With environmental legislation in relation to odour management becoming increasingly more stringent, Italy-based environmental services firm Technologia & Ambiente (T&A) has purchased a Falco fixed, continuous photoionisation detector (PID) from instruments firm Ion Science. This will seemingly be a key component of its newly developed Online System for Monitoring Odours Treatment Efficiency (OSMOTREFF).

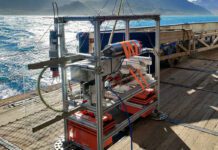

T&A’s OSMOTREFF is a pilot system specially designed to analyse odour treatment facilities. Once connected to odour treatment plant using physical chemical absorption, such as chemical scrubbing and activated carbon filtration, the OSMOTREFF provides on line monitoring of treatment efficiency and can conduct pilot tests on effluent gases to help further improve the process.

The odorous compounds contained in conveyed gaseous flows are difficult to monitor continuously because of their multiplicity, the peculiarity of the specific application and the sampling and analysis methodology.

Ion Science’s Falco PID is installed on the OSMOTREFF. It provides continuous, online measurement of volatile organic compounds (VOCs) in both inlet and outlet conveyed gas streams that have odour problems.

T&A’s Roberto Pisconti comments: “Odorous molecules are typically found in VOCs with a market tendency to be present in the vapour phase. Many VOCs contained in gas streams generate odours and, for a given process, in most cases there is a direct correlation between the concentration of VOCs and amount of odorimetric units in accordance with European Standard EN13725, Air quality – determination of odour concentration by dynamic olfactometry.

“Once this correlation has been determined, a Falco PID can be useful for easy online monitoring of VOCs and indirectly of odorimetric units on outlet conveyed gas streams.

Roberto continues: “In Italy, a new legislation with specific odour limit thresholds has also been recently introduced making it ever more important for companies that have treatment in their processes to monitor and improve the treatment efficiency of their systems in line with regulatory requirements.

Most gas streams cause condensation. Although T&A’s OSMOTREFF incorporates a feature that can dilute the gas sample in order to avoid this, it can still occur – so it’s essential to have an instrument with condensation-resistant design.

A 0-3000 parts per million (ppm) detection range can cover most petrochemical applications. For other applications, 0-1000 ppm may be suitable.

The Falco PID operates in conjunction with T&A’s OSMOTREFF system with a pilot test on conveyed gas streams taking from two hours up to several days, depending on the application requirements. Data from the Falco PID is easily recorded and downloaded using a USB memory stick and then loaded in a PC for viewing and processing.