Large pieces of plastic can break down into nanosized particles that often find their way into soil and water. Perhaps less well known is that they can also float in the air. It’s unclear how nanoplastics impact human health, but animal studies suggest they’re potentially harmful. Researchers have developed a sensor that detects these particles and determines the types, amounts and sizes of the plastics using colourful dot films.

Nanoplastics are a major concern if they’re in the air that you breathe, getting into your lungs and potentially causing health problems,” says Raz Jelinek, the project’s principal investigator. A simple, inexpensive detector could have huge implications, he suggested, speaking at an August meeting of the American Chemical Society (ACS).

Some of the particles shed by plastic waste are so small — generally less than 1-µm wide — and light that they can even float in the air, where people can then unknowingly breathe them in. Animal studies suggest that ingesting and inhaling these nanoplastics may have damaging effects. Therefore, it could be helpful to know the levels of airborne nanoplastic pollution in the environment.

Jelinek’s team at Ben-Gurion University of the Negev have previously developed an e-nose for monitoring the presence of bacteria by adsorbing and sensing the unique combination of gas vapour molecules that they release. The researchers wanted to see if this same carbon-dot-based technology could be adapted to create a sensitive nanoplastic sensor for continuous environmental monitoring.

Carbon dots are formed when a starting material that contains lots of carbon, such as sugar or other organic matter, is heated at a moderate temperature for several hours, says Jelinek. This process can even be done using a conventional microwave. During heating, the carbon-containing material develops into colourful, and often fluorescent, nanometer-size particles called “carbon dots.” And by changing the starting material, the carbon dots can have different surface properties that can attract various molecules.

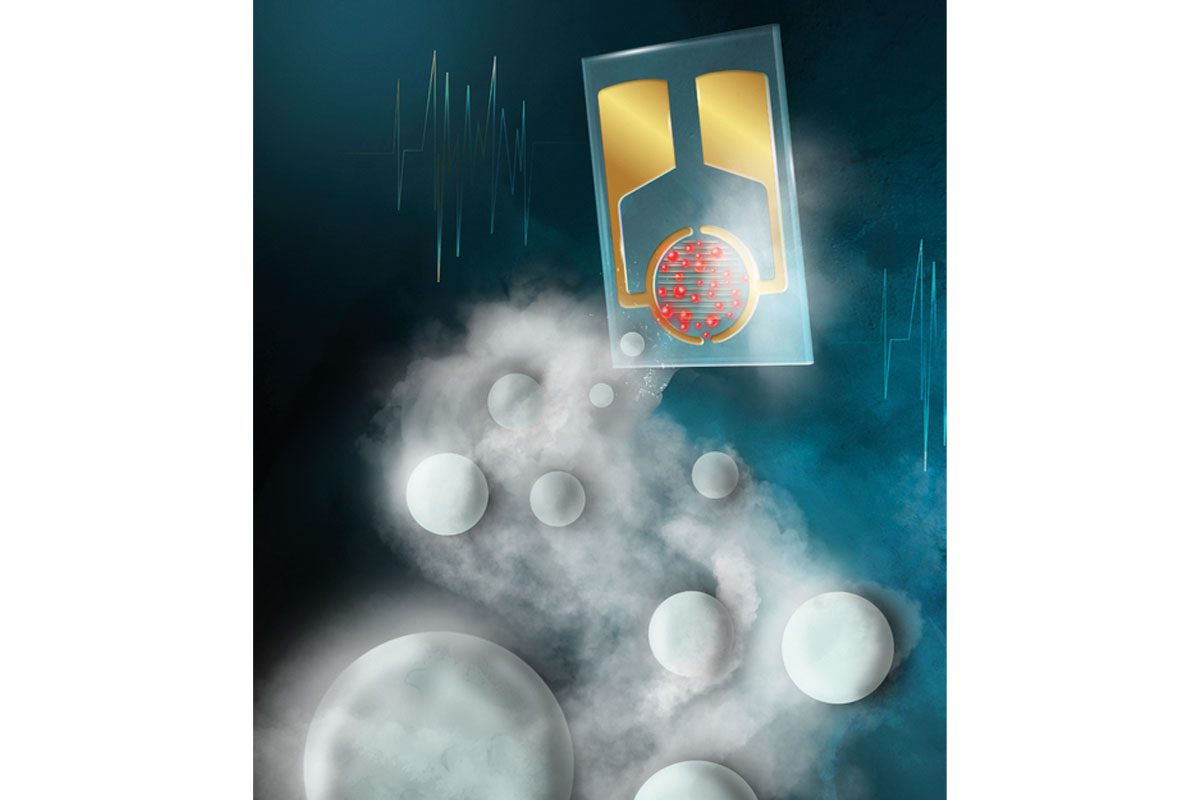

To create the bacterial e-nose, the team spread thin layers of different carbon dots onto tiny electrodes, each the size of a fingernail. They used interdigitated electrodes, which have two sides with interspersed comb-like structures. Between the two sides, an electric field develops, and the stored charge is called capacitance. “When something happens to the carbon dots — either they adsorb gas molecules or nanoplastic pieces — then there is a change of capacitance, which we can easily measure,” says Jelinek.

Then the researchers tested a proof-of-concept sensor for nanoplastics in the air, choosing carbon dots that would adsorb common types of plastic — polystyrene, polypropylene and poly(methyl methacrylate). In experiments, nanoscale plastic particles were aerosolized, making them float in the air. And when electrodes coated with carbon-dot films were exposed to the airborne nanoplastics, the team observed signals that were different for each type of material. When polystyrene particles in three sizes — 100-nm wide, 200-nm wide and 300-nm wide — were aerosolized, the sensor’s signal intensity was directly related to the particles’ size.

The team’s next step is to see if their system can distinguish the types of plastic in mixtures of nanoparticles. Jelinek said it’s likely that they could tweak the nanoplastic sensor to differentiate between additional types and sizes of nanoplastics.