Sponsored Content: The right anaerobic digester for your farm

Dr David Kaner, CEO of Advanced Anaerobics Limited (AAL), writes: There are no new ideas, only old ideas whose time has come.

Sponsored Content: Deal expands range of ATEX-certified gas monitor fleet

Ashtead Technology has announced a new partnership with Gas Data, expanding the range of applications for its gas monitors (available for either purchase or rental).

Sponsored Content: Not your average chopper

P&M Pumps writes: Come and get your hands on the real mean machine – visit P&M Pumps Ltd on stand D107 at the World Biogas Expo, the leading global trade show dedicated solely to AD and Biogas on 29-30 March at NEC Birmingham.

Report highlights importance of whole-process appraisal of AD

By Matt Hale

A new report published by the European Biogas Association (EBA) has highlighted that the true benefits of anaerobic digestion (AD) measured across...

AD and Biogas Industry Awards 2023 finalists announced

The finalists for the 2023 AD and Biogas Industry Awards have been announced. Run by the Anaerobic Digestion and Bioresources Association (ADBA) and the...

Low-cost digester additive for nitrogen-rich AD feedstocks

Sponsored content: To better support biogas plants processing high levels of nitrogen-rich feedstock, AD experts FM BioEnergy will launch a new low-cost version of their ammonium inhibitor digester additive on Stand C109 at the World Biogas Expo 2023.

Milestone for biomethane injection in Northern Ireland

A seemingly significant milestone was confirmed on 16 February for the gas grids in Northern Ireland which will see the injection of biomethane into...

High-efficiency progressive cavity pump aimed at biogas

With a declared focus on energy-efficient systems and components that optimise the operation of existing biogas plants and contribute to a higher gas yield,...

Biogas trade bodies and companies call for an urgent rethink on GHG Protocol guidance...

Over 50 biogas and biomethane trade associations and companies from around the world have written to the World Resources Institute (WRI), administrator of the Greenhouse Gas Protocol,1 calling...

Sponsored Content: Major WWTW project sees Gen-C upgrade six biogas engines in an industry...

Gas engine upgrading specialist Gen-C is working with service provider WB Power Services (WBPS) to upgrade six biogas combined heat and power (CHP) engines at wastewater treatment sites across the north of England

Against the grain: What can be done about microplastics in soils and digestate?

Microplastics are everywhere: We know that much. But should we be worried? What can we do about it? Some of the speakers at Aqua Enviro's European Biosolids and Bioresources Conference, in late November, presented findings from a project aiming to understand the levels of this contaminant in compost and AD digestate. A change in the policy landscape seems imminent, as Envirotec found out.

Anaerobic digestion sector to see taxes rise by up to 30%

Operators of both gas to grid and electrical AD plants are facing higher business rates after the UK government changed the way it calculates...

Sponsored Content: More demand for complete system solutions

By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

Sponsored Content: ADBA National Conference 2022 to make the business case for anaerobic digestion...

Faced with the energy crisis currently affecting not just the UK but much of the world, the British government is overlooking the gift that is anaerobic digestion (AD), despite the business case for AD development growing stronger by the day.

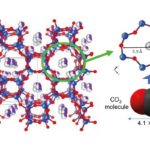

Selective adsorption

A novel biogas purification system is currently under trial in the Japanese city of Kurashiki.

Efficiency first

That should be the focus for ensuring growth of the biogas sector in Ireland, explains Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers.

Pre-treatment boosts efficiency of converting sewage to biogas

A research team from Washington State University has tested a pretreatment technology that they say improves the conversion of sewage sludge to biogas.

The approach...

California utility selects thermal hydrolysis systems for biosolids digesters

San Francisco Public Utilities (SFPUC) has selected three Cambi thermal hydrolysis technology systems for new biosolids digester facilities. The technology will allow the SFPUC...

Magnetic field boosts biogas production

A magnetic field can help enhance the generation of synthetic biogas, according to new research.

Sponsored Content: Biogas production landmark

Scottish Water's treatment centre near Aberdeen is currently leading the way as a centre of excellence for biogas production (from sludge), with its dedicated team tirelessly focused on improving efficiencies.