A wide variety of factors can affect the quality of potable water during treatment, ranging from the characteristics of the source water to factors such as the chemicals used to treat it and the design of the treatment plant itself. Julian Edwards, Continuous Water Analysis Product Manager for ABB Measurement & Analytics in the UK, explains the importance of selecting the appropriate measurement and analysis equipment for potable water treatment applications.

The average UK home uses 140 litres of water a day, 56 litres in the bathroom and 31 litres in the toilets.1 This demand for water is increasing and is predicted to outstrip supplies by 40 percent by 2030, with even England on course for water shortages within 25 years.

With climate stress adding to the equation, rising consumption will meet decreasing supply, at which point we simply will not have enough water to supply our needs.

As regulations for water quality become more stringent, added to increasing pressure from customers to provide consistent water quality and rising demand, the water supply industry is continually challenged to optimize water treatment processes, with part of that focus on the testing regimes and how and how often water is analyzed.

Traditionally, testing entailed extracting samples for laboratory analysis and applying the results to the overall condition of the process. Such an approach can only give information for a particular set of conditions at a single moment in time. Because the results are only valid for the time when the test was conducted, the operator is unable to obtain real-time data from their process. This makes this method inappropriate for today’s demand, which now requires raw water to be extracted from multiple sources and blended before treatment.

Continuous Water Analysis (CWA) systems are the best way to meet these needs as they give highly accurate, up to the minute information on conditions.

Whether it’s measuring the quality of incoming raw water from streams, rivers or sources such as boreholes, or performing a final check before the treated water enters the distribution network, an online device can provide continuous measurement and offers several advantages over purely manual methods. With online CWA systems, samples are automatically extracted and analyzed at regular intervals without the need for time-consuming and potentially inaccurate manual sample collection.

A real-time snapshot of process conditions as they exist also allows operators to take immediate action if any issues occur.

With the added benefit of digital based instruments, CWA systems offer reliable measurement data, are simpler to operate and maintain, and provide flexible communications. Combined with advanced digital predictive maintenance, they can help maintain the quality of drinking water while ensuring that analytic equipment and thus processes remain almost constantly online.

These systems help achieve improvements in treated water quality, increase process efficiency, and reduce use of chemicals and energy, as well as cutting maintenance and personnel costs.

Think local

Various local and seasonal conditions and legislation will play a role in the equipment and analyzers chosen for the system.

The first stage is to source the water. In the UK, surface water accounts for 72 percent of water intake, with the remaining 28 percent from underground sources.

The source of the water is important when building the CWA system, as its geology and geography, vegetation in the area, and human activities determine the initial contaminants. Lowland sources can be contaminated by pesticides and organic matter, while highland or well water sources can have significant quantities of minerals such as iron and manganese. When entering the distribution system, these minerals can cause poor aesthetic quality of the water, or deposition on pipe surfaces. As soluble minerals, they must first be chemically converted to an insoluble form that can be easily filtered out.

Because of this, there are a number of parameters that need to be measured or considered in the water intake phase of the water treatment process. Some of them depend on the level of other parameters, affecting the makeup of the CWA system that monitors them.

Ammonia can affect the health of animals and people. Its toxicity depends on the pH value of the water as well as the temperature. Generally, the higher the pH value, the greater the proportion of ionized ammonia, which increases the toxic effect – raised temperature also increases the proportion of NH4+.

Conductivity is another measurement used in drinking water as an indication of its purity. The level of dissolved ions can change the conductivity of water. In general, the higher the contaminant levels, the greater the conductivity. Measured in microSiemens per centimeter or µS/cm, typical drinking water will be between 200 and 1000µs/cm.

Conductivity also depends on the temperature of the water – as temperature rises, conductivity increases. This is why measurement of conductivity of a water source is best done in situ, as taking a small sample will alter the temperature and therefore the conductivity value. High conductivity of the order of one to 10 µS/cm could be an indicator that the water source has been affected by industrial processes.

In its natural, pre-treated state, all water contains particulate matter that will need to be removed before it is deemed to be completely safe to drink. The visual appearance of this water can vary depending on its quality and the quantity of the suspended particulates.

A sample is turbid when particulate matter in the water makes it cloudy and difficult to see through after a certain distance. Turbidity levels are measured using a turbidimeter, which uses a light beam and a light detector. Turbidity meters are used extensively in the water treatment cycle, ranging from the measurement of incoming source water, checking the effectiveness of the coagulation and filtrations steps, to monitoring of final effluent prior to distribution, ensuring the water is safe to drink and free of potentially harmful microorganisms.

Nitrates, which are another key parameter in drinking water, are found in both ground and surface water, usually from agricultural runoff or industrial waste. If present in drinking water beyond a certain threshold, it can be fatal, especially for infants. Nitrates are most commonly measured using ultraviolet (UV) spectrophotometry. Nitrates absorb UV light at particular wavelengths, giving a rapid way of determining the nitrate content and ensuring the correct mitigation actions can be taken to lower its concentration.

Building the right system

Continuous assessment and real-time dosing of water inputs was the basis of a system designed by ABB for use on a potable water treatment works. The system replaced an obsolete automatic coagulant dosing system that was reaching the end of its life. The customer also wanted improved control and instrumentation to cut OPEX by reducing dosing needs and maintenance effort.

In the initial design stages, the company assessed potential replacement systems and met with other water utilities to compare products and share best practice.

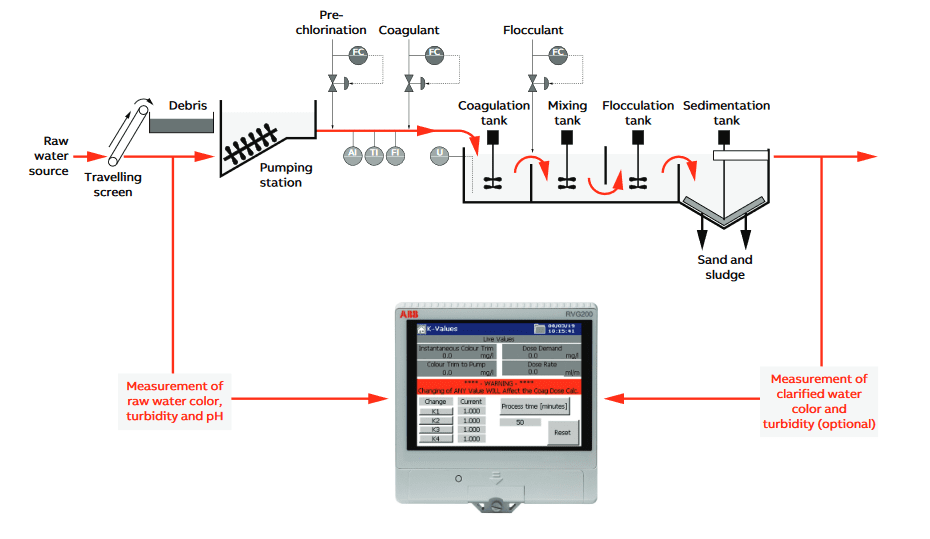

After conducting an initial search, the water company found no readily available solution in the market that met all its requirements. To meets its needs, ABB needed to develop a continuous measurement and control system, combining high and low-range UV organics (DOC), surrogate colour, turbidity, and pH analyzers with an RVG200 controller/recorder.

The system calculates the amount of coagulant that will allow effective removal of particulates through sedimentation and filtration. Using real-time data from analyzers, the RVG200 adjusts the level of coagulant dosing. This gives values for the actual required dose (mg/l) and dose rate (mls/min), used to ensure that the coagulant accounts for seasonal fluctuations in raw water or physical changes to the process.

The feedback control adjusts the coagulant dose by maintaining colour for the clarified water within a set target band. This helps negate possible process inefficiencies and ensures that effective treatment is achieved and maintained at subsequent treatment stages, such as filtration/disinfection.

The system can be adjusted to handle any variations upstream, while using an Ethernet connection enables remote condition monitoring.

After a year of operation, the water company uses 12 percent less coagulant, has cut maintenance by over half, and has reliable control in line with raw water quality changes.

With the right instruments for the right job and an appropriate control system, continuous water quality measurement can go a long way to meeting the requirements of the regulators while also keeping the cost of potable water processing under control.

References

[1] https://www.bbc.co.uk/news/uk-47620228