This article contains paid for content produced in collaboration with Arvia Technology.

Active Pharmaceutical Ingredients (APIs) are notoriously difficult to remove from wastewater. Traditional water treatment systems do not easily remove APIs from water, so pharmaceutical companies often have to resort to high-cost incineration instead.

Client: Global Pharmaceutical Company

A well-known pharma company approached Arvia because of the exact scenario above. The current disposal solution was incineration but they wanted to find a better solution which was not as costly, either financially or to the environment.

Problem: To reduce four APIs to PNEC levels

The pharma giant needed to remove four APIs: ibrutinib, topiramate, rilpivirine (TMC278) and paliperidone palmitate. All four APIs had to be reduced to below PNEC levels (Predicted No-Effect Concentration). No traditional water treatment systems were able to do this, so the pharma company had to look at new technology.

Solution

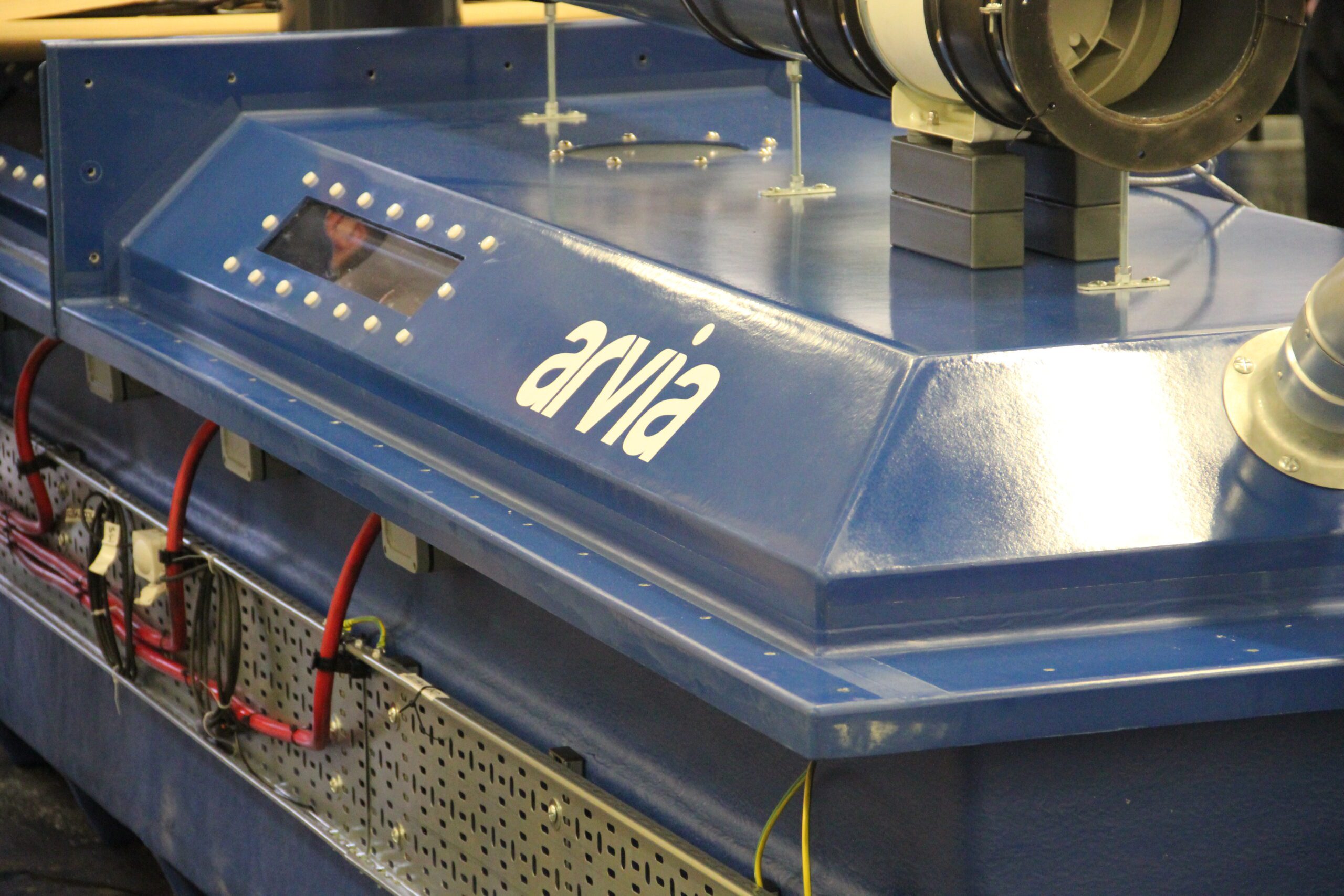

Arvia Technology specialises in electrochemical oxidation for removal of persistent organic compounds from industrial wastewater. The range is called Nyex, and they are all based on a super-efficient electrochemical oxidation process, either with or without an integral adsorption process in the same unit.

For this project, Nyex Ellenox followed by Nyex Rosalox reduced all four APIs to below PNEC values. To see how the Rosalox works, see this short animation:

And for a description of the products see: https://arviatechnology.com/water-treatment-products/

Result

Nyex Ellenox and Nyes Rosalox in combination was shown to remove all four APIs to below the required levels which meant the pharma company could avoid the costs of incineration

- Topiramate 1000μg/L

- Ibrutinib 1.55μg/L

- Ripilvirine 2.0μg/L

- Paliperidone palmitate 250 μg/L

Arvia’s CEO, Simon Gatcliffe said, “Our client had budgeted for 1000 tonnes per year to be incinerated, which equates to about 460,000 Euros. Our solution represents a very strong ROI.”