A promising filip for the possibility of smaller, more power-efficient and simpler non-dispersive infrared (NDIR) sensors is the announcement by Swiss researchers in September of the development of the first fully-integrated NDIR sensor enabled by specially engineered synthetic materials known as metamaterials. The sensor has no moving parts, requires little energy to operate and is among the smallest NDIR sensors ever created.

It is presented as ideal for Internet of Things and smart home devices that detect and respond to changes in the environment. It could also find use in future medical diagnostics and monitoring equipment.

“Our sensor design unites simplicity, robustness, and efficiency. Using metamaterials, we can omit one of the main cost drivers in NDIR gas sensors, the dielectric filter, and simultaneously reduce the size and energy consumption of the device,” said Alexander Lochbaum from the Institute of Electromagnetic Fields of ETH Zurich, Switzerland, and lead author on the paper, commenting in an article on the website phys.org. “This makes the sensors viable for high-volume, low-cost markets such as automotive and consumer electronics.”

NDIR sensors are used in a multitude of applications including assessing vehicle exhaust, measuring air quality, detect gas leaks and support a variety of medical, industrial and research applications. The new sensor’s small size, potentially low cost, and reduced energy requirements open new opportunities for these and other types of applications.

Shrinking the optical pathway

Conventional NDIR sensors work by shining infrared light through air in a chamber until it reaches a detector. An optical filter positioned in front of the detector eliminates all light except the wavelength that is absorbed by a particular gas molecule so that the amount of light entering the detector indicates the concentration of that gas in the air. Though most NDIR sensors measure CO2, different optical filters can be used to measure a range of other gases.

In recent years, engineers have replaced the conventional IR light source and detector with microelectromechanical systems (MEMS) technology, miniscule components that combine mechanical and electrical aspects. In the new work, researchers integrate metamaterials onto a MEMS platform to miniaturize the NDIR sensor and dramatically enhance the optical path length.

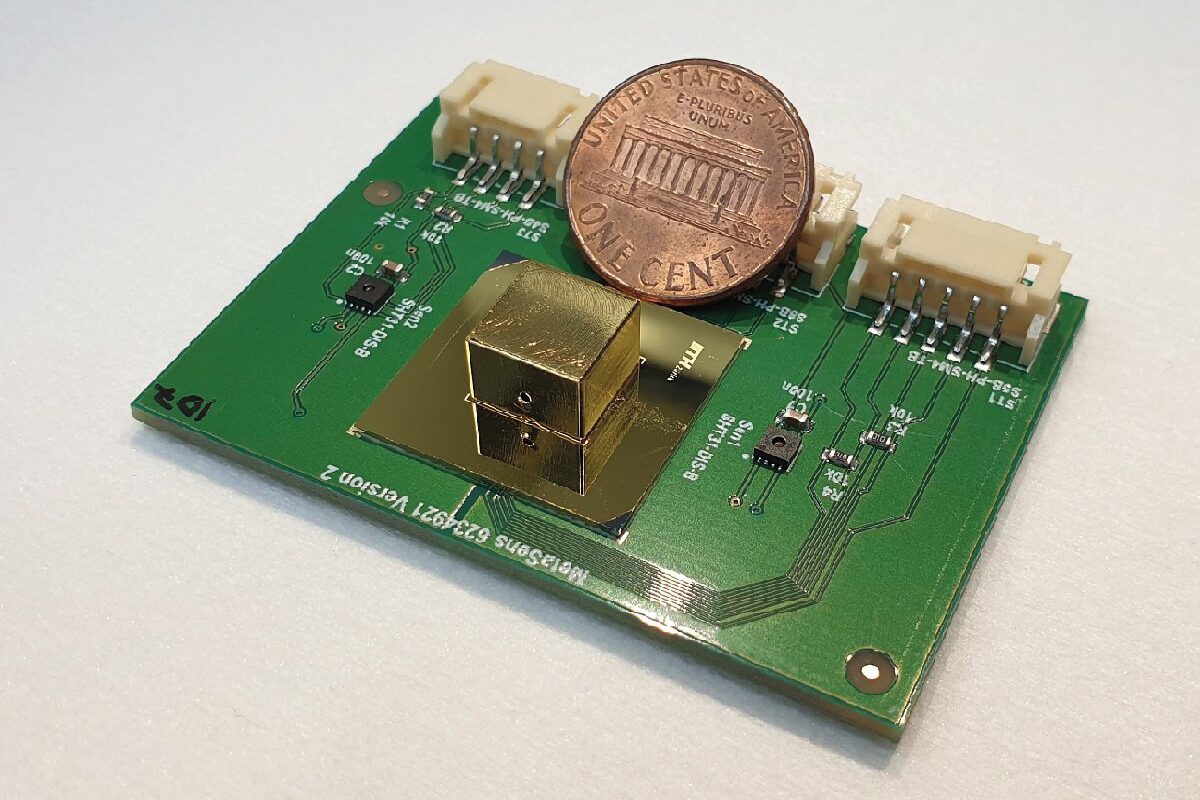

Key to the design is a type of metamaterial known as a metamaterial perfect absorber (MPA) made from a complex layered arrangement of copper and aluminum oxide. Because of its structure, MPA can absorb light coming from any angle. To take advantage of this, the researchers designed a multi-reflective cell that “folds” the infrared light by reflecting it many times over. This design allowed a light absorption path about 50 millimeters long to be squeezed into a space measuring only 5.7 × 5.7 × 4.5 mm.

Whereas conventional NDIR sensors require light to pass through a chamber a few centimeters long to detect gas at very low concentrations, the new design optimizes light reflection to accomplish the same level of sensitivity in a cavity that is just over half a centimeter long.

By using metamaterials for efficient filtering and absorption, the new design is both simpler and more robust than existing sensor designs. Its main parts are a metamaterial thermal emitter, an absorption cell, and a metamaterial thermopile detector. A microcontroller periodically heats up the hotplate, causing the metamaterial thermal emitter to generate IR light, which travels through the absorption cell and is detected by the thermopile. The microcontroller then collects the electronic signal from the thermopile, and uses it to provide a measurement.

The primary energy requirement comes from the power needed to heat the thermal emitter. Given the efficiency of the metamaterial used in the thermal emitter, the system works at much lower temperatures than previous designs.

The researchers tested the device’s sensitivity by using it to measure varying concentrations of carbon dioxide in a controlled atmosphere. They demonstrated it can detect carbon dioxide concentrations with a noise-limited resolution of 23.3 parts per million, a level on par with commercially available systems. However, to do this the sensor required only 58.6 millijoules of energy per measurement, about a five-fold reduction compared to commercially available low-power thermal NDIR carbon dioxide sensors.