A recent project blends leftover cooking oil, lamb fat and agricultural waste to develop a cleaner fuel for ships.

The researchers – from Aston University – have blended mixed waste pellets with either used oil or animal fat to develop a form of energy which meets international marine fuel standards.

Currently most vessels run on an oil refinery waste product called bunker fuel, but it presents several environmental concerns including the risk of oil spill and the emission of toxic compounds and particulates. In 2020 the UN banned the use of heavy fuel oil in the Arctic, following its ban in Antarctic waters in 2011.

Now scientists at Aston University have combined waste material supplied by a Dutch anaerobic digestion plant with used oil or fat to create a blend which could be a replacement for bunker oil. Their research “Investigation of anaerobic digested pyrolysis oil and waste derived biodiesel blends as sustainable fuel for marine engine application” has been published in the journal Fuel.

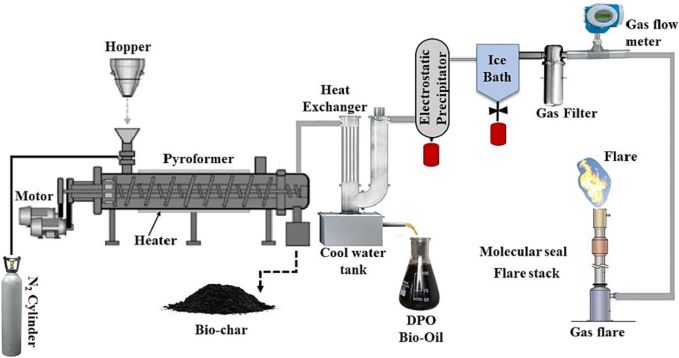

The waste pellets were treated in Aston University’s pyrolysis-based reactor which heated them up to 500 °C to convert them into bio-oil.

Solvents were added to the bio-oil which was then blended with the used cooking oil or fat to create the fuel.

Dr Abul Kalam Hossain, senior lecturer in the Department of Mechanical, Biomedical and Design Engineering, said “Over the past ten years both the volume of marine transport and the corresponding greenhouse gas emissions have increased steadily.

“We knew of the potential of pyrolysis oils as renewable biofuels for use at sea in diesel engines. However, due to their low energy content, high acidity and viscosity we knew they needed to be improved.”

The researchers created five blends adding differing amounts of bio-oil, solvent and oil or fat and stored them in the dark for eight months.

Tests showed the blends had improved their heat value, viscosity and density by around 25 to 40% and complied with Marine Fuel Standards (ISO 8216 and ISO 8217) for use in diesel engines and boilers.

The paper states the oil blends can be used in stationary diesel engines as well as marine diesel engines for power generation.

The research illustrates how biomass pyrolysis technology has developed into a sustainable technique which can turn food and agricultural waste into bio-oil. The study’s results could eventually contribute to better global air quality.

The Aston University research team worked alongside academics at the School of Architecture, Technology and Engineering University of Brighton, Indian Institute of Technology Madras, India and the College of Engineering Guindy, Anna University, Chennai, India.

Investigation of anaerobic digested pyrolysis oil and waste derived biodiesel blends as sustainable fuel for marine engine application – ScienceDirect