The desire for speed of supply in the water and power utilities sectors can often mean that actuator specifications are repeated, based on a like-for-like replacement. Likewise, many specifiers may be unaware of design advances and innovations that, if known, would influence product selection, as component manufacturer AUMA Actuators explains.

Colin Borrows is Operations Manager at AUMA Actuators Limited. He explains: “At AUMA we focus on what our customers need, not what they want. We prefer to think of ourselves as solutions consultants, rather than product suppliers. We use our inherent knowledge and expertise to understand better the environment and operating conditions for which a particular product has been selected.

“Once equipped with that knowledge, our engineers are better placed to offer advice on solutions that may offer increased value returns, or enhanced performance characteristics. A recent example of how we apply lateral thinking to the needs of our customers is an approach that we received for a vandal proof actuator.

“Firstly, we asked our customer to clarify what exceptional circumstances meant that they needed a ‘vandal proof’ solution. Once we understood that the actuator was in a frequently accessed location and often subjected to damage, we dug a little deeper to build a better picture of the site. Our logical solution was to install one of our specialist underwater actuators in an existing underground concrete chamber. This meant that the actuator was out of sight and only accessible to maintenance personnel.”

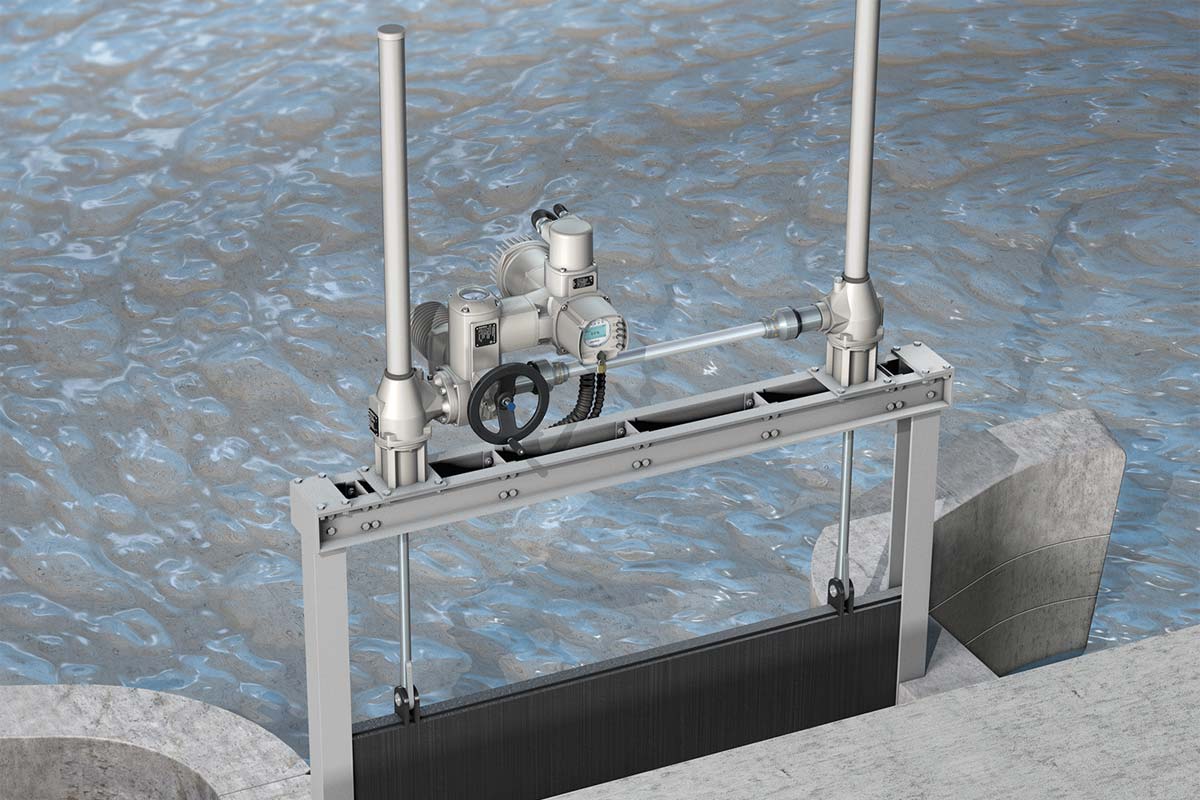

Actuators and valves are often installed in chambers below ground level when both water supply and sewer pipes are underground. The AUMA SA multi-turn actuator for continuous underwater use opens new applications for electric actuators: for water supply, in hydropower plants, in civil engineering constructions for water applications, and for specific underwater applications.

Where high water levels are a permanent risk, actuators designed for underwater use operate reliably even if flooding persists, incorporating a universal sealing system, combined with comprehensive corrosion protection. Double-sealed cable glands at the electrical connection, inner seals – some in pairs – on all housing covers, and a one-piece solid shaft prevent the ingress of water.

Colin Borrows continues: “AUMA electric actuators are not only easy to install – just requiring a power source and a signal cable – but they are also characterised by low operating costs and are virtually maintenance-free. AUMA actuators are also environmentally friendly, as no oil is used that might leak and contaminate the water. This turns them into a real alternative to hydraulics.”

AUMA’s SA and SAR actuator types, as well as the new variable-speed SAV and SARV versions, are available for continuous underwater use in sizes 07.2 to 16.2. As standard, the actuators are qualified for up to 15m head of water, with higher heads of water are available on request.

All actuator settings including end position setting for travel and torque are non-intrusive via the AC actuator controls, with no need to open the actuator housing. The actuator controls are installed outside the flooded area, separate from the valve and actuator. Cable lengths up to 100 m can be achieved.

AUMA has also enhanced its underwater actuators with explosion-proof versions. These actuators are suitable for continuous immersion, considerably extending the scope of application of electric actuators in water supply systems, hydropower plants, civil engineering constructions for water applications, and specific underwater applications.

SA and SAEx actuators in sizes 07.2 to 16.2 for continuous underwater use are qualified for up to 15 m head of water, with higher heads of water available on request. Explosion-proof versions meet ATEX requirements.

Colin concludes: “Understanding what a customer wishes to achieve is core to being able to advise appropriately. Five minutes invested in a conversation on receipt of an enquiry can result in considerable cost savings and operating efficiencies. That’s the AUMA way – focusing on what you need, not what you want.”