An independent1 trial of Advanced Hydrogen Technologies (AHT) Group’s carbon clean and capture device has reported significantly lower emissions and increased fuel efficiency from a Class 08 locomotive, says the group.

During the breakthrough two-week testing2 on a 1960s shunter – carried out at the world-class Very Light Rail National Innovation Centre in the West Midlands – overall exhaust gas emissions were reduced by 22% and heavy particulates by 20%, while diesel efficiency savings of 8% were achieved too.

This groundbreaking study is a joint venture partnership between cleantech pioneers AHT and Harry Needle Railroad Company (HNRC) who are leaders in the storage and maintenance of rail vehicles. It forms part of the Clean Futures programme recently run by the Black Country Innovative Manufacturing Organisation (BCIMO), which includes the unique Rail Development & Test facility at its £32million site in Dudley.

The first week of testing saw AHT’s revolutionary four cell system hydrogen generator3 ‘clean’ the HNRC’s Class 08 locomotive by removing residual carbon build up, which is worst in diesel and older engines, while the following week a bespoke ‘capture’ device was added, which further reduced harmful emissions and particulates to complete the process.

Marcus Mayers of HNRC said: “This was the ideal opportunity to solve the pressing issue of how to measure and quantify the benefits of hydrogen, which has been holding us back for years. Access to both AHT’s specialist technology and BCIMO’s outstanding testing facilities has given us the data and backing we need to have a proven business investment case for upgrading our locomotives.”

AHT CEO, Ben Kattenhorn, commented: “These landmark results are further proof that our award-winning proprietary technology reduces carbon footprint and fuel costs, while helping businesses meet their Net Zero targets. We also know these figures get even better over time, because a recent 18-month study on HGVs reduced the worst emissions by over 91%.

“Rail is one of the sectors most under scrutiny, but Engine Carbon Clean and Capture offers an immediate solution – also restoring engine efficiency and power, lowering maintenance costs, extending the lifespan of assets and aligning with the new ESG requirements of the International Financial Reporting Standards mandate.”

During testing, a baseline reading was compared with those generated post clean after the R4 hydrogen generator was fitted, which determined the average 8% fuel saving. Likewise, individual emissions reductions of 27% Carbon Monoxide, 8% Carbon Dioxide, 22% Nitric Oxide, 12% Nitrogen Dioxide and 39% Formaldehyde were achieved.

The capture device further reduced particulate matter by a fifth (20%) and specifically those less than 2.5 micron in diameter, which are strongly associated with detrimental health effects. Particulate Matter (PM) 2.5 remain airborne for long periods and can be drawn deeper into the lungs and bloodstream.

The way the hydrogen is delivered means it is not detrimental to any component within the engine – it only targets carbon build-up – so streamlining heavy duty commercial vehicles in this way can benefit a business from both a cost-cutting and environmental perspective and without removing any parts or using any harsh chemicals.

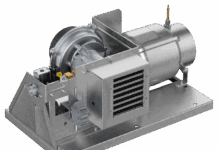

What’s more, AHT’s Engine Carbon Clean & Capture system is completely modular and can be fitted to any sized or type of locomotive and will soon be mainline certified to give tangible results that contribute to the bottom line – see visual 1 on typical locomotive savings per annum.

Notes

[1] Carried out in March 2024 by independent testing specialists Atmo, who use the latest software, IoT and data analysis to optimise asset usage and reduce environmental emissions.

[2] Over 17,000 air pollutant and exhaust gas emission readings were taken via MCERTS-accredited air quality sensors. Each testing day followed the same methodology with newly calibrated sensors keeping track and tunnel location, air quality sensor placement, loco speed, plus amps consistent for every test.

[3] This revolutionary system takes ordinary tap water and turns it into pure medical-grade hydrogen and oxygen on demand, which can be used in multiple disciplines and industries. The water to be processed does not require cleaning as the AHT R4 Generator has a unique military-grade filter which prepares even unclean water for use. When burned, the sole by-product is harmless water.