Wastewater plant operators face the problem of pump blockage – resulting from large quantities of grit, debris and fibrous matter – on a daily basis. The fouling of pump impellers is a longstanding problem and costs a lot in terms of plant downtime, pump repair and even pump replacement. AxFlow discusses the problem here.

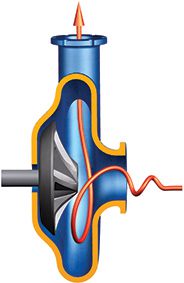

AxFlow’s technical support manager Mark Redgrove says the torque-flow pump has the ability to withstand the harshest of conditions due to its hydraulic vortex pump technique. The vortex is created by the rotating recessed cup-shaped impeller extending into the suction line, drawing the liquid / solids into the pump and then quickly through the discharge, whilst minimising the fluid / solids contact with the impeller and volute This simple design allows solids to pass through the pump without choking the impeller, considerably reducing pump wear and the potential for blockages.

Cupped vs radial design

With radial impeller design pumps, grit is discharged at high velocity against the pump casing or the wear ring. Unlike radial impeller vortex pumps, the cupped impeller action of the Wemco pump deflects material away from the case and back into the flow stream towards the extra-thick sacrificial suction piece. Behind the impeller is a High Chrome Iron wear plate which can withstand the grinding action of grit. To further maximise performance and minimise wear, the large diameter impeller design is the key to the pump’s considerable durability and non-clogging performance.

Because the suction end of the pump is exposed to the greatest abrasive wear the pump case comes in two parts. The replaceable suction piece is sacrificial, even though it is designed for long wear life. Replacing it is an easy operation involving breaking the suction flange, removing the slotted bolts and then installing the new suction piece. The job can be performed in just a few hours and is considerably cheaper than a completely new pump case.

AxFlow offers the pump in various configurations, including close-coupled, horizontal or vertical mounting, cantilever designs and a small range of submersible units. “We can satisfy many of the challenging wastewater and effluent pumping applications that face both the water utilities and companies which generate large volumes of solids-borne waste liquids,” says Mark Redgrove. “Our Wemco WSP heavy duty self-priming pump is equally at ease with clean and solids laden liquids due to its open type two-vane impeller. Self-priming pumps are ideally suited to any duty in wastewater treatment for applications with a suction lift where ease of access to the pump is necessary for maintenance purposes.”

The current water treatment works at Sandon Dock, Liverpool is the second largest wastewater treatment plant in the North West of England and is capable of treating up to 950million litres of sewage a day (11,000 litres/sec).

The removal of grit at the wastewater intake stage is where the Wemco pumps are first employed. In spite of the considerable and aggressive solids content, United Utilities reports that the only maintenance that these grit pumps require is the occasional replacement of the mechanical seals.

Further along in the treatment process, the grit-free wastewater is transferred into six settling tanks where it is held for up to 10 hours. Each tank is equipped with three Wemco M4C pumps for the purpose of removing the sludge from the tanks and transferring it to the dewatering plant. In the 12 years that the sludge pumps have been operating, no refurbishment work has been performed on the impellers.