Metal organic frameworks (MOFs) could take acid-gas sequestration to the next level, and offer a practical approach to improving air quality, says a group from Oak Ridge National Laboratory, which is tuning these devices to trap gases like NO2 and SO2.

Seemingly at the leading edge of innovation in the field of air pollution and climate change mitigation are efforts to develop materials that can detect and trap pollutant gases. In some cases, captured molecules might also be stored and reused.

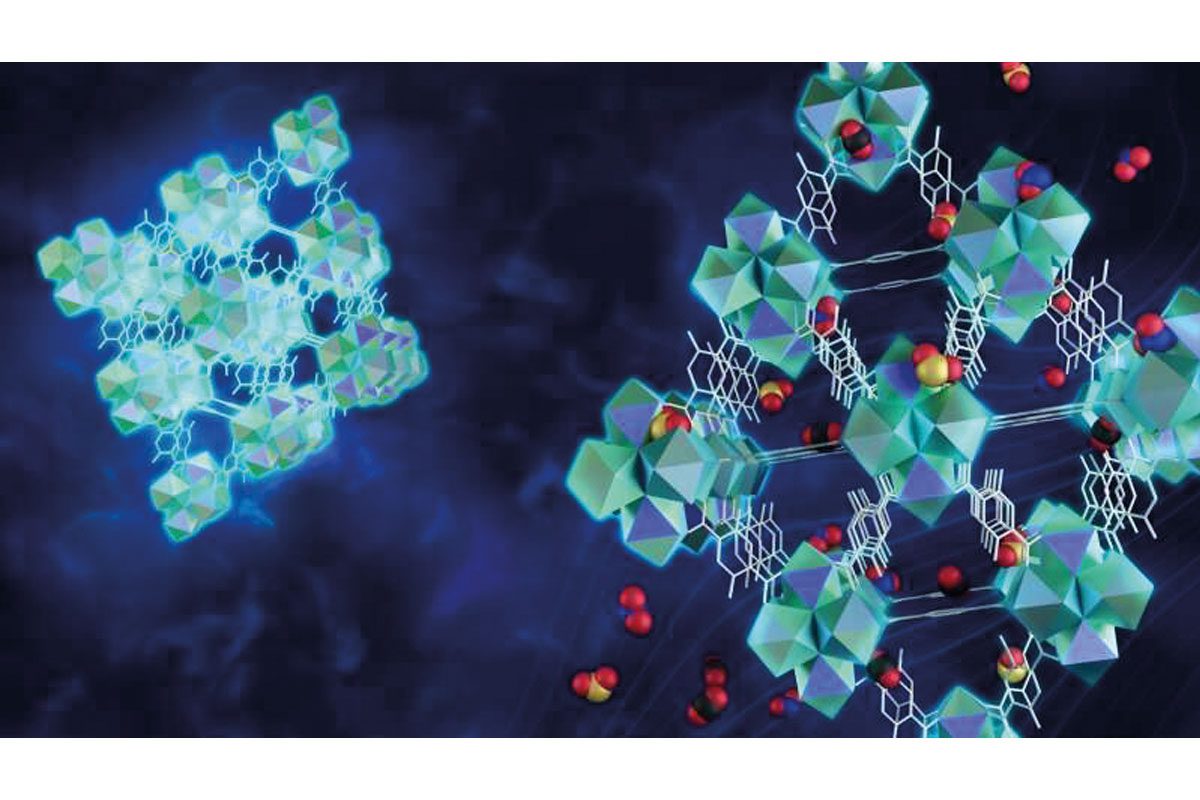

Materials called metal organic frameworks, or MOFs,are the underpinning of the approach. MOFs essentially comprise a matrix of metal atoms attached to each other by organic molecules and forming a repeating pattern of tiny, interconnected metal cages. It acts like a sponge that can cause molecules to adhere to its surface. In fact, MOFs are so highly porous that an amount capable of being fitted inside someone’s pocket would, if stretched out, cover the surface of an entire football field.

Tuning MOFs for NO2 and SO2

In a recent study published in the journal ACS Applied Materials and Interfaces, researchers searching for candidate materials to remediate NO2 and SO2 pollution investigated a series of MOFs that can be made from the entire family of rare-earth metals. They used computer simulations and a combination of neutron and x-ray scattering experiments to help them determine the optimal conditions for synthesizing the materials. In the process, they also uncovered important details about an interesting defect that forms in the MOFs that they say could be useful in building devices for capturing emissions or sensing dangerous levels of toxic gases.

“Metal organic frameworks are really novel in their flexibility, their chemistry, and how you can tailor their structure. If you swap out organic molecules, you can tune the structure to target different gases,” said Sandia National Laboratory’s Susan Henkelis, the study’s lead author. “Acid gases typically come from combustion processes, so this research could be useful in developing devices to help limit emissions from large-scale industrial facilities like oil refineries and fossil fuel-based power plants.”

The team includes researchers from the Department of Energy’s (DOE) Sandia and Oak Ridge national laboratories (ORNL) and the University of Tennessee, Knoxville (UTK). The researchers are part of the Centre for Understanding and Control of Acid Gas-Induced Evolution of Materials, or UNCAGE-ME, a program developed specifically to understand the interactions between acid gases and solid materials. UNCAGE-ME is part of a broader research effort supported by DOE’s Energy Frontier Research Center (EFRC) program, which brings together the research capabilities of universities and national laboratories to provide atomic-scale insights into tackling some of the world’s biggest energy challenges that can only be achieved through large collaborations.

Tunable Structures

MOFs have nanosized pores and selectively adsorb gases, in a manner comparable to a sponge. They are ideal for use in sensor arrays because of their tunability, enabling engineers to use a diverse set of materials that allows an array of MOF-based sensors to deliver detailed information.

Depending on which components make up a gas, different amounts of the gas will adsorb in each MOF. That means the composition of a gas can be inferred by measuring the adsorbed gas in the array of MOFs using micro-scale balances.

A challenge is that all MOFs adsorb all gases – not to the same extent, but nevertheless the absence of perfect selectivity prevents an engineer from simply saying, “let’s just dedicate this MOF to carbon dioxide, that one to sulphur dioxide, and another one to nitrogen dioxide.”

Understanding the chemistry

“The fundamental science objective of this work was aimed at understanding how the chemistry and the synthesis process creates these defects, because we want to know how the defects can be controlled and what their affect is on adsorption of acid gases,” said Peter Metz, a researcher at UTK. “To do that, we need to understand how the atomic bonds in the MOFs form and how the atoms are arranged.”

Ideally, the cages inside each synthesized MOF form a cube. Each corner contains a cluster of six rare-earth metal ions with another cluster in the center of the cube. Each pair of metal ions in the cluster connects to another pair in another cluster by a single link, or linker molecule.

But sometimes a defect occurs, where the linker kinks and exposes the rare-earth ion, which increases the likelihood that a pollutant molecule will become trapped within the structure.

To find out why this happens, the researchers used a combination of neutron and x-ray scattering experiments to map the materials’ atomic structures.

They used x-rays to find the heavy metal elements, which provided an outline of the overall structure. And, to better understand how the organic molecules are arranged, they bombarded the materials with neutrons using the POWGEN instrument at ORNL’s Spallation Neutron Source (SNS), which helped them track the positions of the hydrogen, carbon, and oxygen atoms that form the molecular bonds between the metal ion clusters.

From the experiments, the team was able to determine that the materials with the defects actually formed more rapidly than their defect-free counterparts. They also discovered the defects could be intentionally induced by adjusting the temperatures and the time it takes to grow the crystalline materials.

The team then used the structural data obtained from the experiments to run computer simulations to see how each of the materials—with and without the defects—interacted with the toxic gases NO2 and SO2.

“While these new insights are on the basic research side of things, they could have a big impact down the road,” said Sandia’s Tina Nenoff, the study’s author. “We learned new information about how these materials form, which we can use to control and design MOFs with more specificity. And furthermore, we developed a comprehensive approach to evaluating large series of MOFs, which will help expedite the pace of finding new candidate materials and developing them in useful technologies.”