As international pressure mounts on industry to clean up its act and make bigger energy savings, companies have had to respond by adapting their products.

CSG supplies civil engineering products to the sewage and waste water sectors and it reacted by developing its range to meet demands for ‘sustainability-focused’ solutions and to recoup energy gains from sludge.

Waste water treatment plants are big consumers of electric power, especially when nitrification is involved in the biological process, so it is desirable for plants to recover and make best use of the energy that is contained in the sludge they generate.

Energy recovered from sewage sludge goes a long way towards making the treatment process energy self-sufficient, and in some cases producing a high percentage of the requirements of the entire treatment works site. It eliminates the need for large amounts of grid electricity and has the added benefit of reduced energy use and costs.

CSG (Castings Services Group) said its portfolio has been specifically designed to ensure customers are ahead of the game in sludge handling technology such as anaerobic digestion (AD), and advanced anaerobic digestion (AAD) which allow the recovery of energy in sludge generated by a wastewater treatment plant, to be converted into electric power.

Dave Warner, divisional manager of CSG’s new process and actuation division, explained: “For decades we have been providing solutions for the sewage and sludge industries. However in recent years, as the industrial landscape has evolved in the production of energy from waste, we find ourselves facing a different set of circumstance to overcome on behalf of our customers mainly in the control of imported sludge.

“We are presented with challenges in the types of products and solutions we offer to our customers. Whereas, a decade ago we were dealing with sewage, now as energy from waste sites and landfill we deal with the by-products of releasing energy from sludge, including leachate and various imported waste like oils and fats. These occur in varying concentrations, can be of an irregular consistency and are incredibly pungent and attack elastomers on the sludge handling equipment.”

The treatment methods of some of the sludge produced vary widely; for instance to kill e-coli the sludge needs to be heated to over 72°C and held at that temperature for more than an hour. “This gives us an issue in terms of providing a valve system with an elastomer resilient to these sustained high temperatures,” said Warner. “A gate valve with an EPDM wedge is no good as oils and fats will expand the rubber; nitrile has a heat limitation, so we consider products that contain Viton (FKM) of neoprene which is a bit non-standard for the UK market.

“Additionally, we still encounter the usual ragging up and now we are also finding on the energy from waste sites that you can find the odd solid object, i.e. glass, wood, bottle tops, which again can damage a seal.”

One of the most significant renewable technologies in addressing Britain’s international commitments to tackle climate change is AD, and in the last five years AAD, which recovers significant quantities of energy from sludge. AD is the breakdown of organic materials by natural bacteria to produce biogas from waste biodegradable materials including sewage sludge. AAD takes this process a stage further, and enhances the benefits of anaerobic digestion by separating and optimising the key process stages used in more conventional digestion systems.

The process and actuation division recently completed a project working with GTM (Galliford Try & Imtech Process) on Anglian Water special projects, which involved specifying and supplying the complete scope of valves for two projects. With a combined value of £320,000, the two installations were designed to enhance the AAD facilities at Basildon and Cliff Quay sewage works in Essex by capitalising on the generation of gas for renewable energy such as electricity, consequently boosting sustainability.

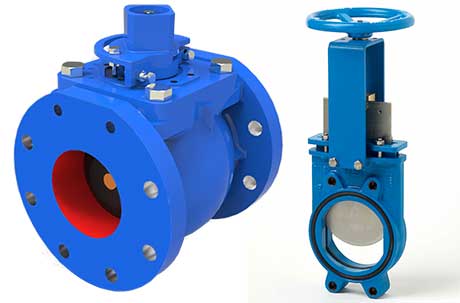

Valves are equipped to handle each stage of the AAD process: robust Orbinox bi-directional knife valves cope with the raw dense waste; Mueller eccentric plug valves manage the flow through the pipes; butterfly valves adjust levels of gas. The Mueller valve can be used on screened sludge for isolation and control applications. The plug valve can be installed having the seat on either the inlet or outlet side of the valve – that bi-directional function means that when the valve is closed the media doesn’t become trapped in the valve body, thus keeping the bearings out of the sludge.

The natural closing action of a plug valve means increased velocity across the seat, removing any debris that might prevent closure.

For unscreened sludge, the bi-directional knife valve made by Orbinox is “the true market leader”, according to CSG. The EBES valve is ideally suited for this type of application offering a full bore with no areas for snagging. The elastomer which gives a tight shut off is an edge seal encapsulated within the valve body again outside the flow. The main advantage of an Orbinox Knife valve over a wedge gate valve is that the spindle and wedge nut are all outside the flow, meaning the valve will not rag up an cause the valve to fail which the company said is a common complaint on a wedge gate valve.

Warner added: “AAD offers not only a waste treatment solution but one that delivers a significant energy source and a reduction in sludge volumes. We believe supplying our products to renewable energy projects such as Anglia’s will be a big growth area for our business moving forward.”