A seemingly groundbreaking technology – an Automated Seagrass Planter (ASP) – holds forth the promise of being able to subtantially scale-up this kind of restoration activity, says engineering firm Land & Water.

The design, construction, and testing of the new vehicle was undertaken by the firm working in conjunction with marine conservation group Project Seagrass. Land & Water says it promises to revolutionise the large-scale planting of seagrass, offering new hope for the restoration and preservation of these vital coastal ecosystems. “We are now convinced we can substantially scale up seagrass glade restoration using the automated planter, taking conventional planting (done with divers on an individual seedling basis) to sea-scape scale planting at 1000’s of plants per day,” says James Maclean, CEO of Land & Water.

Seagrass meadows play a crucial role in maintaining healthy marine environments, fostering biodiversity, and mitigating climate change by capturing carbon dioxide from the atmosphere. Globally, seagrass has the capability to capture carbon faster than tropical rainforests, accounting for 10 to 18% of total ocean carbon storage, despite covering less than 0.1% of the seafloor [source: Duarte et al., 2005b; Kennedy et al., 2010]. However, due to various human activities and natural disturbances, seagrass habitats have been rapidly declining worldwide. In the UK alone seagrass depletion since 1936 EXCEEDS 30% of the areas of previous colonisation.

Recognizing the urgency to restore these critical ecosystems, Land & Water partnered with Project Seagrass and Swansea University to develop what they describe as a cutting-edge solution. The Automated Seagrass Planter “represents a significant breakthrough in seagrass restoration efforts, aligning the use of biodegradable seedpods/hessian sacks developed by Project Seagrass with the installation innovation from Land & Water”.

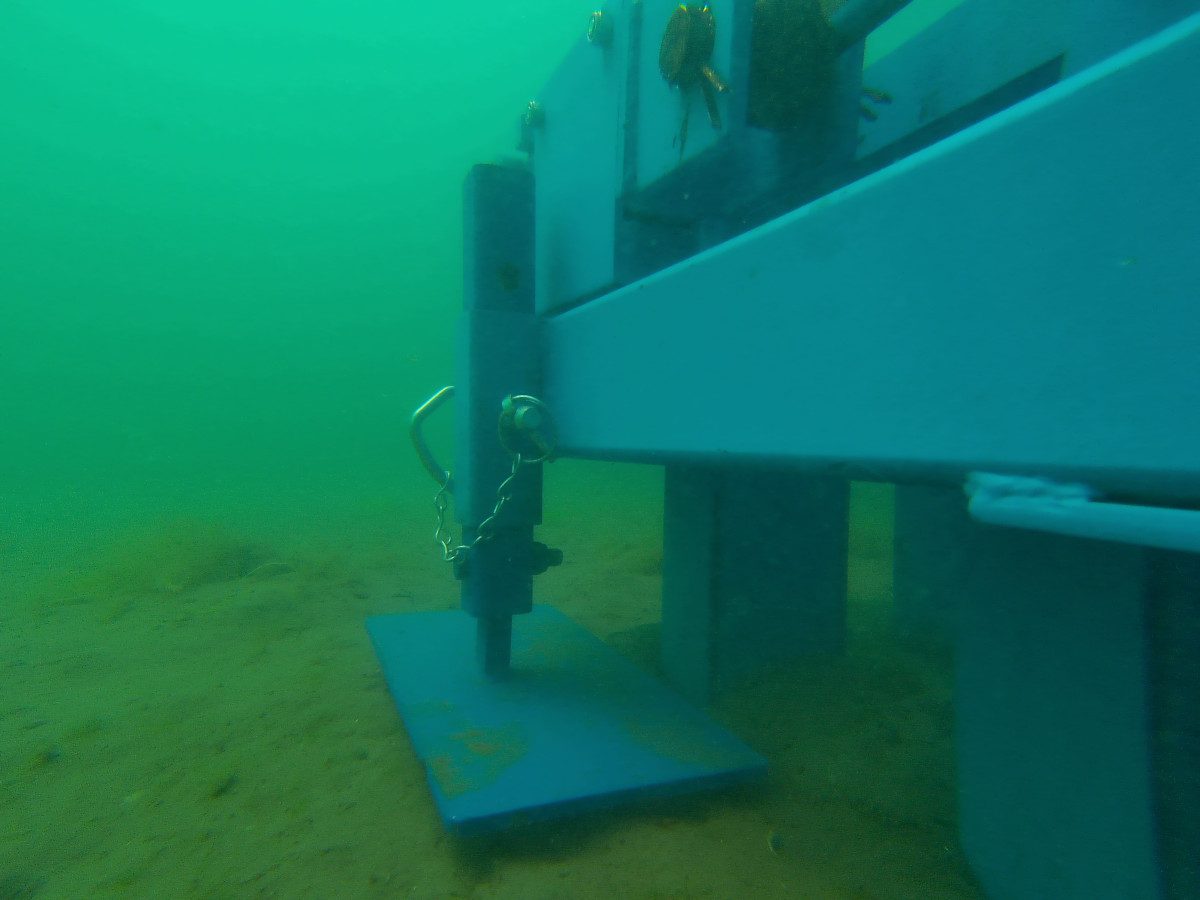

Land & Water cites a number of benefits accruing from the design of the new vehicle including the opportunities it presents to conduct precision planting. “The ASP employs advanced technology to accurately place hessian sacks filled with sand and seeds in pre-assessed locations, ensuring optimal growth conditions and maximizing survival rates.”

It can also work in subtidal and intertidal areas in water depths of up to 6metres. And claims are made for its efficiency too: “The automated system significantly reduces the time and effort required for manual planting, enabling the execution of large-scale projects in a cost-effective and timely manner.”

The firm also says that the ASP is designed to minimise environmental impact during the planting process. “It ensures optimal spacing of seagrass plugs, reducing competition for resources and promoting healthy growth and global positioning technology to record the mosaic of juvenile habitats planted.”

The ASP can be adjusted to accommodate various seagrass species and local conditions, meeting the needs of restoration projects in diverse coastal environments.

The successful testing of the Automated Seagrass Planter has yielded promising planting results, demonstrating its effectiveness in enhancing seagrass restoration efforts. By enabling the rapid planting of seagrass at scale, this technology has the potential to rejuvenate degraded habitats, enhance coastal resilience, promote marine biodiversity, and provide substantial new habitats for carbon sequestration.

Trial planting regimes will be subject to ongoing monitoring by Project Seagrass to validate the effectiveness of the new planting regime. “We are excited by the planting results, and we must now see how this method of planting works in Dale” says Richard Unsworth, Associate Professor Swansea University.