Digital building modelling has reduced energy consumption by almost a third at two Jaguar Land Rover facilities, according to Glasgow based IES Consulting, a built environment specialist.

IES Consulting was commissioned by Penston MEP (M&E Consultants) to carry out integrated building performance modelling at the two facilities at the vehicle manufacturer’s Software Engineering Centre in Shannon, Republic of Ireland.

This location is branded as Jaguar Land Rover’s hub for autonomous and next generation vehicle projects. The centre will develop new technologies to support electrification and self-driving features on future Jaguar and Land Rover vehicles.

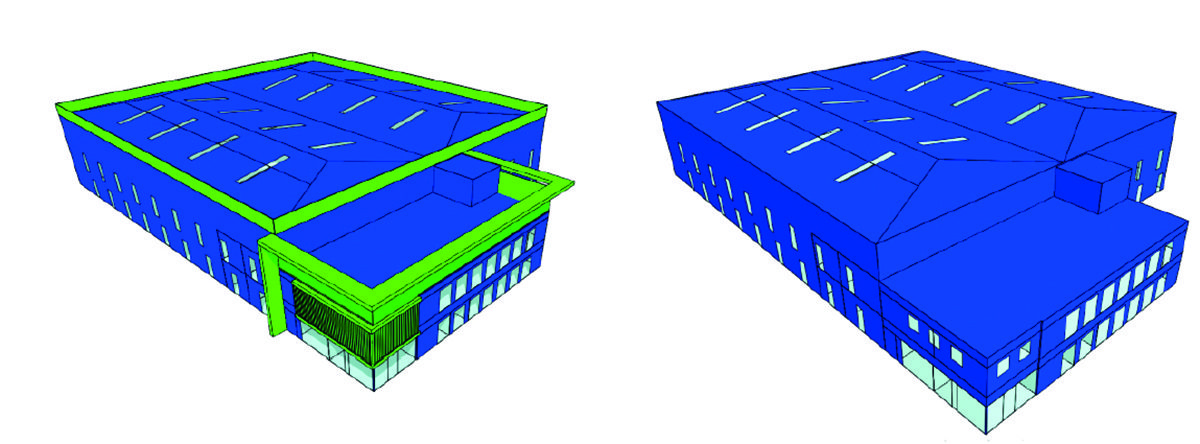

IES Consultants used its proprietary virtual environment (or IESVE) software to analyse the performance of a four-storey office development and a 3,100m2 warehouse and lab facility situated at the centre. Both projects were pursuing certification via LEED v4 Interior Design and Construction – Commercial Interiors.

Office development

This four-storey development consists of a total occupied floor area of 4105m2 and includes office space, meeting rooms lounge areas and lab areas.

The group used IESVE to apply the building performance rating method (BPRM), and in this way were able to determine the proposed energy consumption for the office development and compare it against the ASHRAE 90.1 2010 baseline model. This included assessing and applying a number of energy efficiency measures (EEMs) to the model, and analysing various options to ensure a high-performance building envelope. In doing this, IES consultants said they were able to achieve a total energy cost saving of 24.5% over the ASHRAE 90.1 2010 baseline model. This saving meets the minimum 3% LEED EAp2 prerequisite and also achieves 24 LEED EAc1 points, which led to the building achieving a LEED Gold certification.

The primary HVAC system for the new building consists of two roof-mounted OAHUs feeding the restrooms and kitchen. The tenant areas are served by zone level FCU’s with outdoor air supplied by zone level heat recovery units. Hot water is supplied by two high efficiency natural draft boilers each with a heating capacity of 327kW. Chilled water for the FCU cooling coils is supplied by two air cooled scroll chillers each with cooling capacity of 308kW. Chilled water is circulated via a number of VSD secondary pumps and CV primary pumps.

Additional energy efficiency measures implemented are as follows:

• High efficiency interior lighting design in tenant areas <8W/m2

• OAHU energy recovery + HRU units (up to 90% energy recovery effectiveness)

• High efficiency condensing boilers (89% efficiency)

• High efficiency FCU units with EC fan motors (0.26W/l/s on average)

• High efficiency scroll chillers COP 4.13 @ design conditions

• VSD secondary chilled water pumps

• VSD secondary HW pumps

• Warehouse and Lab Facility

This facility is used for the testing and analysis of Jaguar’s electric and automated driving vehicles in support of electrification and self-driving elements on future Jaguar and Land Rover vehicles. The warehouse/testing facility takes up the majority of the building floor area at 2,300 m2. The remaining floor area is comprised of offices/research labs, meeting rooms, restrooms and a staff kitchen.

Using the same modelling process as outlined above, IES consultants were able to demonstrate that implementing a combination of energy efficiency measures along with a high-performance building envelope would lead to a total energy cost saving of 28.9% for the building. This facility also achieved LEED Gold certification.

The building has been designed for high energy efficiency by employing a number of low energy design strategies. The warehouse is heated via high efficiency gas-fired, air heaters with axial fans that operate in parallel with de-stratification fans that significantly improve the heat distribution effectiveness. It is ventilated via a mixed mode mechanical ventilation system comprised of exhaust fans with variable speed drives and low-level intake louvers that include motorised dampers linked to air quality sensors. The system automatically adjusts outside airflow to ensure adequate ventilation is provided at all times. Occupants also have access to operable windows for local comfort.

The office area is conditioned by a high efficiency Variable Refrigerant Flow (VRF) air conditioning system. Outside air is provided by an air handling unit with high efficiency energy recovery. LED lighting is provided throughout the building. Lighting control is provided by the “Enlighted” lighting control system that incorporates both PIR occupancy sensing and digital ambient light sensors for daylight harvesting. A photovoltaic system comprised of 18m2 of monocrystalline modules contributes in reducing the buildings energy costs by over 1%.

Adam Goves, Sector Lead – Manufacturing & Infrastructure at IES, said: “Jaguar Land Rover’s facilities are developing cutting-edge vehicle technology, and it’s only fitting that its warehouse, lab and office spaces are now benefiting from the latest building modelling technology too. Often Net Zero strategies for manufacturers are focused on the supply chain and operations, and whilst this is an important step, it’s vital not to overlook the impact that enhancing the performance of the buildings can have.”