AUMA has supplied more than 150 electric actuators to Singapore’s new Keppel Marina East Desalination Plant (KMEDP), an award-winning plant that was selected as ‘Desalination Plant of the Year’ at the Global Water Awards 2021.

KMEDP is Singapore’s first large-scale, dual-mode desalination plant, designed to treat both seawater and rainwater. Due to frequent dry spells and limited land area to catch and store the rainwater, desalination is increasingly important to the island state. KMEDP gives Singapore an important weather-independent water supply, with a capacity of 137,000 cubic metres (36 million gallons) per day.

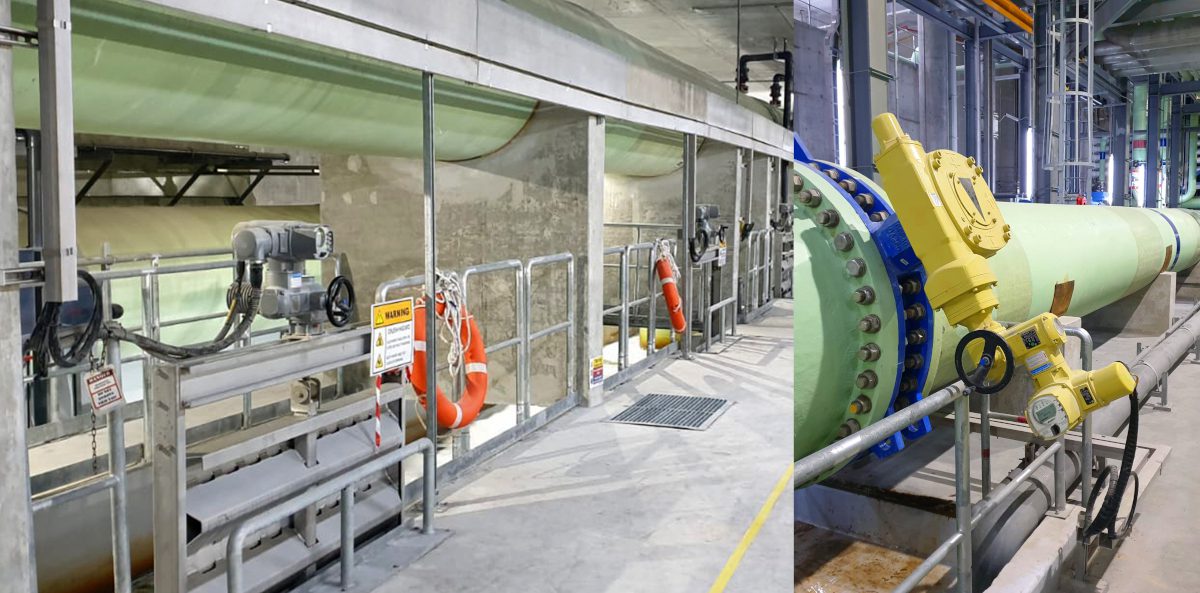

The award-winning plant uses state-of-the-art technologies to increase its energy efficiency and reduce its environmental impact. The plant’s 20,000 square metre green rooftop provides a park and recreational area. The treatment facilities and pumping station are located underground.

A total of 156 AUMA SA multi-turn and SQ part-turn actuators with intelligent AC 01.2 actuator controls have been installed throughout the different treatment steps of the desalination plant.

At the design stage, PUB, Singapore’s national water authority, was concerned that a large number of actuators would be installed in hard-to-access areas. AUMA, which had already cooperated with PUB on numerous projects in the past, put forward the benefits of its actuators’ modular design. The ability to mount the actuator controls separately from the actuator if necessary, and to orient the display to suit different mounting positions, perfectly met PUB’s requirements.

After sales services with timely on-site support whenever needed was also a critical factor for Keppel Infrastructure, which has a 25-year Design, Build, Own and Operate (DBOO) concession for the plant.

“The AUMA service team is also supporting another business unit of Keppel for the Senoko Waste to Energy Plant, where AUMA Singapore has a servicing and maintenance contract,” says Stefan Kolbe, Sales Director Southeast Asia at AUMA. “Our track record of timely support and technical know-how convinced Keppel that they can depend on us for any issues.”