This article contains paid for content produced in collaboration with FLIR

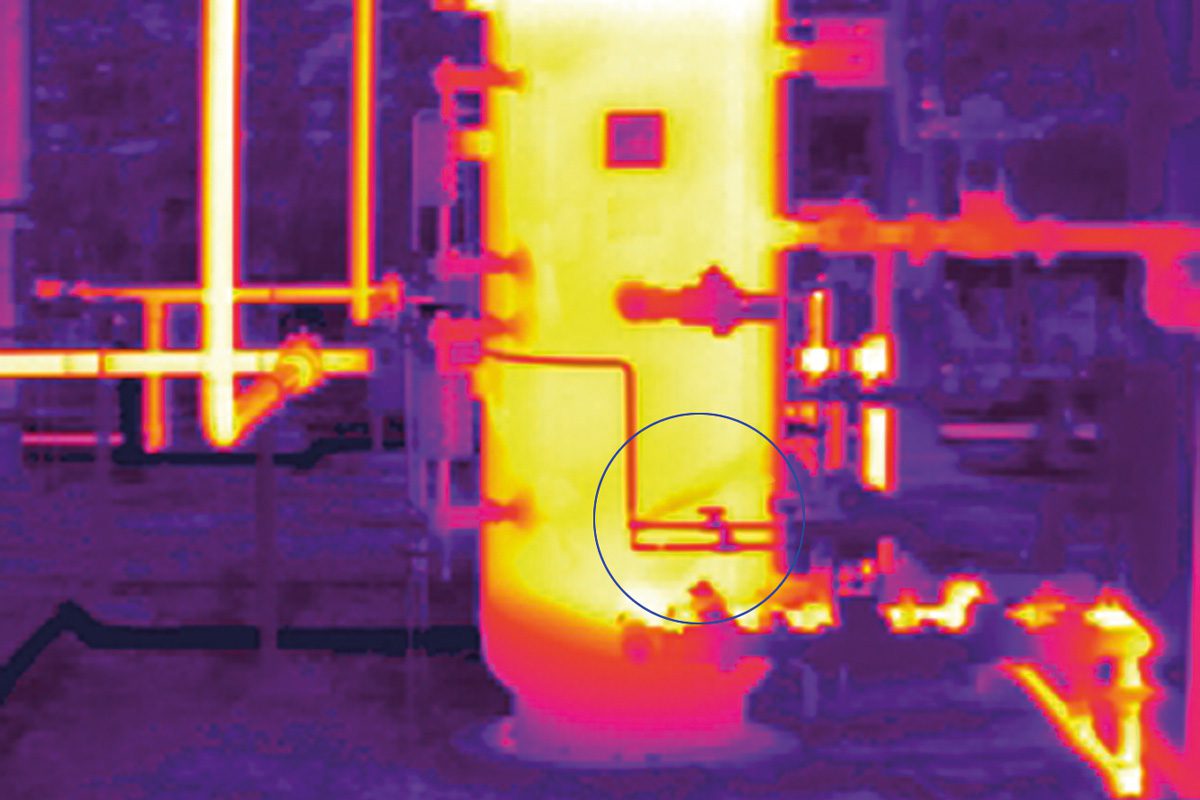

Optical Gas Imaging (OGI) Cameras utilize infrared sensors to detect and visualize methane, sulphur hexafluoride, and hundreds of other industrial gases, which appear as plumes of smoke in a thermal image or video.

In comparison, a toxic vapour analyzer, or sniffer, can only detect gas by placing the probe directly on the equipment component, inspecting one point at a time. It takes days to test an entire site using a sniffer. An OGI camera inspects thousands of points in a single survey, enabling faster inspections, leak source identification, and greater situational awareness.

When using approved OGI cameras, customers in the US fully satisfy EPA specifications.

In fact, the EPA has stated that OGI is the “best system of emission reduction,” as it allows operators to both see the smallest concentrations of gas as well as large leaks. By quickly detecting gas leaks so that repairs can be made, OGI cameras help lower the risk of plant shutdowns, regulatory fines, and product loss—all of which lead to a higher return on investment for oil and gas companies.

Another advantage of using an OGI camera is that it is a non-contact measurement technology, creating better safety protocols for employees. Inspectors can scan difficult to monitor (DTM) live equipment with an OGI camera, standing considerable distances away from the asset. Placing greater distance between employees and hazardous components protects their health and wellbeing.