BIM expert Tekla has described how its software and 3D modelling environment have helped coordinate the various activities involved in the construction of Tideway’s Carnwath Road shaft.

Tideway is a multi-billion-pound project, designed to transform London’s existing 150-year-old sewer system with the construction of a new 25km ‘super sewer’ underneath the capital city and River Thames. It has a complex series of construction works, sites and shafts all over the city.

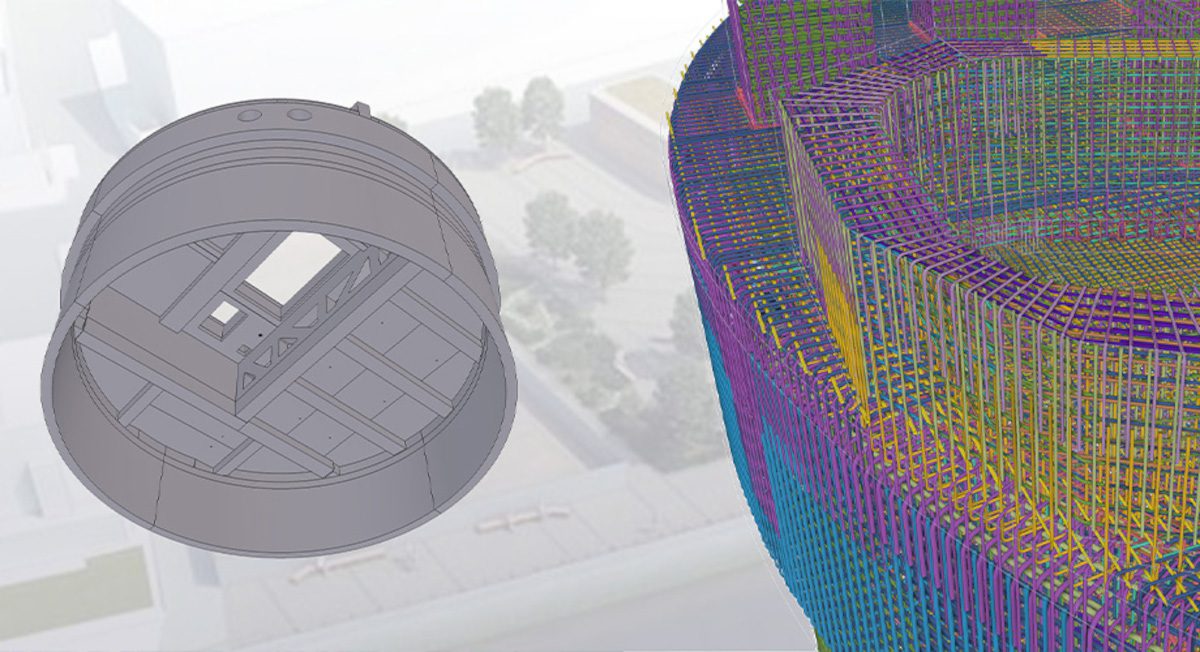

The Carnwath Road shaft in Fulham is one example, measuring 25 metres in diameter and with a depth of 42 metres. Initially constructed to launch the main tunnel boring machinery for Tideway West, the shaft was subsequently used to extract the spoil from the tunnelling works, which, utilising the riverside location, could then be removed by barge. Once completed, the shaft will provide a junction between three tunnels and have a mezzanine chamber level for plant equipment and access. At the surface, the area will be landscaped to provide a public space on the north bank of the Thames.

Hewson Consulting, the civil, structural and geotechnical consultant, was appointed by BMB Joint Venture in early 2022, tasked with detailing and modelling the upper shaft structure. Speaking about the project, David Wilson, Principal Engineer at Hewson Consulting, said: “While works had already commenced on the Carnwath Road site when we were appointed, BMB JV wished to explore changes to the construction methodology for the upper shaft structure, which formed the initial part of our contract. The focus was on improving the efficiency and delivery of the overall programme schedule, which was understandably a key priority.

“After consideration, a hung truss solution was developed for the upper structure, enabling site teams to cast the slip-form secondary lining of the whole shaft in a single streamlined process, rather than casting the shaft lining in two phases – the second of which would have required a colossal volume of falsework supported off the base of the shaft.”

In addition to the two underslung steel transfer trusses, Hewson Consulting’s proposed design also featured 37 precast elements.

“Coming into the project at a slightly later stage obviously came with its challenges,” David continued. “A lot of the complex geometry had already been confirmed, following rounds of designs that came previously. All other areas and the M&E models were in the process of being finalised as we were working on the project, meaning that there was limited scope to amend the existing design geometry.

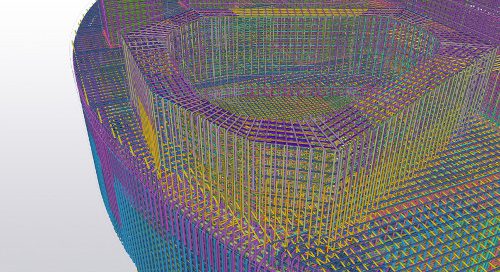

“We were able to model all of these geometrically complex interfaces and keep track of design changes in Tekla Structures. By considering the design in a detailed 3D environment, we could really visualise how all the individual elements would work and fit together on site. It would have been much more difficult to deliver the design to such high degrees of accuracy without Tekla software and the 3D modelling environment it provides. This also helped us to identify any potential clashes, which we were then able to resolve before reaching the site.”

Coordination and constructability were understandably key factors on the project. As well as coordinating with the various M&E elements and the interfaces between the multiple precast and prefabricated members of the re-design, Hewson Consulting had to also consider the shaft’s operation and maintenance requirements too.

David explained: “We had regular meetings with Tideway and other stakeholders, during which we had to demonstrate that we were providing sufficient space for the operations and site teams throughout the redesign process, and that there wasn’t going to be an impact on the pre-approved plans and strategies. Being able to bring up the Tekla model and visually demonstrate our plans and proposals was key in allaying these concerns.

“Similarly, we were able to use the 3D model to plan out access and working methods in advance, which presented a major safety advantage. Working with precast concrete and taking a DfMA approach, we had to design the concrete elements with enough tolerance to ensure everything would fit on site. By sharing the development model with the site team via Trimble Connect, we were able to get their feedback on whether the design would be constructible or if there was adequate space to safely work. In essence, by being able to explore the model as it was being created, the contractor team could benefit from a ‘digital rehearsal’ of the works.”

Working with reinforced concrete elements presented another challenge on the project, with the potential for some highly congested areas of rebar and complex detailing. By working in 3D, Hewson Consulting was able to easily identify any congestion or potential ‘problem areas’ and adjust the design in light of this.

David concluded: “The value of the digital software and the coordination and accuracy it offered us was evident in the limited number of issues we encountered as the works progressed on site. Likewise, the construction of the slip-formed secondary wall lining ran incredibly smoothly and was completed with zero issues associated with the reinforcement design detailed in Tekla.”

Tideway is expected to be completed in 2025. Hewson Consulting’s work on the project saw the team win ‘Infrastructure Project’ in the 2023 UK Tekla Awards, with judges praising the excellent combination of steel and concrete structures in the 3D model and the use of Trimble Connect to collaborate with other team members as a ‘shining example of innovation and excellence’.

On winning the award, David commented “I am really proud of the team who worked tirelessly to deliver this project, and this was only made possible by the use of Tekla Structures which enabled numerous users to be working in the model simultaneously. To receive the recognition from Tekla Structures by winning the infrastructure category is the icing on the cake.”

For more information, please visit: www.tekla.com/uk.