Combining synthetic biology with materials innovation, a bioelectronic sensor demonstrates the possibilities of using specially engineered bacteria to provide real-time sensing of chemical pollutants. Importantly, the microbes within the device are encapsulated to avoid their release.

The study, published in Nature in November, purports to show that cells can be ‘programmed’ to identify different chemicals, stimulating a measurable electrical current.

Such “smart” devices could power themselves by scavenging energy in the environment as they monitor conditions in settings like rivers, farms, industry and wastewater plants.

The environmental information communicated by these self-replicating bacteria can be customized by replacing a single protein in the eight-component, synthetic electron transport chain that gives rise to the sensor signal.

“I think it’s the most complex protein pathway for real-time signaling that has been built to date,” said Jonathan Silberg, director of Systems, Synthetic and Physical Biology at Rice University. “To put it simply, imagine a wire that directs electrons to flow from a cellular chemical to an electrode, but we’ve broken the wire in the middle. When the target molecule hits, it reconnects and electrifies the full pathway.”

“It’s literally a miniature electrical switch,” said Caroline Ajo-Franklin, also lead author.

“You put the probes into the water and measure the current,” she said. “It’s that simple.

Our devices are different because the microbes are encapsulated. We’re not releasing them into the environment.”

The researchers’ proof-of-concept bacteria was Escherichia coli, and their first target was thiosulfate, a dichlorination agent used in water treatment that can cause algae blooms.

And there were convenient sources of water to test: Galveston Beach and Houston’s Brays and Buffalo bayous.

They collected water from each. At first, they attached their E. coli to electrodes, but the microbes refused to stay put. “They don’t naturally stick to an electrode,” Ajo-Franklin said.

“We’re using strains that don’t form biofilms, so when we added water, they’d fall off.”

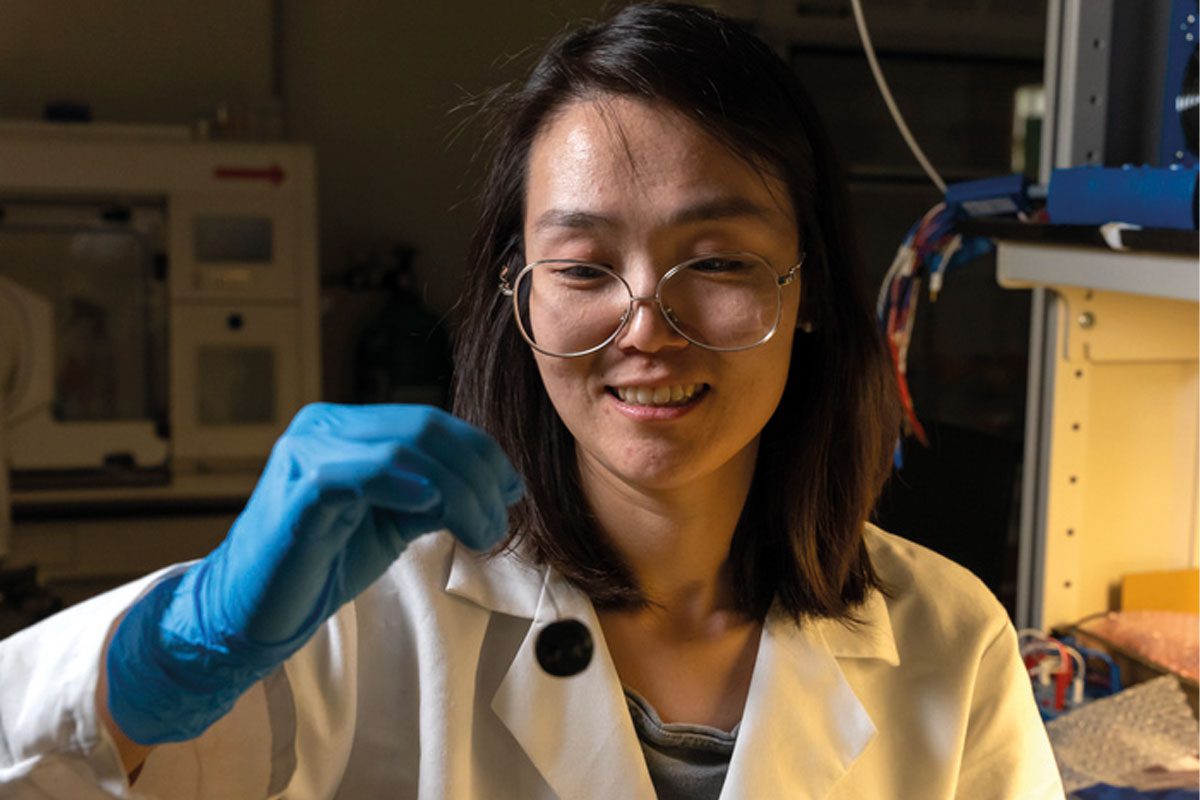

When that happened, the electrodes delivered more noise than signal. Enlisting co-author Xu Zhang, a postdoctoral researcher in Ajo-Franklin’s lab, they encapsulated sensors into agarosein the shape of a lollipop that allowed contaminants in but held the sensors in place, reducing the noise.

“Xu’s background is in environmental engineering,” Ajo-Franklin said. “She didn’t come in and say, ‘Oh, we have to fix the biology.’ She said, ‘What can we do with the materials?’ It took great, innovative work on the materials side to make the synthetic biology shine.”

With the physical constraints in place, the labs first encoded E. coli to express a synthetic pathway that only generates current when it encounters thiosulfate. This living sensor was able to sense this chemical at levels less than 0.25 millimoles per litre, far lower than levels toxic to fish.

In another experiment, E. coli was recoded to sense an endocrine disruptor. This also worked well, and the signals were greatly enhanced when conductive nanoparticles custom-synthesized by Xu were encapsulated with the cells in the agarose lollipop. The researchers reported that these encapsulated sensors detect this contaminant up to 10 times faster than the previous state-of-the-art devices.

The study began by chance when Atkinson and Moshe Baruch of Ajo-Franklin’s group at Berkeley Lawrence National Laboratory set up next to each other at a 2015 synthetic biology conference in Chicago, with posters they quickly realized outlined different aspects of the same idea.

“We had neighboring posters because of our last names,” said Atkinson. “We spent most of the poster session chatting about each other’s projects and how there were clear synergies in our interests in interfacing cells with electrodes and electrons as an information carrier.”

“Josh’s poster had our first module: how to take chemical information and turn it into biochemical information,” Ajo-Franklin recalled. “Moshe had the third module: How to take biochemical information and turn it into an electrical signal.

“The catch was how to link these together,” she said. “The biochemical signals were a little different.”

The collaboration brought Ajo-Franklin to Rice in 2019. She said the project was “incredibly synergistic” between Lin and Josh. “They would bounce ideas back and forth and through that interchange solved a lot of problems.”

Silberg said the design’s complexity goes far beyond the signaling pathway. “The chain has eight components that control electron flow, but there are other components that build the wires that go into the molecules,” he said. “There are a dozen-and-a-half components with almost 30 metal or organic cofactors. This thing’s massive compared to something like our mitochondrial respiratory chains.”

Silberg said he sees engineered microbes performing many tasks in the future, from monitoring the gut microbiome to sensing contaminants like viruses, improving upon the strategy of testing wastewater plants for SARS-CoV-19 during the pandemic.

“Real-time monitoring becomes pretty important with those transient pulses,” he said. “And because we grow these sensors, they’re potentially pretty cheap to make.”