The Royal Mint has signed an agreement with Canadian clean tech start up Excir to introduce a seemingly world first technology to the UK, allowing it to safely retrieve and recycle gold and other precious metals from electronic waste.

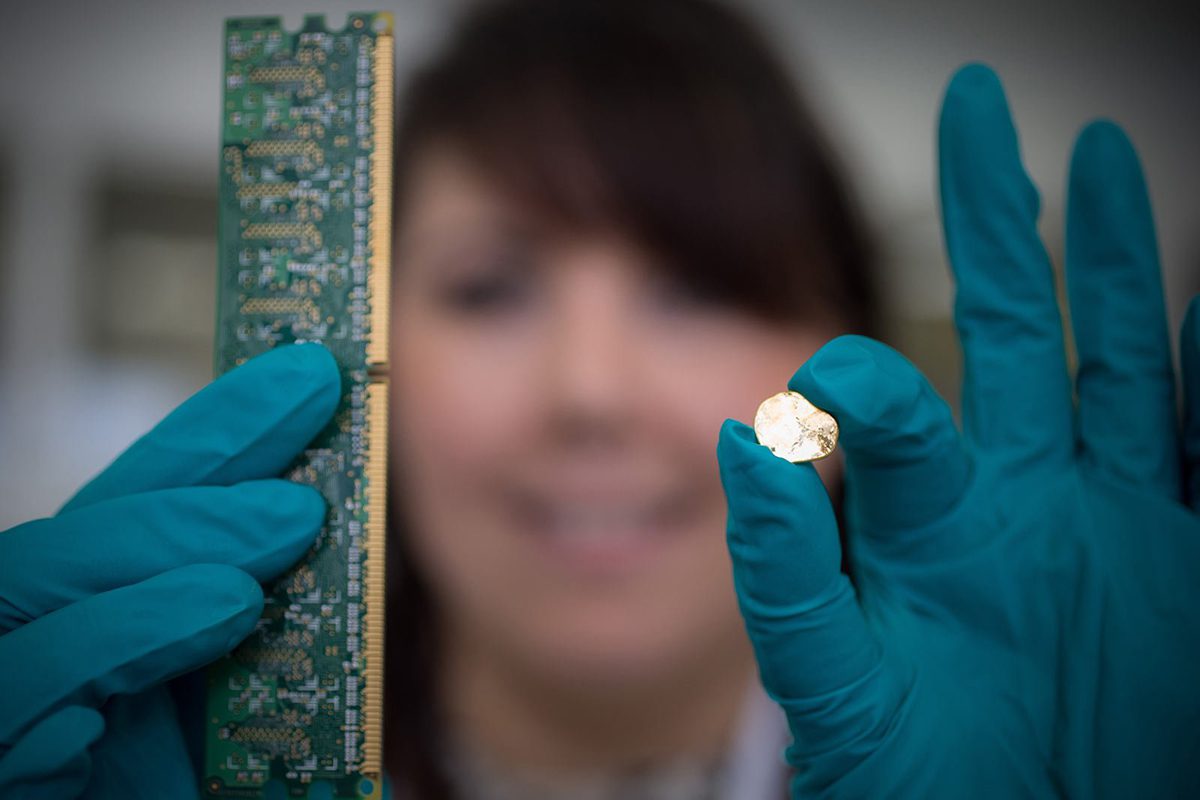

Excir’s patented technology recovers 99%+ of gold from electronic waste, contained within the circuit boards of discarded laptops and mobile phones. The chemistry selectively targets and extracts precious metals from circuit boards in seconds, says the firm – offering a new solution to the world’s fastest-growing waste stream.

Each year, more than 50 million tonnes of electronic waste is produced globally, equivalent in weight to 350 cruise ships the size of the Queen Mary 2. If nothing is done, this is set to reach 74 million tonnes by 2030 – almost a doubling of tonnage in a decade[1].

Less than 20% of electronic waste is currently recycled world-wide. This means that gold, silver, copper, palladium, and other highly valued metals conservatively valued at US $57 billion – a sum greater than the gross domestic product of most countries – are mostly discarded as opposed to being collected for treatment and reuse[2].

Scientists and engineers at The Royal Mint are now working to advance the technology from laboratory scale to mass production. Instead of electronic waste leaving UK shores to be processed at high temperatures in smelters, the approach will see precious metals recovered at room temperature at The Royal Mint’s site in South Wales. Initial use of the technology at the government-owned company – which produces coins for the UK – has already produced gold with a purity of 999.9, and when fully scaled up, the process has potential to also recover palladium, silver and copper.

Embracing the principles of a circular economy[3], The Royal Mint and Excir technology has the potential to ensure electronic waste is handled in a controlled and regulated manner – preserving natural resources for longer, helping to reduce the environmental impact of e-waste and fostering new skills and employment in the UK.

Anne Jessopp, Chief Executive, The Royal Mint, said: “The potential of this technology is huge – reducing the impact of electronic waste, preserving precious commodities, and forging new skills which help drive a circular economy.”

Jim Fox, Chief Executive Officer of Excir, said: “The team at Excir feel extremely fortunate to be working alongside The Royal Mint to scale Excir’s patented technology from laboratory to mass production over the coming years. Their 1,100 years of expertise in precious metals and innovation, coupled with a desire to foster new skills and benefit the environment, made them the ideal partner for us.”

Sean Millard, Chief Growth Officer at The Royal Mint, commented on Excir’s technology: “The chemistry is revolutionary and capable of recovering precious metals from electronic devices in seconds. It offers huge potential for The Royal Mint and the circular economy – helping to reuse our planet’s precious resources and creating new skills in the UK.”

Notes

[1] The Global E-waste Monitor 2020

https://www.itu.int/en/ITU-D/Environment/Documents/Toolbox/GEM_2020_def.pdf

[2] The Global E-waste Monitor 2020

https://www.itu.int/en/ITU-D/Environment/Documents/Toolbox/GEM_2020_def.pdf

[3] For more information on circular principles and practices see for example, here and here.