This article contains paid for content produced in collaboration with PowerUP.

Politicians, scientists, and industry stakeholders alike are continuously seeking sustainable energy sources as a contribution to the international efforts in reducing greenhouse gas emissions. However, challenges in establishing alternatives to fossil fuels include costs, technology gaps, as well as accessibility and reliability.

Biogas is widely considered as one puzzle piece in the bigger picture of tomorrow’s energy sources: Being produced out of organic waste, it tackles both the problems of waste management and finding renewable energy sources.

However – ”The use of biogas in energy production is hindered by several factors, including a lack of efficiency of many gas engines themselves, which are a centerpiece in the transformation of biogas into heat and energy”, states Thomas Achrainer, one of the founders of PowerUP GmbH. As an established expert for gas engine services regarding biogas power plants, PowerUP has specialized in innovative solutions to get the biogas sector ready for the next decade.

The biogas market today – an overview

Especially in electricity production, biogas has been found as a promising alternative to fossil fuels, which still made up the majority of global energy sources in 2022: Coal alone had a share of more than 35% that year, followed by natural gas with 22%.[1]

Yet, renewable energy sources like biogas are on the rise: In 2022, the capacity of biogas energy installed globally equaled 21.5 gigawatts. In total, the worldwide biogas market – including applications like cooking, heating, and, with the largest share, energy production – was estimated to size USD 65.53 billion in 2023. Between 2024 and 2030, a compound annual growth rate (CAGR) of 4.2% is expected.[2] [3]

Obviously, the direction is clear: Biogas is expected to become an increasingly important factor in global energy supply. Advantages include renewability and waste utilization, but also increased stability in the energy supply of developing countries and rural regions. Still, there is considerable room for improvement.[4]

Major challenges for biogas engine operators: What are the struggles?

“Biogas often needs to undergo a special processing step in order to make it accessible to energy production”, says Thomas Achrainer. After all, this natural product can come with sometimes considerable variation in its composition. But despite advanced processing, biogas engines need to be adaptable enough to cope with inconsistencies during combustion.

However, these are not the only intricacies that biogas engines (or rather, their operators) are confronted with.

Inefficient facilities

Costs are a determining factor when it comes to the adoption of renewable energy sources. Biogas makes no exception, which is why the energy sector needs to have state-of-the-art technologies at its disposal. Speaking of gas engines taking center stage in energy production with biogas, Thomas Achrainer illustrates: “Modern gas engines are real power horses, as they can achieve high efficiency levels when used in energy production. However, even when using gas engines by established market leaders, there is often room for improvement.”

Despite good efficiency levels between 40 and 50%, biogas engines for energy production can be further improved and adapted to specific customer needs. For instance, the tolerance for larger variations in gas quality can be improved, circumventing the need for laborious gas preparation steps.[5]

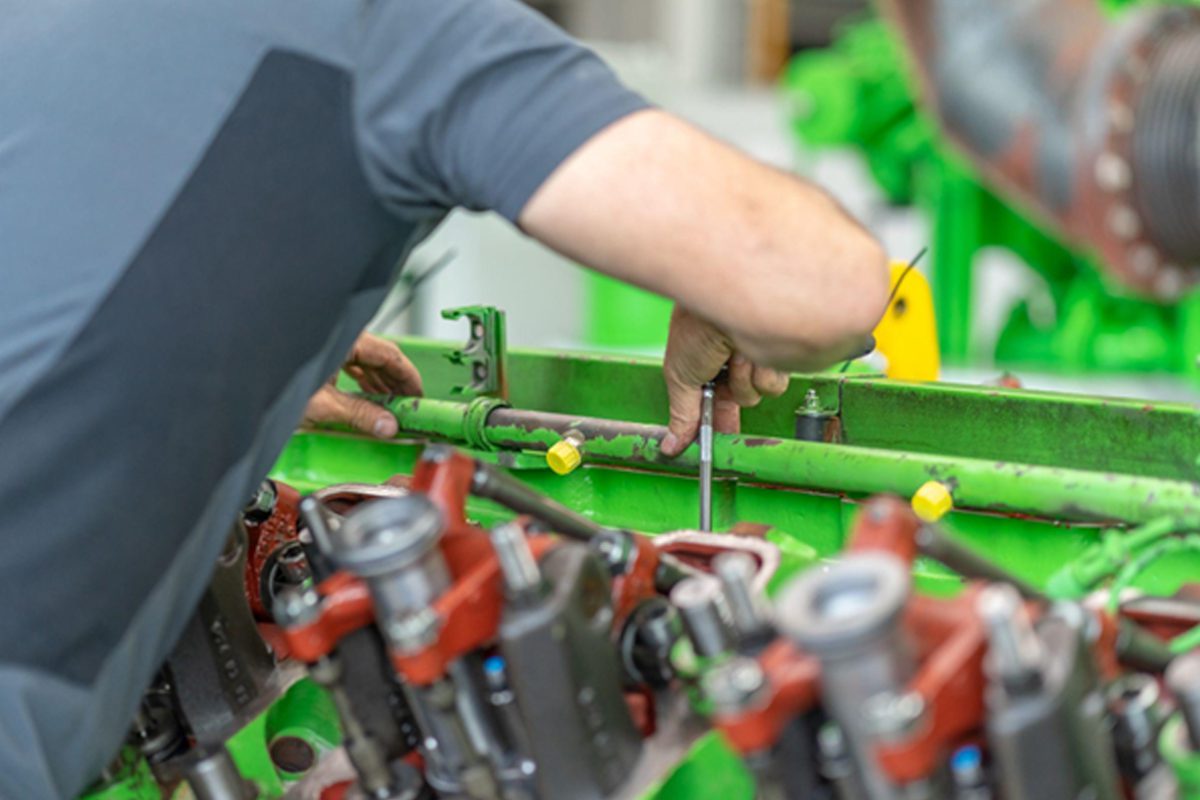

Additionally, specially developed gas engine parts can be incorporated to further increase the efficiency of engines. These elements may include spark plugs, blowby filters, as well as many other components to increase not only efficiency, but also durability.

Complex maintenance

Maintenance can easily become a major issue when operating complex facilities with large and delicate systems. And despite regular servicing being essential to ensure longevity of costly gas engines and to avoid unplanned interruptions, it often comes with significant downtimes. This is even more true when the facility in question is located in considerable distance to either the gas engine manufacturer or a qualified service partner.

Gas engine operators are therefore seeking for possibilities to either decrease the costs and efforts related to maintenance or to combine servicing with customized upgrading of existing systems.

Dated systems – costly replacements

The average lifetime of biogas engines can extend over more than 25–30 years. However, as technology moves on, many power plants have only dated gas engines at their disposal, increasing both maintenance costs and susceptibility to errors. Even so: Replacements are costly, and an untimely phase-out of a gas engine undermines the aspiration of a sustainable energy production.

Keeping track with technological progress, though, does not necessarily imply regularly replacing multiple components of power plants. Instead, possibilities to upgrade existing systems are extremely requested with the aim to make older gas engine generations future-proof.

Powering up biogas engines – being prepared for tomorrow’s challenges

“Challenges drive innovation. Without them, we’d have stagnation instead of progress”, says Thomas Achrainer. And in fact, the hurdles in the operation of biogas engines have prompted the industry to develop approaches to increase efficiency, reliability, and independence.

To that end, PowerUP not only offers maintenance services for MWM® and INNIO Jenbacher® engines in 52 countries – the condition-based overhaul allows cost and resource efficiency by only exchanging those parts that have actually reached the end of their lifetime. Component replacements, on the other hand, also include PowerUP-designed gas engine spare parts that are able to further increase the efficiency and longevity of biogas engines – such as blowby systems and cylinder heads.

In addition to dedicated spare parts and upgrade options for existing engines, PowerUP has also developed PUPGEN: The combination of an overhauled INNIO Jenbacher® Type 3 engine and targeted adaptations by PowerUP makes it an extremely versatile while cost-effective addition to the company’s line-up.

[1] https://www.statista.com/statistics/269811/world-electricity-production-by-energy-source/

[2] https://www.statista.com/statistics/1032922/biogas-capacity-globally/

[3] https://www.grandviewresearch.com/industry-analysis/biogas-market

[4] https://energypedia.info/wiki/Advantages_and_Disadvantages_of_Biogas