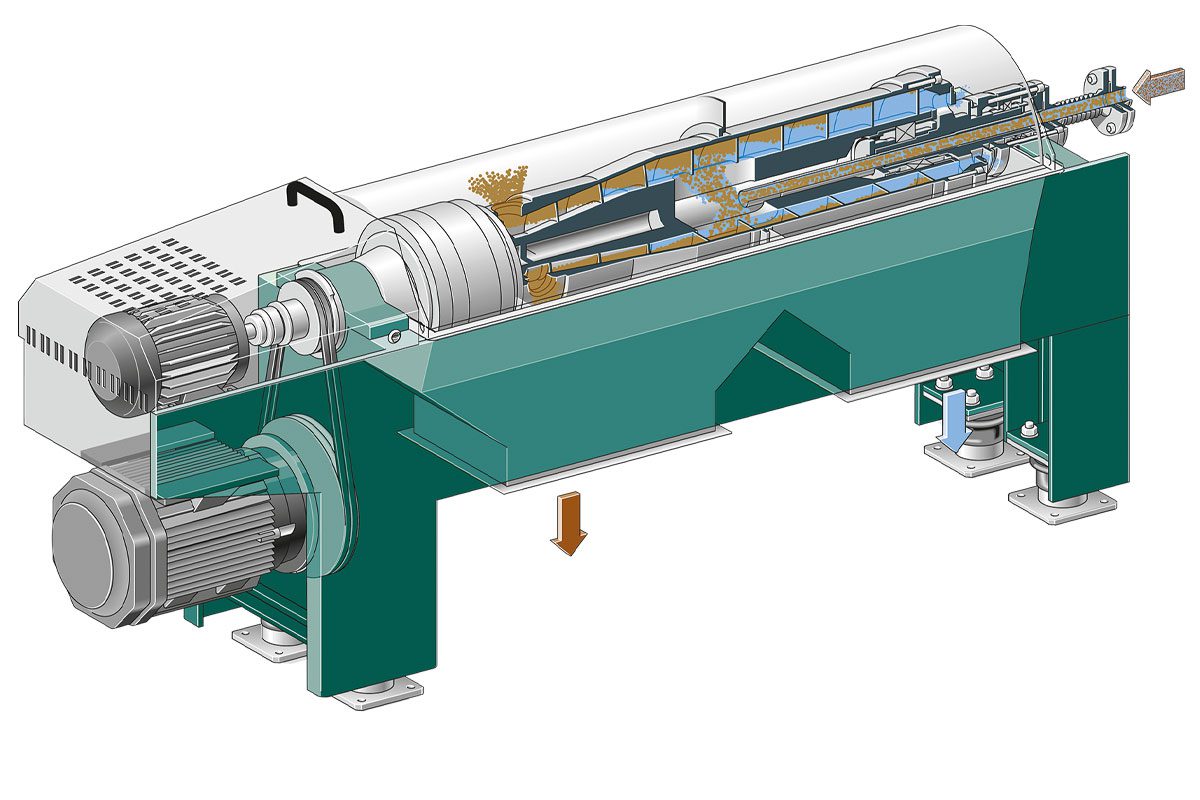

The international industrial technology group has installed its environmental sludge decanter pro line system at Biffa’s new multi-million PET plastic recycling facility in Seaham, reducing the plant’s reliance on transporting waste sludge from the process and significantly improving efficiency. Biffa also ordered the same equipment from GEA for its Washington site, which handles high-density polythene (HDPE) plastic.

In conjunction with a service plan provided for Biffa, GEA’s future-proof solution has brought clear environmental benefits, significantly cutting the plants’ carbon footprints due to fewer tankers being on the road.

Chris Clarke, GEA Business Manager – Environmental, said: “Even though still in lockdown, we were able to work quickly and safely with Biffa to arrange a trial on site. Due to the success of the trial, GEA immediately installed a hire unit until the permanent machine could be delivered. A duplicate order for the decanter for dewatering sludge was then received for the Washington plant.”

GEA’s automation expertise is making an invaluable contribution to the recycling of plastic at plants across the globe. Its sludge decanter pro line system for removing contaminants from the recycling process of PET bottles is based on decades of market-leading expertise in the field of wastewater, with which pioneering processes and technologies for sludge treatment are continuously being developed.