A magnetic field can help enhance the generation of synthetic biogas, according to new research.

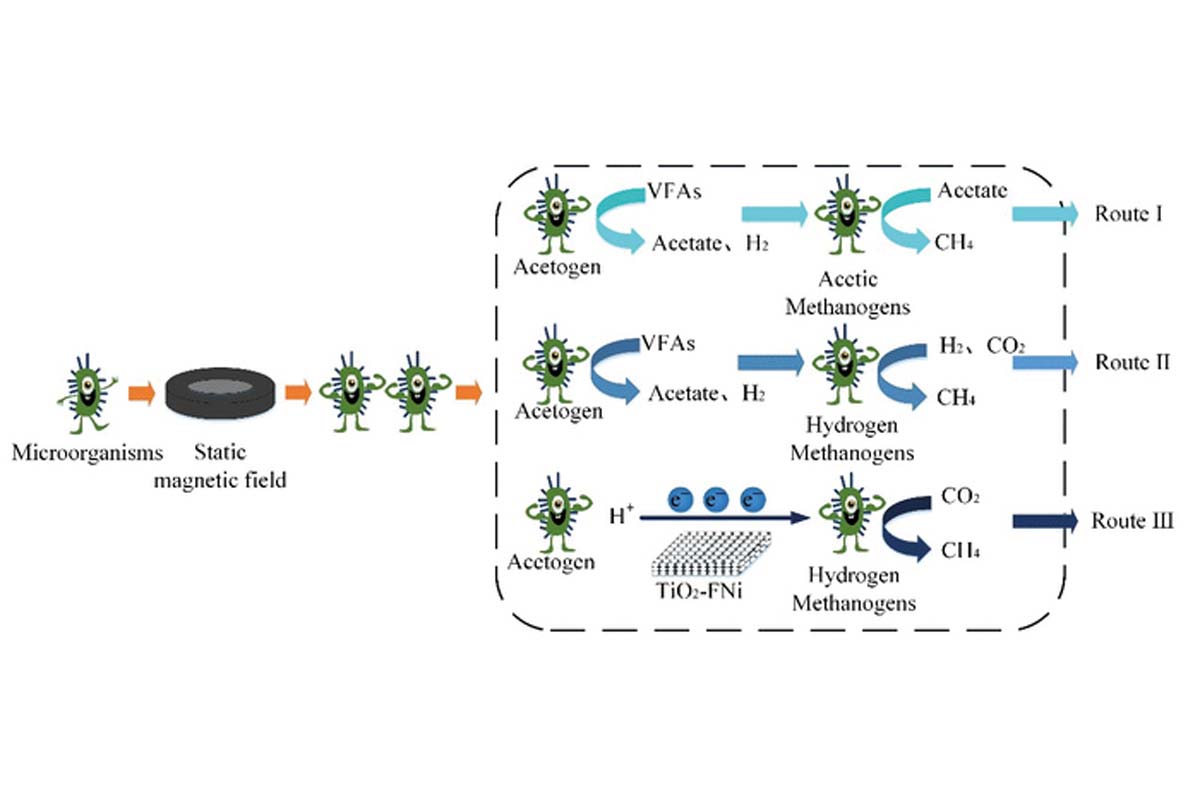

The researchers investigated the effects of a static magnetic field (SMF) in the presence of the additive titanium dioxide-foamed nickel (TiO2-FNi). It exhibits bioaffinity for the relevant methanogens during the anaerobic digestion and methanation of corn stover (which comprises the leaves, stalks, and cobs of corn). In this process, TiO2-FNi is deposited on the bottom of the reactor in bulk form and the external magnetic field environment is provided by permanent magnets.

It was carried out by a research team from the Shenzhen Institute of Advanced Technology (SIAT) of the Chinese Academy of Sciences (CAS). The study was published in Energy.

The additive TiO2-FNi is a porous conductive material, with a multi-grooved surface, and combined with the non-biotoxicity of TiO2, provides a favourable surface for the adhesion of flora and the formation of electroactive biofilms that promote electron transfer.

The intensity of the magnetic field is regulated by controlling the distance between the permanent magnet and the bottom of the reactor.

With the recovery rate of TiO2-FNi composite material reaching 99.29%, the process showed good recovery potential and environmental friendliness, said the group. The energy balance analysis also showed that the anaerobic fermentation process in the experimental group was 43.68%, which was 13.20 percentage points higher than the control group.

The experimental results showed that methane production increased 44.71% at a 2.82g L-1 TiO2-FNi concentration and with a 11.4mT magnetic field. “By strengthening the methane production path of direct interspecies electron transfer, the recycling of CO2 is realized and the carbon emission in the reaction process is reduced,” said author Dr Zhang Yanhui.

He said the study demonstrates an environmentally friendly and sustainable strategy for the large-scale production of methane and hydrogen from agricultural waste.