Metal recycler EMR says it is taking the next step in its efforts to create a sustainable, circular supply chain for rare earth magnets.

Powerful neodymium (NdFeB) magnets are an essential material in a range of modern technologies, from electronic motors and audio speakers to the electric drive units (EDUs) that power the latest electric vehicles. Extracting the raw materials for NdFeB magnets from the ground is both carbon intensive and has a negative impact on biodiversity.

The Secure Critical Rare Earth Magnets for the UK (SCREAM) project brings together a consortium that includes EMR, Jaguar Land Rover, GKN Automotive, Mkango Rare Earths UK Ltd, HyProMag, Bowers & Wilkins and the University of Birmingham.

EMR is investing £383,000 in the three-year project to create a proof of concept. This will be match-funded by the UK government via UK Research and Innovation (UKRI).

In addition to enabling EMR to analyse liberation and processing time, and to identify the most efficient sources of NdFeB magnets among recycled materials, SCREAM will also help understand the future market potential of recycled NdFeB magnets, with a view to creating a fully commercial circular supply chain in the future.

EMR’s partner GKN Automotive Innovation Centre will re-engineer a state of the art 800v production emachine and build it with specified recycled magnets created by the consortium. In addition, GKN Automotive will test the new motor and magnet performance to verify their performance and capability relative to virgin material and the original machine.

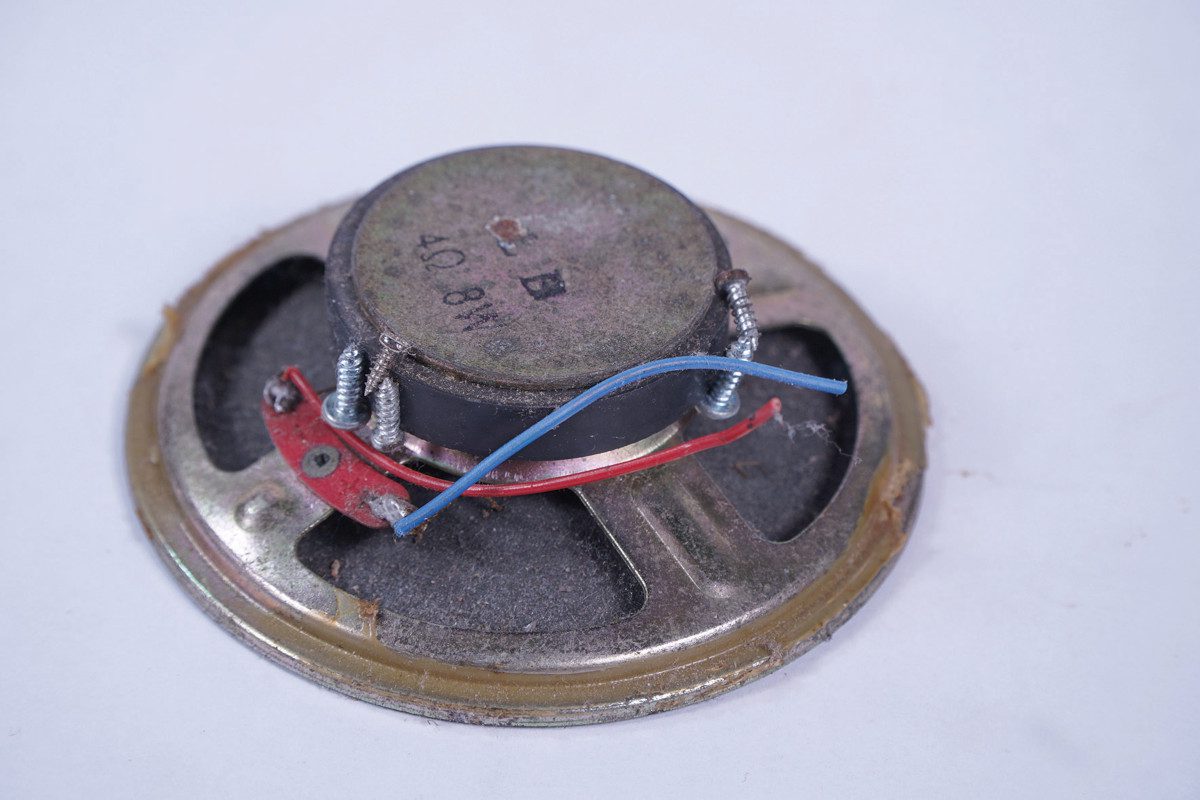

SCREAM builds on an earlier successful project called REAP (Rare-Earth Extraction from Audio products) project and utilises Hydrogen Processing of Magnet Scrap (HPMS) technology developed by HyProMag.

EMR says it will supply high-quality, recycled NdFeB magnets from its waste stream, using processes including state-of-the-art robotic separation technology to extract material from TV speakers, washing machines and end-of-life vehicles. This valuable material would traditionally have been processed with ferrous metals and lost to the supply chain. The SCREAM project highlights how EMR is using innovation and new technology to further increase the sustainability of the metal recycling industry.

Dr Joseph Eke, Engineering Research and Development Manager at EMR, said: “SCREAM is the next exciting chapter in EMR’s efforts to create a sustainable and circular supply chain for rare-earth magnets. This is valuable material which has previously been lost during the recycling process, but, thanks to the innovation and insights we have developed in recent years, we’re now closer than ever to ensuring NdFeB magnets are recycled, processed and re-used for the next generation of applications.

“Whether its mining conflict areas such as the Democratic Republic of Congo (DRC) – for cobalt – or politically sensitive places such as Russia – for nickel – many rare-earth materials are found in parts of the world where the UK doesn’t have control over their source. As electric vehicles are rolled out in greater numbers, the amount of NdFeB magnets available in the waste stream will increase significantly, so it’s now a race against time to ensure that the industry is able to recover this material efficiently and sustainably.

“By working together with the rest of the SCREAM consortium, EMR is ensuring that, in the future, there is a stable and sustainable source for these materials that manufacturers and consumers can rely on.”