Article provided by CODEL International Ltd. Find out more at codel.co.uk

In most road tunnels there are ventilation systems installed of which there are three main types:

- Longitudinal ventilation

- Cross ventilation

- Longitudinal and cross ventilation

The air speed through a tunnel can be measured with an anemometer. This parameter can be incorporated in a form of closed-loop control to modify the behaviour of ventilation.

Ventilation in road tunnels has three main objectives:

- To protect users as much as possible in case of a fire in the tunnel

- To limit pollutant levels within the tunnel

- To provide good dispersion conditions for pollutants

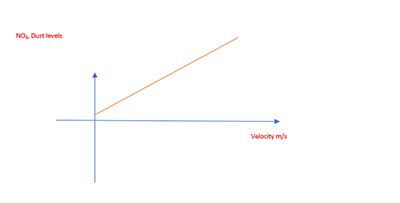

Pollution

Ventilation dilutes the tunnel air by bringing in fresh air. Depending on pollutant concentrations (e.g. NO₂, dust, and so on) the ventilation fan will increase or decrease its speed appropriately. The set point is determined from the air-flow measurement of the anemometer. The polluted air is pushed towards one or the other of the entrances of the tunnel.

Fire

For each fire position and different values of back pressure, it is important to modify the air speed via the control of the ventilation system. Again, this is achieved very accurately using anemometers.

Example:

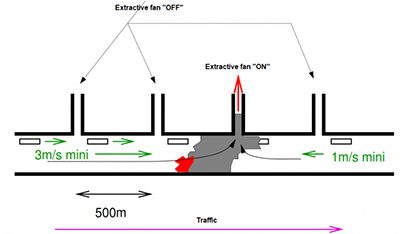

Extractive fans

The violet arrow shows the traffic direction. It means that all cars arriving at the point where the fire is underway are stopped. All extractive fans not in the ímmediate vicinity of the fire are << OFF >>. The fan nearby allows for the removal of smoke via the labelled exit (red arrow) to protect people. An velocity of 3 m/s means the smoke won’t find its way back to the stationary cars. The 1 m/s air flow in the opposite direction acts as a barrier to the smoke. As the above image shows, the 3 m/s and 1 m/s airflows are in opposite directions, and an anemometer is required for airflow direction measurement.

Savings

The amount of power used by the fan can fluctuate from 45 kW to 200 kW, so controlling the fan by using an anemometer is important in reducing the power consumption and cost involved.

Conclusion

Tunnel ventilation systems maintain a sufficient throughput of air to ensure a safe environment for those passing through the tunnel. These systems consume large amounts of power and need to be operated as efficiently as possible.

Article provided by CODEL International Ltd. Find out more at codel.co.uk