A recycling site in Sweden will process 125,000 tons of end-of-life batteries and battery production waste each year, making it the largest plant of its kind in the world, according to Swedish battery developer Northvolt, which is working with industrial technology firm ABB on the project.

Since 2017, ABB has delivered electrification and automation equipment to power Northvolt’s Ett gigafactory for lithium-ion batteries in Sweden. The partnership is now being expanded to include battery recycling with ABB providing process electrification to power the Revolt Ett facility, being established by Northvolt in Skellefteå, northern Sweden. The plans were made in the first quarter of 2023, with financial details undisclosed.

Revolt Ett will ultimately process 125,000 tons of end-of-life batteries and battery production waste each year. It will service Northvolt’s gigafactory on the same site, which brought one production block online in 2022 and will establish others to reach an annual production capacity of 60 GWh.

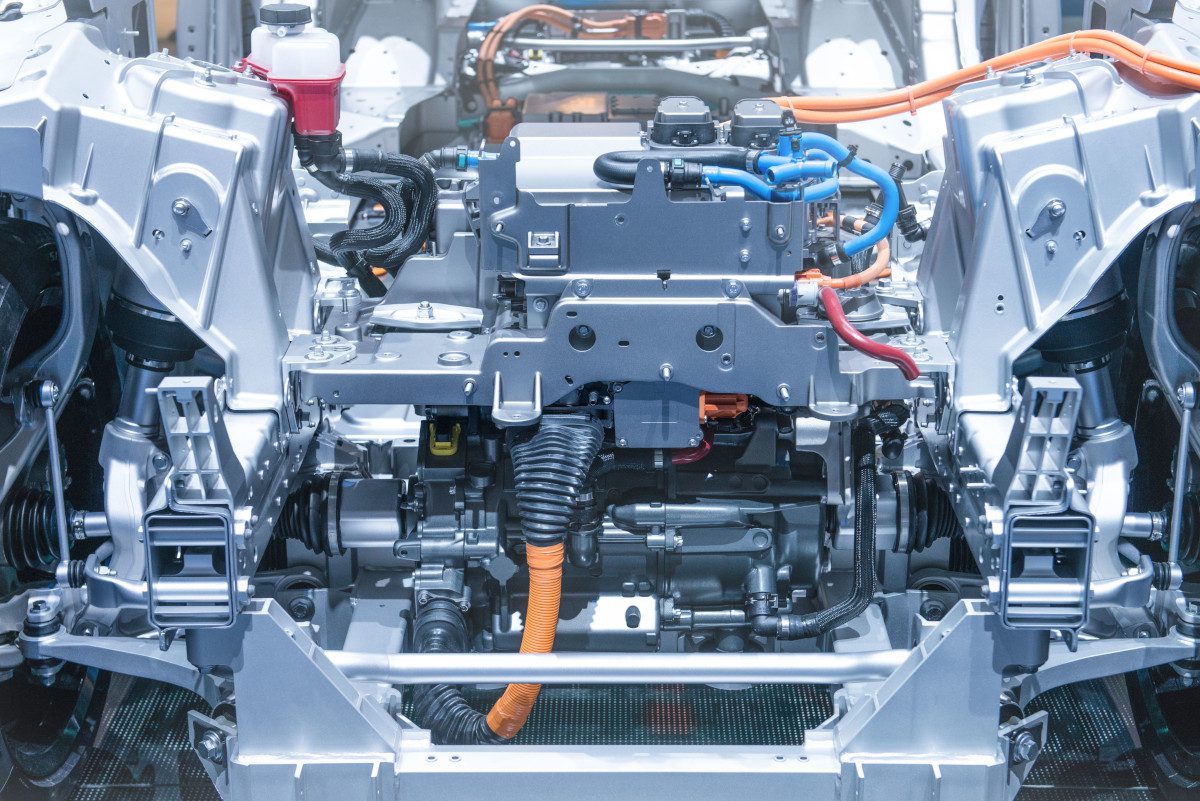

Northvolt supplies a range of lithium-ion batteries to the automotive, industrial, and large-scale energy storage sectors that support the global energy transition. The producer aligns with World Economic Forum figures which project a demand for batteries that will increase 14-fold by 2030 due to the adoption of electric vehicles.

“ABB will deliver switchgears and variable speed drives to the facility, which will match the speed of the processes taking place in the factory, ramping power up and down as required, saving energy, improving performance and lowering maintenance.”

The facility will start operations in 2023. The company plans to reduce the carbon footprint of its batteries to 10 kg CO₂e per kilowatt hour (kWh) by 2030, compared to an industry reference of 98 kg CO₂e per kilowatt hour (kWh). Key to achieving this target, Northvolt Ett is powered by 100 percent fossil-free energy.

As increasing numbers of batteries in the market reach end of life, recycling via Revolt Ett’s battery materials recovery and hydrometallurgical (hydromet) processes is set to supply up to 50 percent of Northvolt Ett’s raw material needs for lithium, nickel, cobalt and manganese by 2030, says the company. By that point in time, Northvolt aims to have the capacity to manufacture 150 GWh per annum across its operations in Sweden and Germany.