A low-cost seawater desalination device powered by solar energy was recently described by a group from Ulsan National Institute of Science and Technology (UNIST) in South Korea.

The device is said to be inexpensive and easy to construct using 3D printing. The work was published in the August 2021 edition of the journal Advanced Materials.

It was led by Professor Ji-Hyun Jang in the School of Energy and Chemical Engineering at UNIST. In the study, the research team reported a 3D-printed solar evaporator that can efficiently utilize solar energy (99%) with an evaporation rate of 1.60 kg m–2 h–1 and efficiency of 89% under 1 sun irradiation.

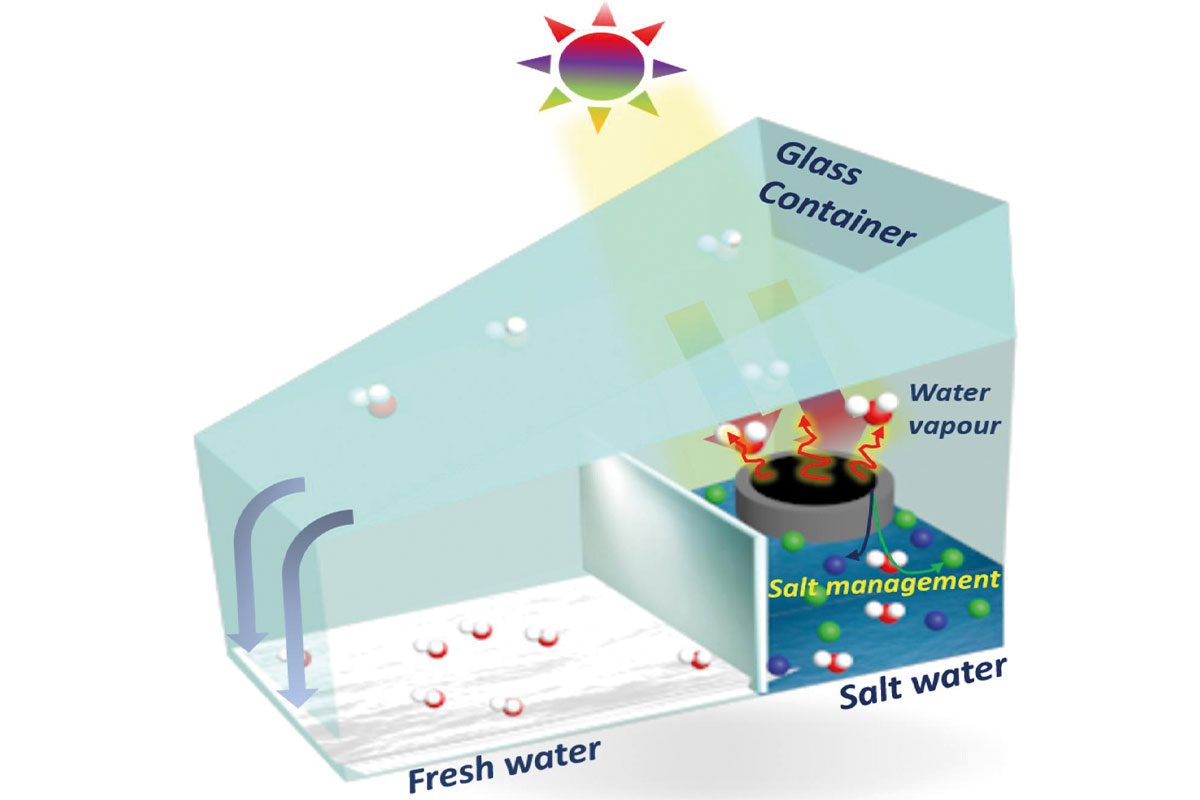

Solar-driven water evaporation uses sunlight as the sole energy source to vaporize water.

In this process, the seawater is heated until it reaches the evaporation state. The salt, however, is left behind, while the vapour is condensed to produce fresh water.

However, the solar-to-vapour efficiency has been limited due to inadequacies with the design of the evaporator, and its unability to deal with either a large amount of heat loss or salt accumulation, according to the research group.

The team seemingly addressed these issues via two cost-effective approaches: (1) The design of a concave-shaped support structure by 3D-printing that can promote the light harvesting capacity via multiple reflections on the surface; 2) The use of a double-layered photoabsorber composed of a hydrophilic bottom layer of a polydopamine (PDA) coated glass fibre (GF/C) and a hydrophobic upper layer of a carbonized poly(vinyl alcohol)/polyvinylpyrrolidone (PVA/PVP) hydrogel on the support structure, which provides improvements in preventing the deposition of salt while quickly pumping the water.