Even if Brexit has a negative impact on the drivers for adopting more sustainable technology, Britain’s food industry will benefit from reducing its environmental impact by investing in more effective residue management practices. As interest in the circular economy grows, food companies will need to make better use of their process residues in order to remain competitive. Richard Gueterbock of on-site digestion technology specialist Clearfleau looks at what can be done to help smaller SME food and drink businesses in the UK secure access to such technologies.

Adding value to process residues can reduce operational costs and generate revenue. On-site digestion (of process residues on farms as well as on factory sites) is a growing contributor to renewable energy, where the UK has been taking a lead on bio-energy technology development. Corporate expectations are now changing across the food processing sector, with global Industry leaders backing the concept of generating energy from production and processing residues. Following the Paris Climate Change Summit carbon reduction is becoming a higher priority for the food processing sector and should be supported by policy makers.

More companies in Britain’s food industry are realising that process residues can be a source of renewable energy rather than just an unwanted cost. Hence, with new plants on sites operated by multinationals like Diageo or Nestle, more support is needed to encourage the smaller (SME) processing companies to adopt a similar approach, to help decarbonise our food supply chain.

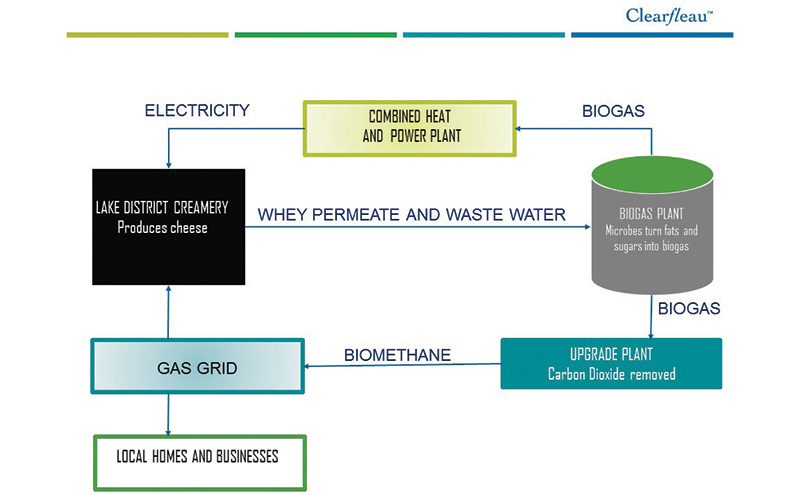

Cheese-to-biogas installation

With some high-profile plants on larger processing sites, opportunities exist for the smaller food processing businesses that proliferate in the food and drink sector to follow suit. Clearfleau’s latest on-site AD plant is supplying energy to First Milk’s Aspatria cheese creamery (sufficient to heat the equivalent of 4,000 homes) in Cumbria. On-site digestion is converting liquid process residues from cheese-making into biogas for use in the creamery (see block diagram below).

Lake District Biogas (www.lakedistrictbiogas.com) was set up to manage the project, allowing First Milk to concentrate on its milk-processing activity. The plant will remove 7,000 tonnes of carbon per annum from the supply chain. While reducing fuel costs and carbon emissions, the plant will also supply green gas to local houses and reduce traffic on local roads.

This is the first on-site AD bio-energy plant to feed gas into the gas grid, based only on treating residues from cheese-making, without using other non-dairy feedstocks. Another UK cheese maker, Wyke Farms (in Somerset) also has a plant injecting gas to the grid but this is also fed with farm residues and crops grown to supply the AD plant.

On-site digestion can produce base load for use at the point where bio-degradable residues are produced, by capturing methane that would otherwise be released. For materials like whey or other fatty process residues, revenue from on-site AD can outweigh returns from other markets and provide a better return on investment than conventional treatment and disposal options.

Transition to the circular economy

With competing demands on funds available for investment, particularly in smaller companies, food businesses need encouragement to become more sustainable and reduce fossil fuel use. More widespread development of smaller-scale bio-energy plants requires confidence in the incentive regime which will make it much easier to secure the funding to develop new plants.

After the recent Paris Climate Change Summit, CEOs of 10 global food and drink companies, including Unilever and Nestle declared that: “We want the facilities where we make our products to be powered by renewable energy, with nothing going to waste. As corporate leaders, we have been working hard toward these ends, but we can and must do more”.

This significant intervention from global business leaders is aligned with a wider vision for a more sustainable approach to on-site residue management. Politicians should welcome this statement and work with food industry leaders to respond to the challenge of de-carbonising food processing and supporting the sectors’ transition to a more circular economy.

Governments should recognize the value of on-site decentralised energy from process residues and the value of technologies that supply base load, generated where the energy is consumed.

In the past 5 years, over 20 on-site AD plants have been installed in the UK’s agri-food sector. However, relatively few AD plants have been installed on SME food processing sites. Now the recent unexpected reduction in incentive rates is threatening the development of such plants.

Policy support for on-site renewables

The regulatory framework should support investment in the wider adoption of bio-energy across the food industry to cut emissions, increase efficiencies and reduce costs. But, if we are to boost adoption of on-site AD among the SME businesses that proliferate in the UK food and drink sector, we need a more positive approach, including:

• Support for smaller companies to devote more resources to sustainability investment,

• Targeted pressure on carbon footprint reduction from stakeholders and UK regulators,

• Sustained access to renewables incentives for more risk averse SME food businesses,

• Help for businesses to embrace the circular economy by supporting on-site generation,

• More political support for renewable bio-energy, in place of other options like landfill.

Regulators could reinforce the message that bio-residues should be used for energy generation as a way of reducing emissions. But if politicians remain unwilling to reverse recent reductions in renewable incentives they should consider how else they can support the on-going de-carbonisation of food production.

Unhelpful plans to cut limited support for renewables, announced recently by DECC, have been condemned by commentators as a failure to follow up the UK commitment to the Paris summit. Post Brexit, we shall need to be even more competitive with EU food producers and if we want to sell our food products in Europe, we still need to comply with EU regulations.

More successful examples of profitable on-site renewables solutions, on smaller food and drink sites, will prove a point. We shall be building some smaller on-site plants in the next few years and there will be other examples of on-site renewables solutions in the food sector. But if progress towards greater sustainability is to be achieved, food industry stakeholders like the FDF (Food and Drink Federation) and the IGD (Institute for Grocery Distribution) need to work closely with politicians and policy makers to stimulate long term investment in renewables.

Regardless of political change, British SME food businesses need to become more sustainable. Hundreds of smaller on-site bio-energy plants will support delivery of renewables targets and provide wider economic, energy supply and environmental benefits. SME businesses require support from Government if they are expected to match companies like Nestle or First Milk in the adoption of sustainable technology and participation in the circular economy.