By Richard Gueterbock of Clearfleau Group

Carbon emissions continue to fall, despite legitimate concern that the Government has ‘taken its eye off the ball’ in relation to climate change. But the current political turbulence, combined with a lack of determination to build on the successes of the past decade, means that momentum is being lost.

With promises to deliver industrial resource efficiency being undermined, Westminster politicians are not matching efforts in Scotland to promote the circular economy and decentralised energy generation.

Regulatory pressures

The recent IPCC report highlighted the need for companies of all sizes to take responsibility for their carbon emissions and environmental impact. Across the board, British businesses are expected to become more resource efficient. The food and beverage sector in particular is facing pressure from regulators, due to its extensive impact on the natural environment and substantial carbon emissions.

While multinationals are implementing a range of resource efficiency actions on processing sites, the smaller and medium-sized food processors need encouragement to make their operations more resource savvy, greener and cleaner.

After Brexit, British industry will still be expected to match what competitors are doing elsewhere in Europe. Food and drink companies with long-standing European trade links will have to comply with EU rules on sustainability and resource efficiency. So how should British food businesses respond to pressures to develop low-carbon manufacturing solutions, as well as to boost energy and water efficiency?

Part of the answer is making better use of wastes and residues at the farm and factory level through on-site bio-energy generation. Leading food companies are promoting a more circular economy by implementing new ways of handling their process residues. Smaller businesses are also recognising the need to reduce carbon emissions on their factory sites and in the distribution of their products.

A sleeping giant?

The value of bio-energy is now starting to be recognised beyond the industry. The International Energy Agency described it as the “overlooked giant of renewables”. The UK’s Committee on Climate Change has advised that bio-energy could provide 15% of Britain’s total energy needs by 2050. Also, European companies like Arla (the UK’s largest dairy product supplier) and Danone have committed to being zero carbon by 2050, with bio-energy forming part of their strategy.

The Renewable Energy Association recently published the first phase of a comprehensive review into the future of bio-energy generated from bio-based feedstocks. This outlines how bio-energy can deliver a greater role in a low-carbon energy mix, to meet the existing 2032 carbon targets and the UK’s 2050 target for full decarbonisation. Policy and industry practice must evolve if bio-energy is to be fully part of efforts to reduce carbon emissions and curb fossil fuel use on factory sites.

All the residues from the food production chain have a latent energy value. Bio-degradable liquid effluents, residues, by-products and reject products can be transformed into valuable bio-energy. In future, the disposal or destruction of such bio-residues should be replaced with a circular approach, where everything has a use and a value. Resource efficiency will become part of everyday business language – just as artificial intelligence and smart solutions already are.

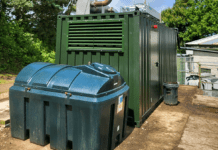

Bio-energy plants that extract the latent energy from organic residues can provide food processors with a competitive advantage, as well as access to decentralised energy. Creating a re-use value for effluent and process residues, including fossil fuel substitutes, should be at the core of the UK food sector’s longer-term strategy.

Exploiting latent value

Bio-energy, as part of the resource efficiency mix, enables factory sites to exploit the latent energy value of their by-products. However, in the UK, withdrawal of government support for bio-energy through the RHI (Renewable Heat Incentive) and FIT (Feed-in Tariff) has undermined growth in the sector at a time when businesses are starting to pay more attention to resource efficiency.

There is a policy vacuum and a lack of political leadership. With grants and generation incentives out of favour with politicians, how do they expect to promote change? As the incentive regime created over a decade ago is wound up, bio-energy investment is slowing down.

Whitehall can do more to stimulate greater industrial resource efficiency, including access to on-site bioenergy, to help British SMEs transition to more sustainable business models. But, it is time for the food processing and distribution industry to seek a wider consensus on what more can be done to help reduce carbon emissions across the food production chain.

Policy levers could include modifications to carbon taxation plans to provide incentives for smaller factory sites. Support for decentralised generation on food processing sites could embrace fossil fuel reduction targets or preferential loans for smaller businesses that invest in low-carbon solutions. Companies could be required to inform consumers on how they are reducing their use of fossil fuels and carbon emissions.

Our food industry must take its share of responsibility and embrace more responsible resource use. Smaller factory sites should be encouraged to invest in the extraction of latent energy from their residues and greater re-use of water. Cost savings will also drive the transition. We are working with factory sites developing both bio-energy and water recycling solutions to make production processes more efficient, as well as saving on disposal and operating costs.

Clearfleau and our colleagues at EnviroChemie can provide integrated on-site water and bio-energy solutions at both a large and smaller scale, making use of available technology to reduce carbon and use water more efficiently. With plants that deliver low-carbon heat and power on industrial sites, we can help businesses to recycle and re-use some of the large volume of water consumed in food processing. Biogas generated can also fuel HGV trucks that transport food from farms or factories to the consumer.

As the food and drink industry faces the uncertainties ahead, it needs to address the challenge of using resources more efficiently.

And Government can support industry by promoting the benefits of industrial grey water re-use and access to decentralised bio-energy as part of efforts to decarbonise manufacturing sites across the agri-food sector.