A new system appears to allow more energy to be gotten from biomass (such as forest and agricultural waste) with the help of a chemical reactor that can work from solar power.

Biological waste contains a large amount of energy, if used properly. It’s often available in the form of plant and other vegetable remains, as well as animal or household waste – all of it coming under the catch-all term “biomass”.

These bio-residues are characterised by high humidity, which requires a drying pre-treatment process before they are processed using conventional thermal technologies such as pyrolysis, gasification, or dry torrefaction.

“This is not an economic option, as a significant amount of energy is used for the drying pre-treatment,” explains Jesús Gómez Hernández of the Universidad Carlos III de Madrid (UC3M), and author of a recent paper proposing a novel new approach to exploiting the energy potential of biomass.

“In order to solve this, hydrothermal biomass carbonisation (HTC) could be an interesting technology that could be used to process this waste, as the drying pre-treatment is not needed.”

Using HTC with solar power

The paper – appearing in the scientific journal Renewable Energy – details how HTC can be used in conjunction with a solar power facility to make the process more sustainable and extract energy from pine residues, corn stover, or rice husks, for example.

“The products obtained could be applied to energy production processes, the improvement of soil substrates, supercapacitors, and bio-refineries to create a fossil-fuel-free economy, opening a technological path toward a circular economy,” say the authors.

The reactor

The HTC comprises a thermochemical treatment, whereby the biomass is processed in a reactor with hot water (at between 180 and 250ºC) at a high pressure (from 10 to 40 bar) to obtain a high value-added product: hydrocarbon. “In other words, the natural process for the formation of coal from biomass is reproduced under laboratory conditions,” says Hernández.

The main drawback is that HTC requires a lot of energy. But help seems to be at hand in the shape of another renewable energy source: solar energy.

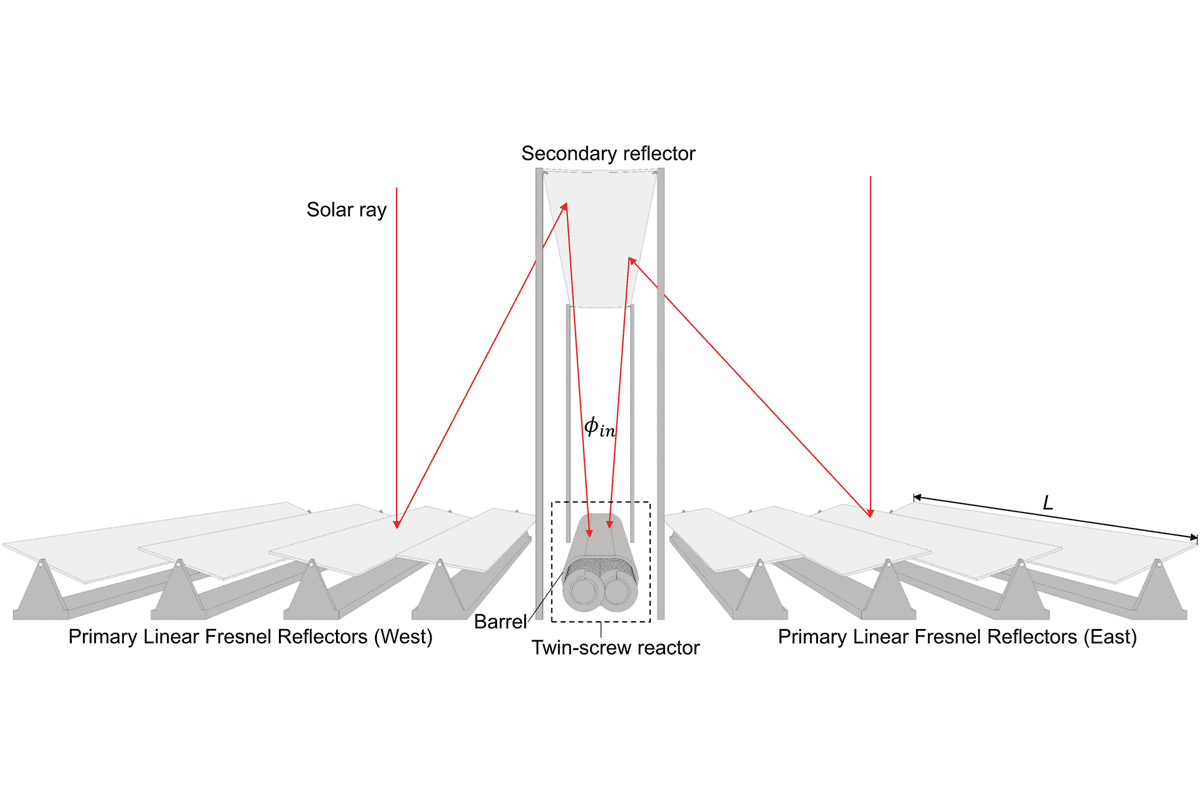

“Our work analytically models an HTC process for twin-screw reactors coupled to a linear beam-down solar field (LBD) in order to be sustainable in terms of energy,” say the researchers. The system would operate roughly as follows: two sets of reflective mirrors redirect the solar rays to another secondary mirror that concentrates all the solar energy on the screw reactor, which is installed on the floor due to its weight. They have found that this could extract energy in a renewable and sustainable way from different lignocellulosic biomasses, the most abundant raw material for biofuel production available on Earth.

Commercial processes

As the paper explains, several companies have developed commercial HTC reactors. For example, AVA has built an HTC demonstration plant with several reactors working in parallel as a multi-batch system. Another firm, TerraNova Energy, has come up with a continuous stirred-tank reactor that employs a heat exchanger to heat the biomass – and this is being used to process sewage sludge. Artec used a tubular reactor for continuous HTC. A tube arrangement of 3000 l is proposed for use in small villages or large farms to reduce biomass transport. Ingelia’s HTC pilot plant can process continuously 1200–2400 kg of biomass per day. This facility needed a thermal energy of 3600–4900 MJ/kg for heating a vertical pressurized cylinder up to the HTC reaction’s temperature when processing lignocellulosic biomass waste feedstocks (organic fraction of municipal solid waste, orange peel waste and residues of a pepper plantation). Such energy represented 25–35% of the inherent energy of the obtained hydrochar. A different approach is proposed by Hoekman et al, whereby a modified twin-screw extruder (TSE) was used to experimentally study a fast HTC process of loblolly pine. The results showed that a TSE can produce hydrochar in higher yields than when using batch HTC processes for similar reaction conditions. In fact, say the authors, TSEs are widely applied in industry as this ensures consistent product performance, there is a good control of the raw material feed and the temperature of each screw element can be monitored.