This article contains paid for content produced in collaboration with Stonegate Instruments.

This article contains paid for content produced in collaboration with Stonegate Instruments.

Given the stringent health and safety and environmental regulations in place, businesses are looking to system suppliers who know the value – both in terms of safety and efficiency – of early gas detection. At the cutting-edge of these systems is Stonegate Instruments, a leading designer and manufacturer of solutions to reduce refrigerant gas leaks and ensure safety in cold storage and industrial refrigeration. Managing Director, Shaun Evers, shares his thoughts on the symbiotic relationship of safety and efficiency that drives Stonegate’s operations.

Considering that refrigeration systems are essential to organisations across the commercial and industrial sectors, and given that most leaks won’t be discovered until 60% of the odourless and colourless gas has escaped, real-time solutions derived from the latest in gas detection technology are essential.

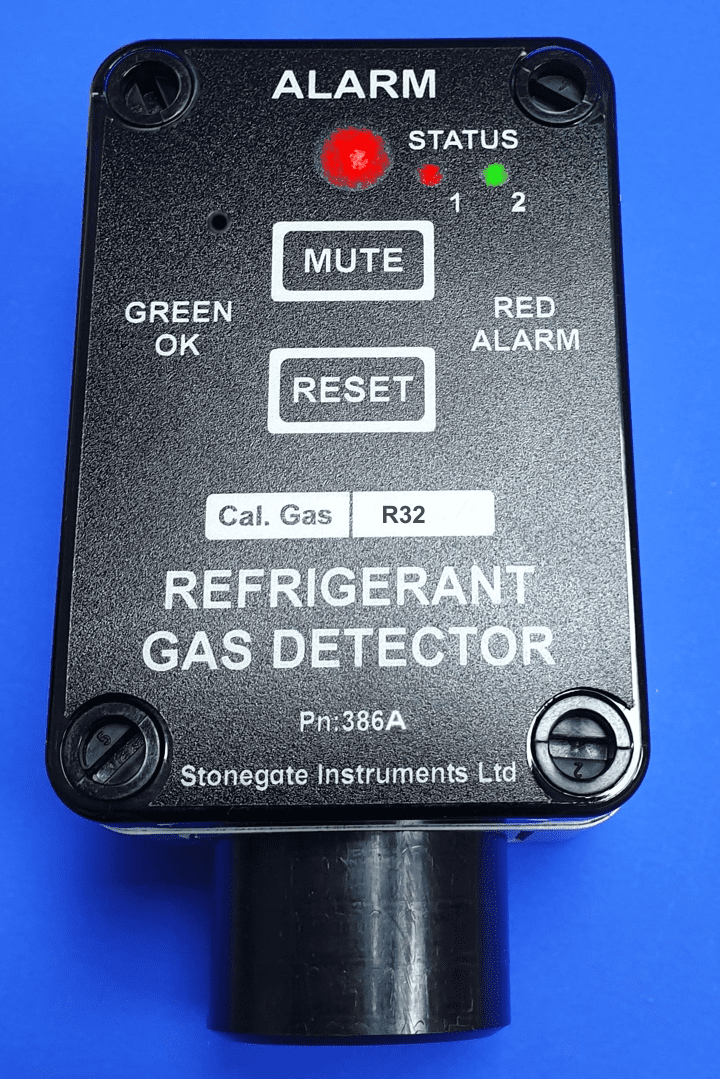

Stonegate Instruments lead the way with their solution – intelligent sensors that have the ability to detect even the most minute traces of gas, offering an immediate warning that eliminates the usual health and safety risks associated with refrigerant gas leaks. This focus on safety and ultimately the protection of personnel is paramount, with systems including integrated safety features such as audio-visual alarms.

Driving efficiency through safety

Not only negating safety risks, the added benefits of Stonegate’s technology are apparent when considering the environmental impact of gas leaks. When a leak occurs, the system must work harder to maintain function, leading to sizable increases in both energy usage and costs.

When investing in Stonegate Instruments’ technology, you are actively working to reduce both your carbon footprint and energy costs, whilst committing to combat serious and potentially damaging risks. As a trusted, experienced leader in gas detection, our systems ensure peace of mind for those working in many commercial and industrial spaces.