Environmental technology company Smart Ops launched a biotechnology solution said to improve global access to clean water, on 21 May. The Smarts Ops SCR System is the first “water treatment and rejuvenation technology to gain official verification from the Government of India’s Ministry of Water (Jal Shakti)”.

Smart Ops’ technology is inspired by nature, says the group, using advances in material science, biotechnology, and engineering “to achieve in hours what can take legacy water treatment technology or natural process months or even years”.

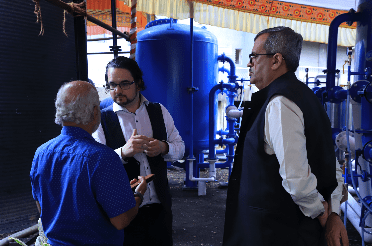

It was founded by Irish inventor and entrepreneur Dr Liam Ryan, along with UK businessmen Minesh Patel and Priyesh Patel MBE.

“The Smart Ops research team has spent the past two years perfecting SABRE Spheres (short for stabilised aerobic or anaerobic bioengineered reaction environment), developed from seaweed waste and containing targeted natural bacteria and enzymes, which mimic the ability of oysters to naturally filter and breakdown substrates. This technology is at the heart of the Smart Ops SCR System, which provides active continuous filtration that massively reduces the cost, infrastructure, and energy requirements of delivering clean, usable water in domestic, commercial and broader environmental settings.”

Currently in the first wave of its commercial deployment, the Smart Ops system is now being deployed in over ten projects across India purifying and cleaning millions of litres of water and with more than hundreds of millions of litres of daily water treatment in the pipeline over the coming months.

A smarter solution?

As Smart Ops explains it, conventional, centralised water treatment and sewage plants require extensive infrastructure (such as sewer networks) and a large land footprint to function properly increasing cost, disruption and environmental footprint. The Smart Ops SCR System uses 10% of the land footprint, zero concrete and requires no large sewer network. It creates a system that can be deployed locally, which then treats and recycles water for multiple uses in a cost-effective way with minimal environmental impact.

The company says it has successfully completed a number of test projects globally. Across India, Smart Ops has been working closely with local municipalities, central government, and Industrial partners, to tackle industrial and municipal water sources and polluted public water bodies, where conventional treatment solutions are not fit for purpose.

“Smart Ops has been able to bring 18 million litres of polluted water to safe levels within 48 hours in Ganesh Lake in Mumbai. In Pimpri (Pune), the company is currently treating water in four lakes totalling over 2500 million litres and tackling the spread of water hyacinth along three rivers.”

Another variation of the technology is set to tackle an infestation of mosquitoes on water bodies with trials with Kenya Medical Research Institute to commence in Kenya shortly.

Minesh Patel, Director at Smart Ops added: “Communities and industries around the world are losing access to water where the conventional model of water treatment isn’t keeping pace with pollution levels. In Mumbai, for example, essential businesses had to shut down multiple times last year with water cuts for up to 13 days. With a new model for smaller, modular treatment, we can restore access to water and help the environment recover. We’re here as long as we need to be; where a lot of other interventions involve a one-off solution involving a lot of concrete and chemicals, our business model is linked directly to the water we deliver, so we have a lot more skin in the game.”

Smart Ops has become the first company working in large-scale water treatment across India, to receive certification as part of the Governmental Environment Technology verification programme. This follows strenuous testing of Smart Ops technology and its ability to meet and adhere to rigorous industry standards. “The company was able to demonstrate that it can deploy the Smart Ops SCR System in just 15% of the time taken by current conventional treatment systems, that it uses a fraction of the land space (<10%) and is capable of being deployed on waste land or floated over water bodies to treat water as close to the source of pollution as possible.”

The Governmental Environment Technology Verification paves the way for Smart Ops technology to be officially certified in India for:

· Decentralised Sewage treatment plants ranging in size from 0.2 up to 100 million litres per day

· Retrofitting to existing underperforming sewage treatment plants

· Cleaning of lakes, rivers and other polluted water ways including open sewers

· Industrial applications such as poultry farms, dye house and sugar cane/bioethanol industries

“This certification paves the way for Smart-Ops’ rapid growth in India and globally, using India as our site of production as well as our largest market currently. In just 24 months we’ve gone from being an idea that we were discussing as friends looking to make a difference, to having successfully won municipal contracts and setting up a facility in India, as well as opening research offices in both the North and South of Ireland, and our head office in Leicester in the UK,” said Dr Liam Ryan Director at Smart Ops.

He continued: “To this day it takes my breath away every time we deploy on a polluted water body and show people that this once smelly and highly degraded watercourse or sewer water can be cleaned and start improving the quality of their lives – far beyond what they might originally think is possible. It’s such a privilege to see my technology used to have a real impact on people’s lives.”

The biotechnology that underpins Smart Ops’ SABRE Spheres, was first industrially tested in Leicester UK, where it was deployed to improve the environment around the Patels’ Cofresh factory, a leading national food manufacturer, that has made iconic Indian snacks for over five decades.