“Smart Maintenance. Fast and Simple”

SEEPEX, a global leader in the design, manufacture and application of progressive cavity (PC) pumps, macerators and digital technology, says it is continuing to extend its world-class portfolio of maintain-in-place pump technologies.

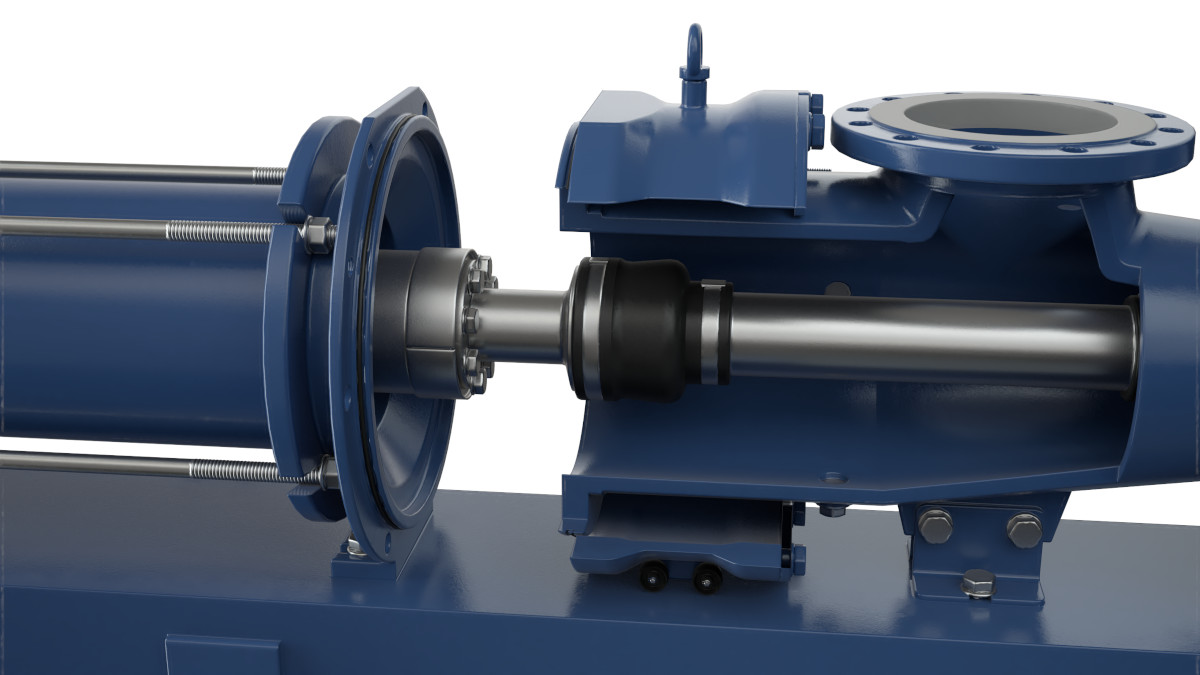

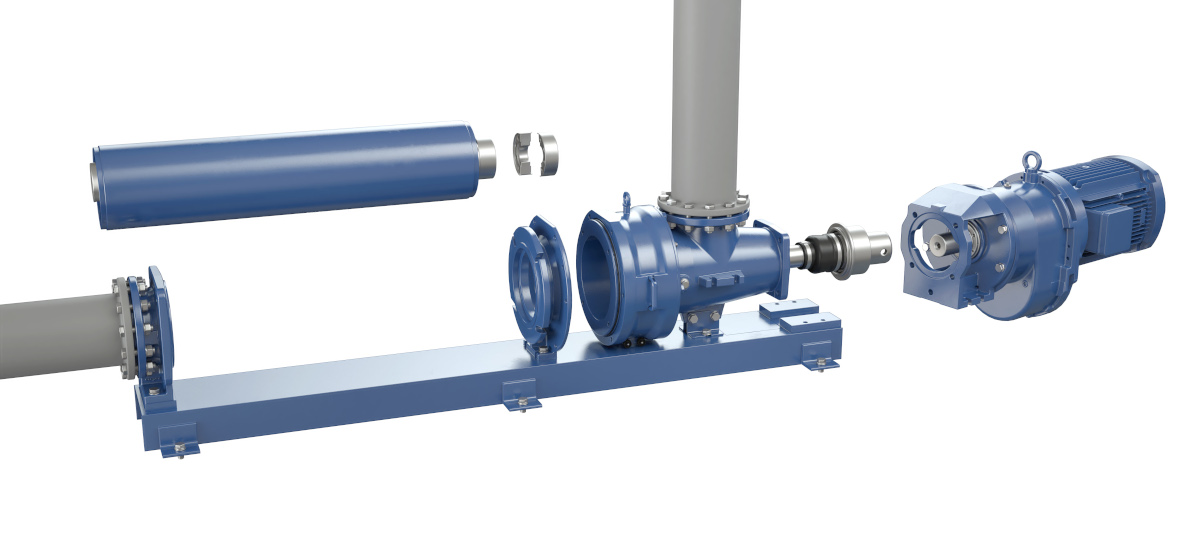

The new patented BNM range of pumps with capacities up to 300 m3/hr and discharge pressures up to 48 bar can handle flowable to highly viscous products with a high dry-solids content. The design features a suction casing that enables quick and easy access for rotor and stator removal without having to dismantle the rotor side joint. As a result, maintenance time can be reduced by up to 80% with a significant reduction in maintenance cost.

The suction casing and pressure branch remain in place, eliminating the need for pipework dismantling. The pump drive can then be quickly removed complete with mechanical seal, drive-side universal joint and coupling rod.

Unique patented solution

SEEPEX new ease-of-maintenance solution for big pumps complements the firm’s Smart Conveying Technology (SCT), launched in 2008 and “still setting standards in the maintenance of smaller standard progressive cavity pumps, and Drive Joint Access (DJA) technology for open hopper pumps”, says the firm. All of these patented solutions increase uptime and plant availability.