Researchers from ICIQ in Spain have designed micromotors that move around on their own to purify wastewater. The process creates ammonia, which can serve as a green energy source. Now, an AI method developed at the University of Gothenburg will be used to tune the motors to achieve the best possible results.

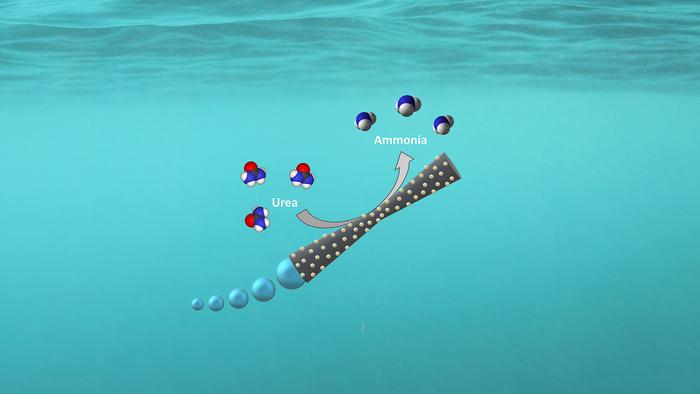

Micromotors have emerged as a promising tool for environmental remediation, largely due to their ability to autonomously navigate and perform specific tasks on a microscale. The micromotor is comprised of a tube made of silicon and manganese dioxide in which chemical reactions cause the release of bubbles from one end. These bubbles act as a motor that sets the tube in motion.

Researchers from the Institute of Chemical Research of Catalonia (ICIQ) have built a micromotor covered with the chemical compound laccase, which accelerates the conversion of urea found in polluted water into ammonia when it comes into contact with the motor.

Green energy source

“This is an interesting discovery. Today, water treatment plants have trouble breaking down all the urea, which results in eutrophication when the water is released. This is a serious problem in urban areas in particular,” says Rebeca Ferrer, a PhD student at Doctor Katherine Villa´s group at ICIQ.

Converting urea into ammonia offers other advantages as well. If you can extract the ammonia from the water, you also have a source of green energy as ammonia can be converted into hydrogen.

There is a great deal of development work to be done, with the bubbles produced by the micromotors posing a problem for researchers.

“We need to optimise the design so that the tubes can purify the water as efficiently as possible. To do this, we need to see how they move and how long they continue working, but this is difficult to see under a microscope because the bubbles obscure the view,” Ferrer explains.

Much development work remains

However, thanks to an AI method developed by researchers at the University of Gothenburg, it is possible to estimate the movements of the micromotors under a microscope. Machine learning enables several motors in the liquid to be monitored simultaneously.

“If we cannot monitor the micromotor, we cannot develop it. Our AI works well in a laboratory environment, which is where the development work is currently under way,” says Harshith Bachimanchi, a PhD student at the Department of Physics, University of Gothenburg.

The researchers have trouble saying how long it will be before urban water treatment plants can also become energy producers. Much development work remains, including on the AI method, which needs to be modified to work in large-scale trials.

“Our goal is to tune the motors to perfection,” Bachimanchi ends.